Soot measurement system and soot measurement method by extinction method with pre-positioned light source

A measurement system and extinction method technology, applied in the direction of measurement device, transmittance measurement, scattering characteristic measurement, etc., can solve the problems of limited incident light absorption ability, large experimental error, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

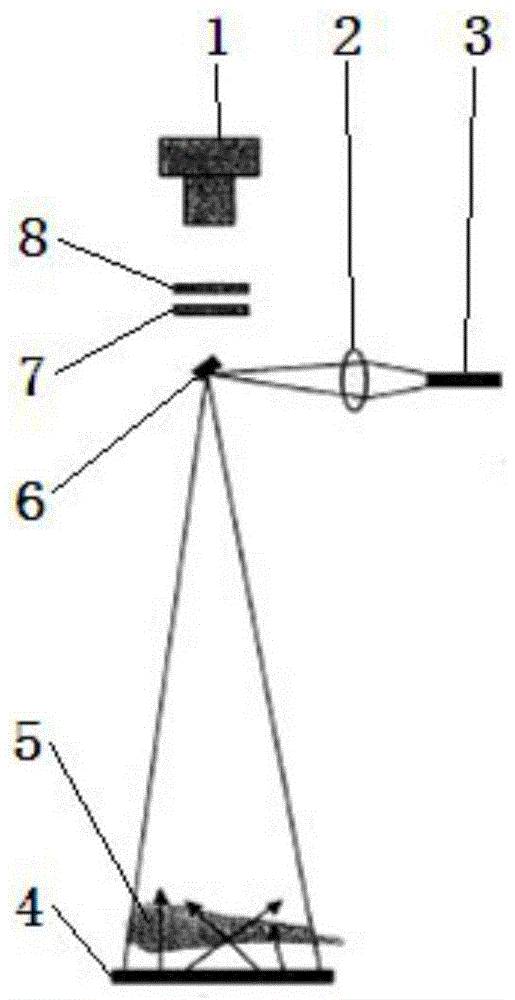

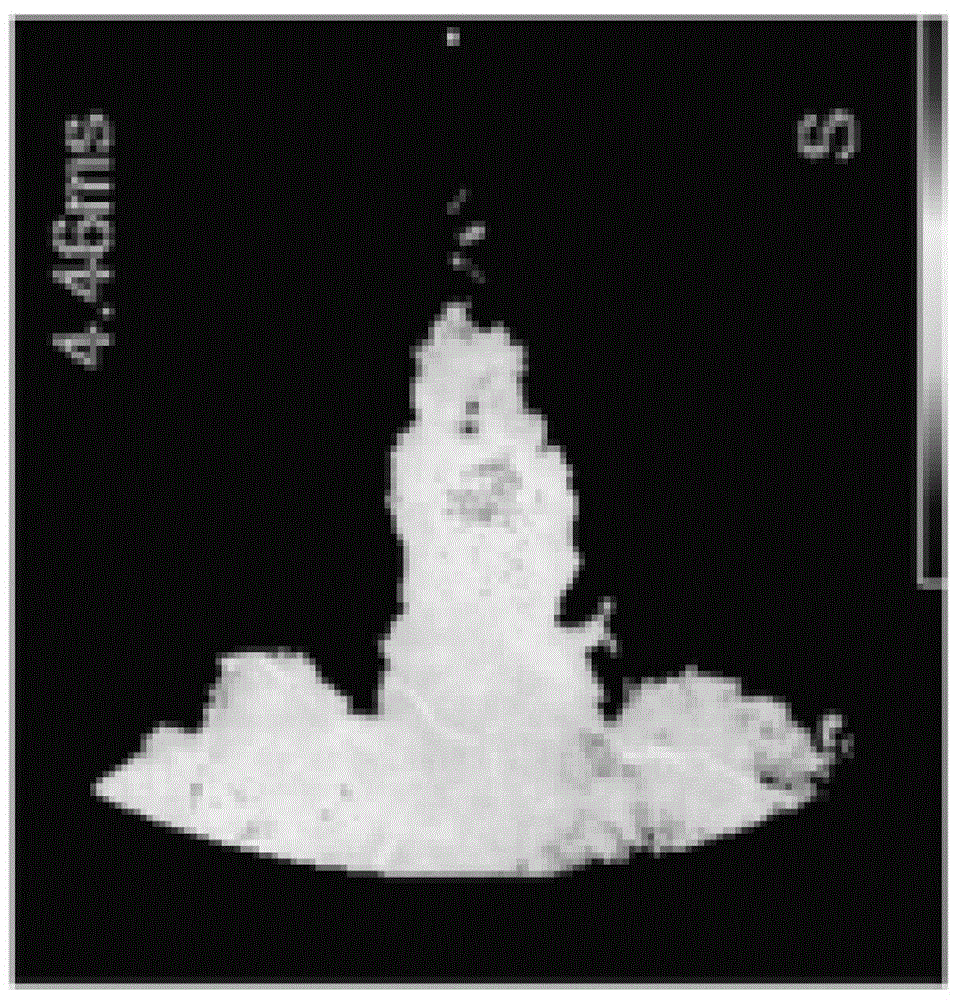

[0037] The structure and working principle of a soot measurement system with extinction method in front of the light source will be further described below in conjunction with the accompanying drawings.

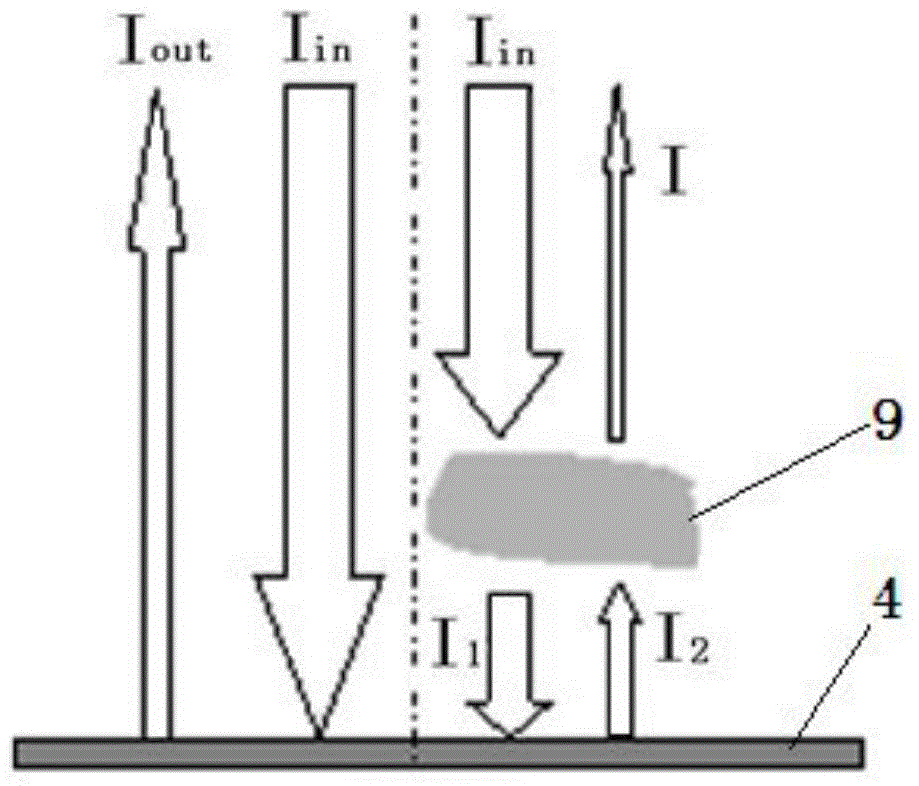

[0038]The measurement scheme is composed of high-speed camera 1, ND light reduction lens 7, interference filter lens 8, reflector 6, laser light source 3, lens 2 and light scattering disc 4; its relative arrangement position is: interference filter lens 8 and ND The light reduction lens 7 forms an optical window and is sequentially placed on the lens front end of the high-speed camera 1, the reflector 6 is placed directly in front of the ND light reduction lens 7 at an angle of 45°, the laser light source 3 is placed in the horizontal incident angle direction of the reflector 6, and the lens 2 is placed between the laser light source 3 and the reflector 6, and the light scattering disc 4 is fixed on the bottom of the burning oil beam 5 in the direction of the vertical reflecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com