BIM-based intelligent train whole-vehicle service life prediction method and system thereof

A service life and prediction method technology, applied in the direction of railway vehicle testing, etc., can solve problems such as the decline of prediction accuracy and the inability to accurately model the service life of trains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

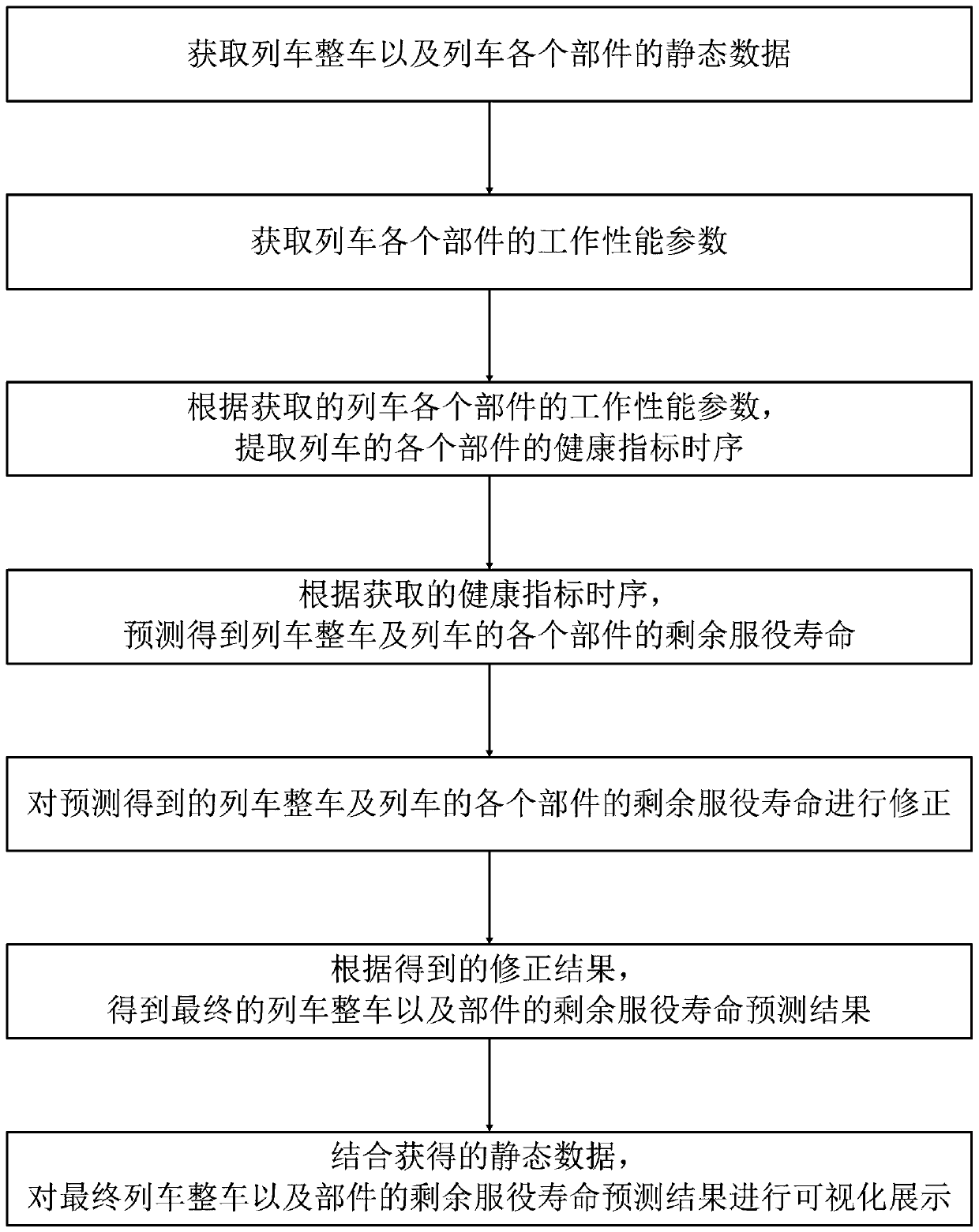

[0076] Such as figure 1 Shown is the method flow diagram of the method of the present invention: this BIM-based intelligent train vehicle service life prediction method provided by the present invention comprises the following steps:

[0077] S1. Obtain the static data of the complete train and each component of the train; specifically, the following steps are used to obtain the static data:

[0078] Ⅰ. Divide the whole train into the following components: running part, hook and buffer device, car body, traction system, air conditioning system, braking system and pantograph;

[0079] Ⅱ. In the design stage, obtain the three-dimensional model, model, parameter and maintenance history data of the whole train and each part of the train;

[0080] Ⅲ. In the operation and maintenance phase, obtain the maintenance type data and maintenance content data after each maintenance of the train, and simultaneously update the 3D model, model, parameter and maintenance history data of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com