Random error modeling and compensation method for ring laser device based on adaptive Kalman filtering

An adaptive Kalman and ring laser technology, applied in the field of inertial calibration, can solve the problems of ring laser calibration accuracy degradation, affecting the accuracy of state equations and measurement equations, etc., to reduce model errors, eliminate the influence of random noise, and improve calibration The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

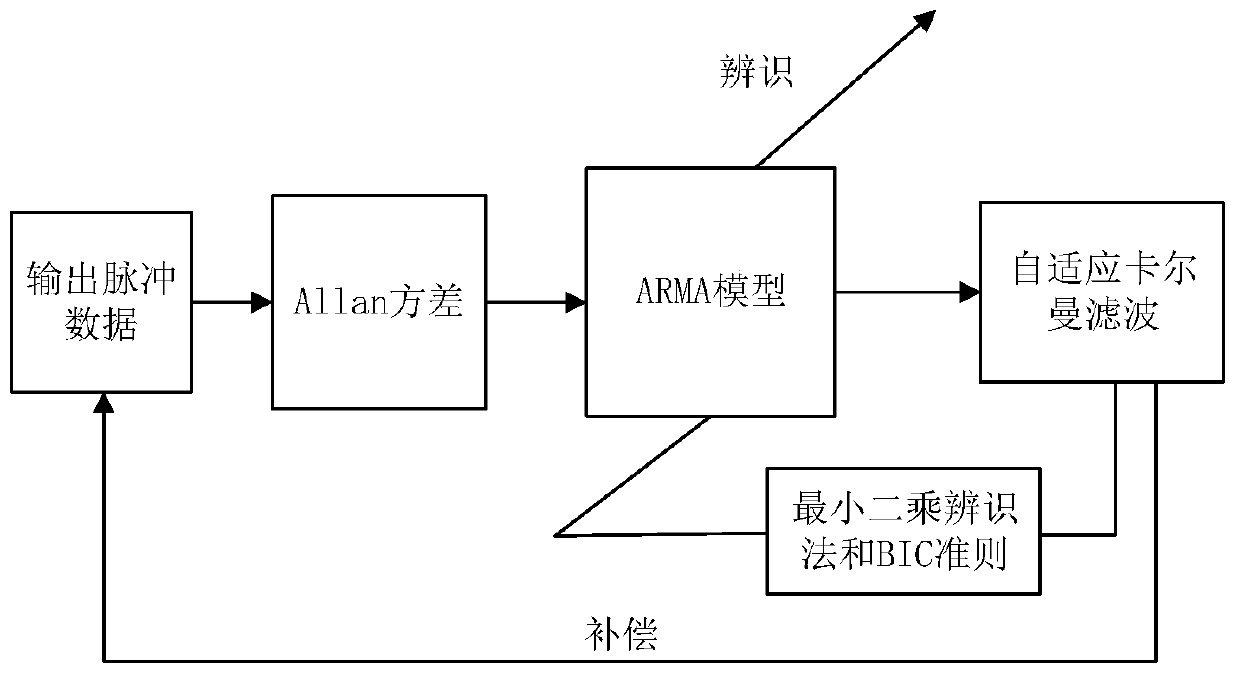

[0053] In this embodiment, according to the method described in the content of the invention, the ring laser is used to calibrate the servo turntable, and a random error modeling and compensation method based on adaptive Kalman filtering is designed, which eliminates the influence of random noise on the ring laser and improves the Calibration accuracy.

[0054] Random error modeling and compensation methods based on adaptive Kalman filtering, such as figure 2 As shown, it is mainly divided into the following steps:

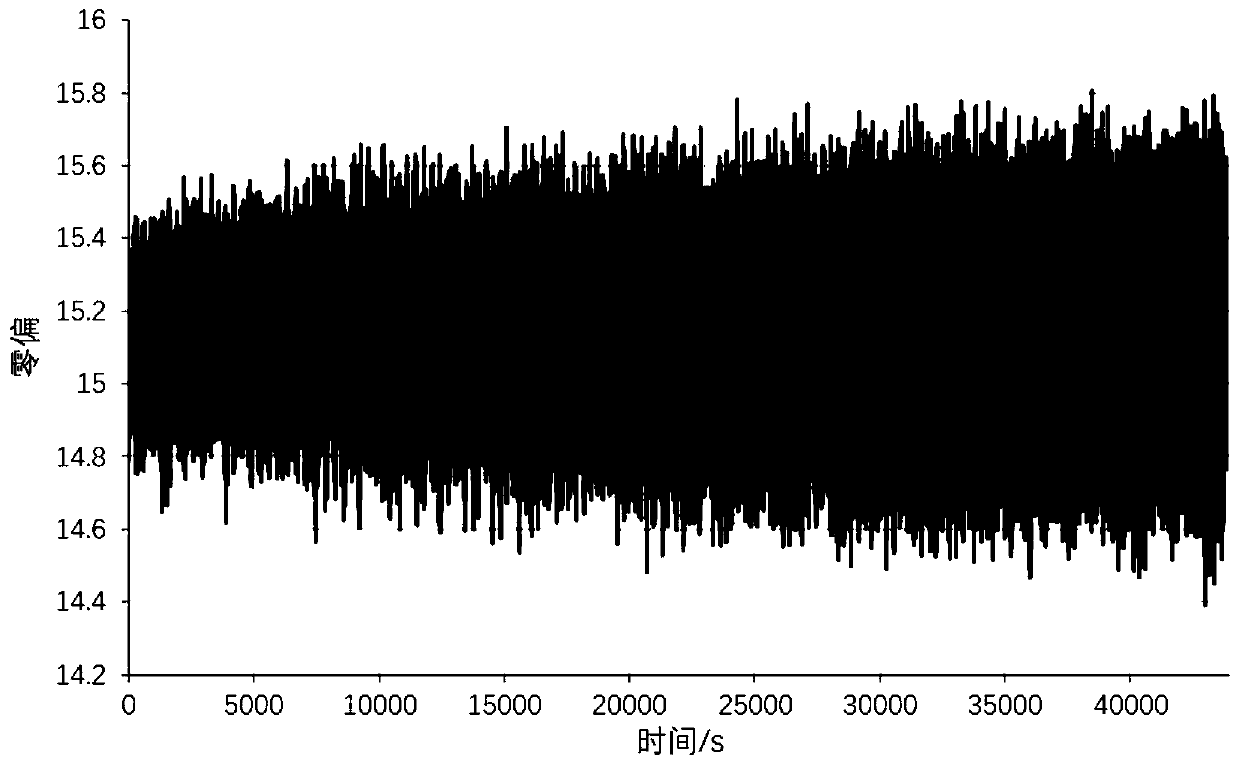

[0055] Step 1. Place the ring laser on the turntable, test the output pulse number of the ring laser at rest, perform data processing, and calculate the variance.

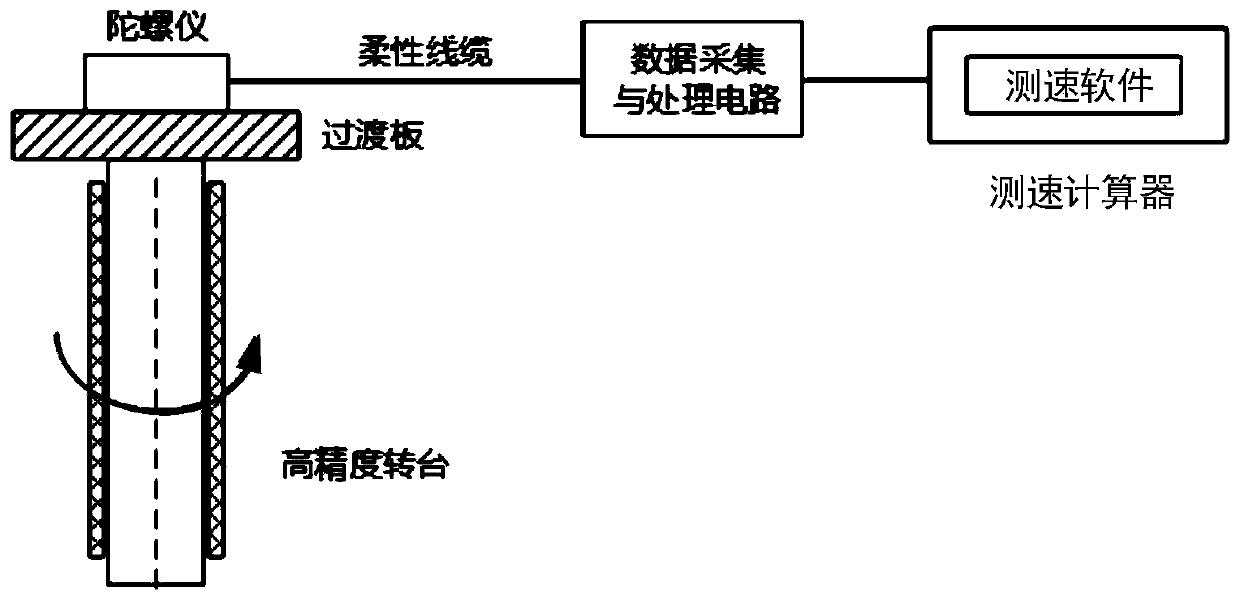

[0056] like figure 1 As shown, fix the ring laser at the center of the turntable. The axis of the laser should coincide with the axis of the turntable. After connecting the line, open the test software, start the ring laser to warm up for 30 minutes, and set the sampling interval by controlling the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com