A gas distribution device and a gas water heater using the device

A gas distribution device and gas technology, applied in the direction of valve devices, water heaters, fluid heaters, etc., can solve the problems of inflexible and convenient gas flow adjustment, high motor cost, high cost, etc., and achieve convenient, fast and flexible adjustment methods , improve work reliability, and be easy to process and produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

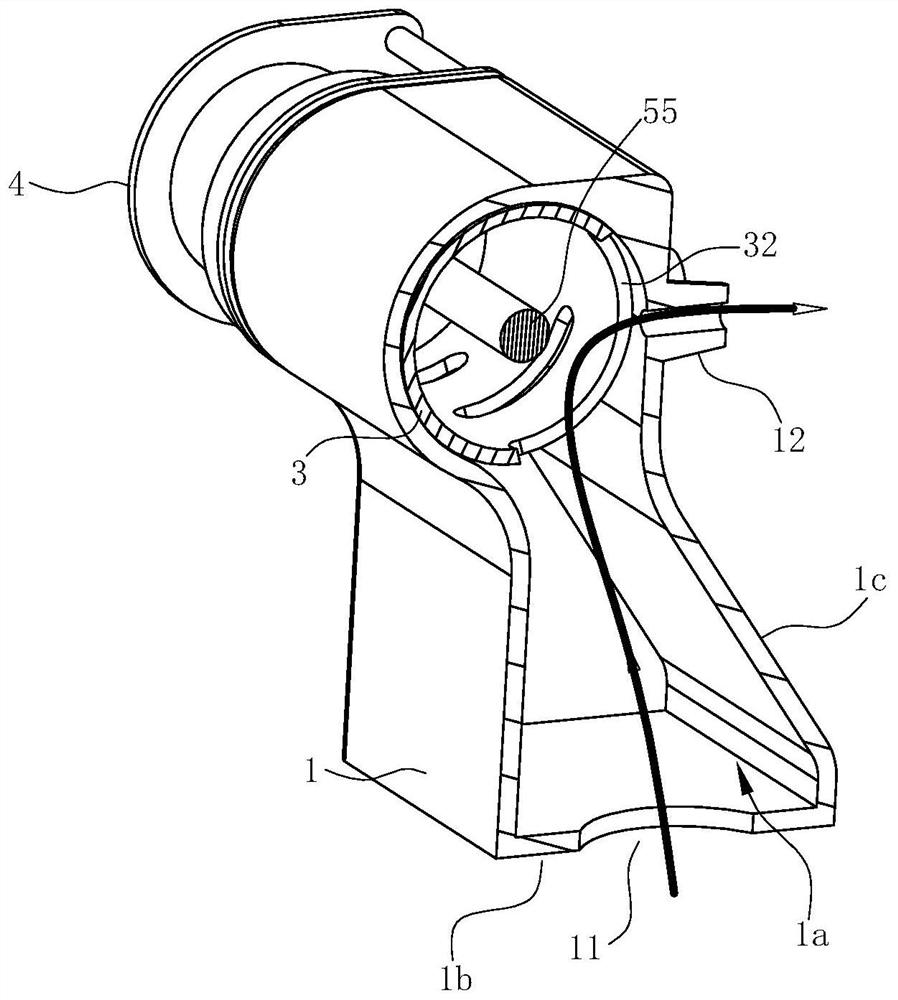

[0053] Such as Figure 13 As shown, the gas distribution device 10 of this preferred embodiment can be used in a gas water heater or a gas wall-hung boiler. This embodiment takes a gas water heater as an example. The gas water heater includes a burner 101, a gas distribution device 10 and a device for controlling the gas intake amount. Gas train 102.

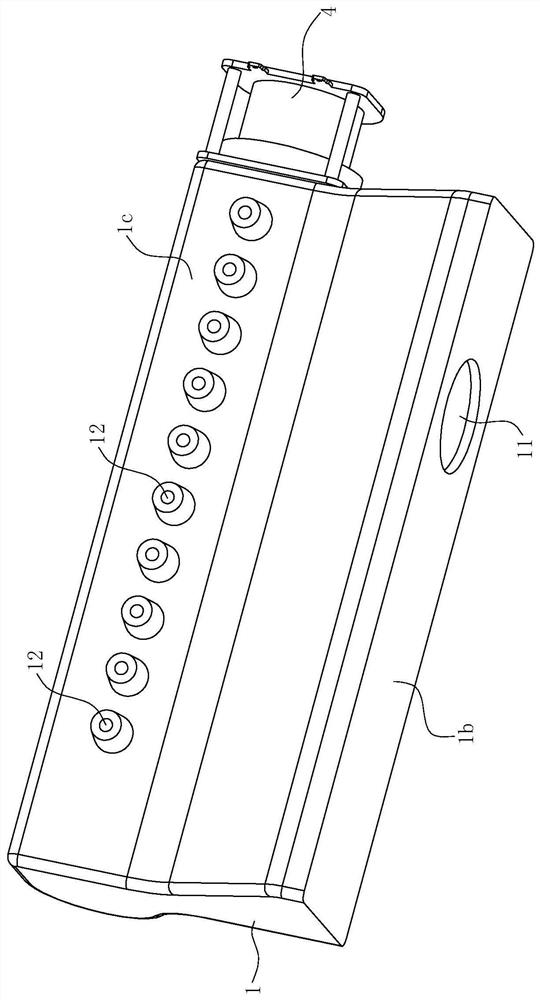

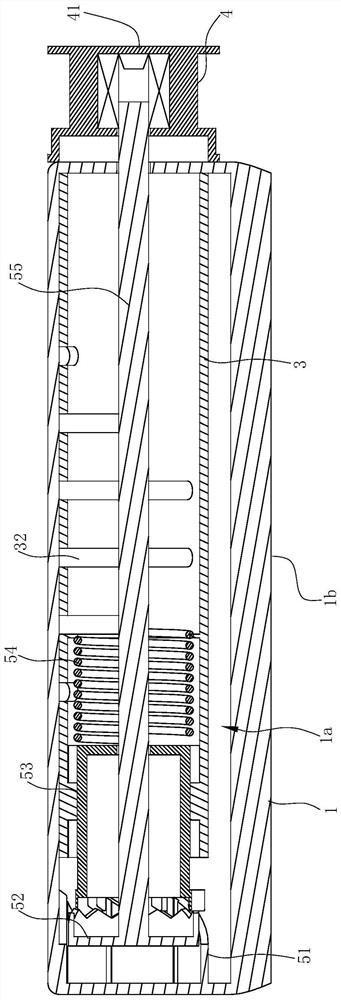

[0054] Such as Figure 1-13 As shown, the gas distributing device 10 includes a housing 1, a rotary drum 3 and a stepping drive mechanism. The housing 1 has a hollow inner chamber 1a, and a first side wall 1b of the housing 1 is provided with a first opening for gas to enter. An air inlet 11 , the gas valve group 102 communicates with the first air inlet 11 , of course there may be multiple first air inlets 11 . On the second side wall 1 c of the casing 1 , there are at least two nozzles 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com