Polycrystalline diamond compact drill bit and machining method thereof

A technology of polycrystalline diamond and composite disc drill bit, which is applied in the direction of drill bit, drilling equipment, earthwork drilling, etc. It can solve the problems of easy formation of mud balls, increase of drilling resistance, difficulty in core chip removal, etc., so as to prevent mud balls and quickly Effect of chip removal and prevention of chip accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

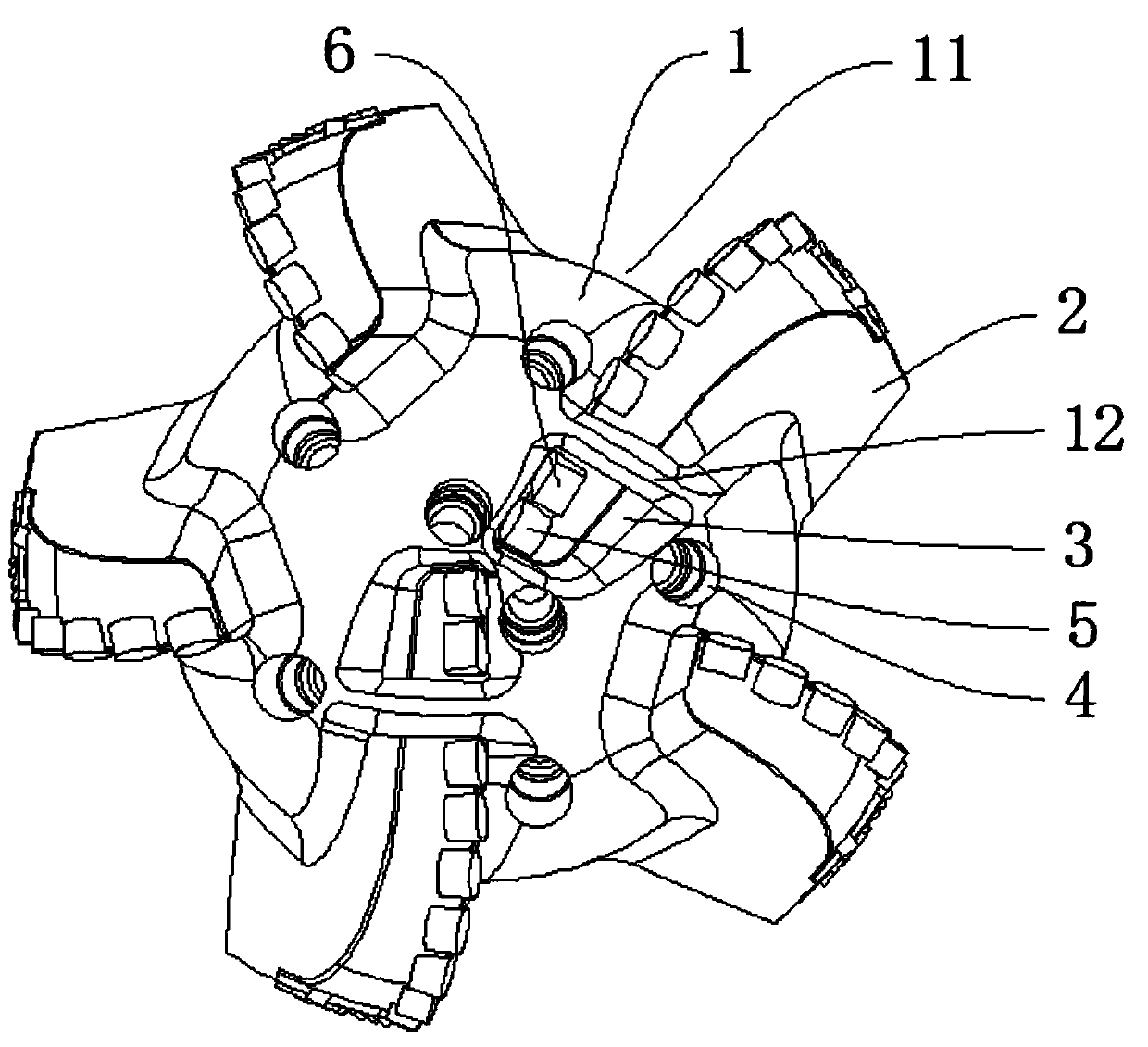

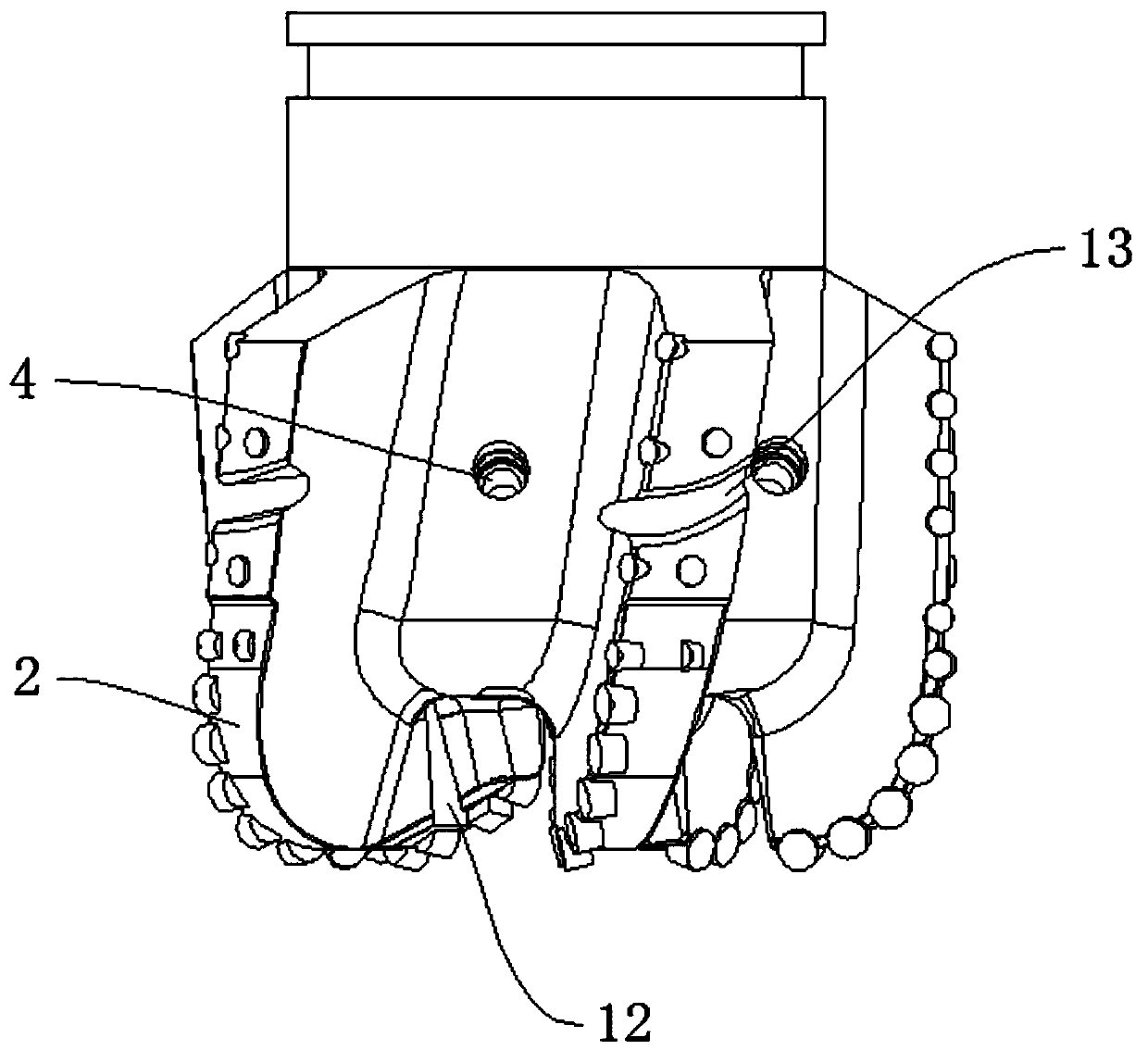

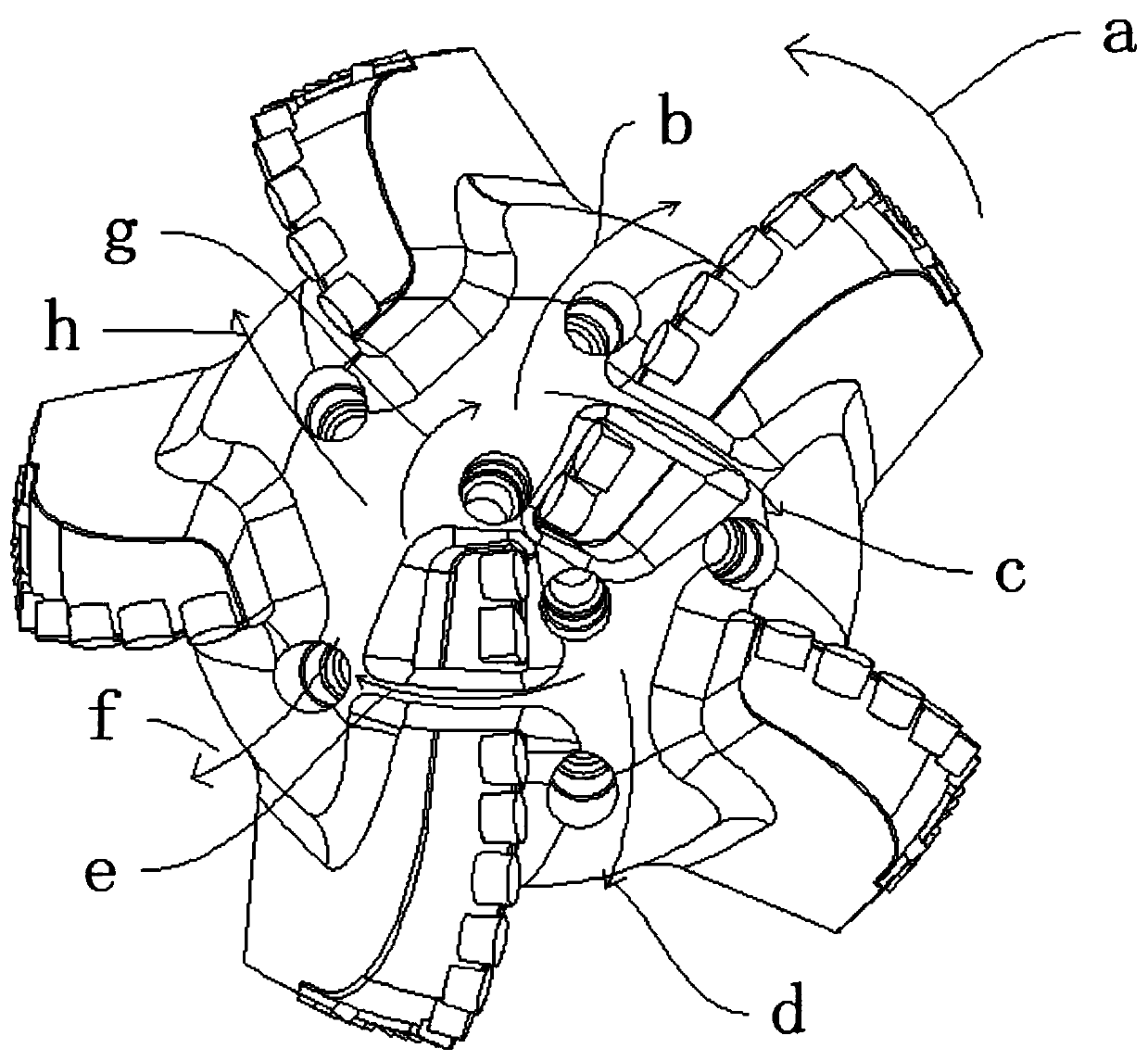

[0031] A polycrystalline diamond compact drill bit, comprising a body 1 and several main blades 2 arranged on the body 1, main chip removal grooves 11 are arranged between the main blades 2, and the front end of the main blades 2 extends to The inner cone of the body 1, the center of the body 1 is provided with an auxiliary blade 3, the auxiliary blade 3 is arranged inside the main blade 2 and forms an auxiliary row with the main blade 2 A chip flute 12, the two ends of the secondary chip flute 12 communicate with the adjacent main chip flute 11 respectively.

[0032] In the structure of the present application, since the center of the main body 1 is provided with an auxiliary blade 3, mud pockets are easily formed on the auxiliary blade 3. In the prior art, part of the front end of the main blade 2 extends to the center of the body 1. Part of the front end of the main blade 2 is easy to form a mud bag, but in the structure of the prior art, the debris in the center can only b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com