Tread compound with high wet slip resistance and low rolling resistance for tire and synthetic method of tread compound

A low rolling resistance, tire tread technology, applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve the problems of heating and energy loss of components, reduce rolling resistance, improve wet skid resistance, The effect of improving wet skid and rolling resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

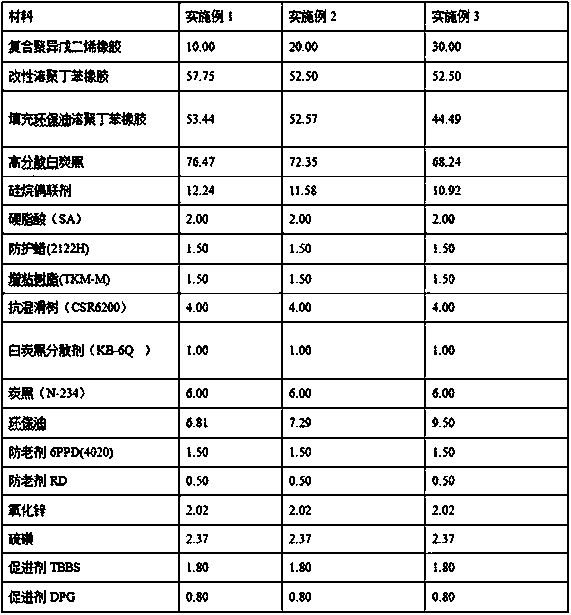

Examples

preparation example Construction

[0042] A kind of synthetic method of high anti-wet skid low rolling resistance tire tread compound, comprises the steps:

[0043] 1) Weigh each raw material according to parts by weight;

[0044] 2) One-stage mixing: add rubber, high-dispersion silica, carbon black, silane coupling agent, stearic acid, anti-aging agent, anti-slip resin, silica dispersant, environmental protection oil pressure into the denser according to the formula ratio Mix in the mill to obtain a section of rubber compound, the rotor speed is 55rpm, the wind pressure is 0.6MPa, put in rubber, the rubber is mixed for 10 minutes and the top bolt is lifted, the speed is reduced to 50rpm, and high-dispersion white carbon black, carbon black, silane coupling are put in agent, stearic acid, anti-aging agent, anti-slip resin, white carbon black dispersant, environmental protection oil pressure top bolt, the rubber is mixed to 120°C and lifted to the top bolt for cleaning, the speed is reduced to 40rpm, and the rubbe...

Embodiment 1~ Embodiment 3

[0053] Example 1~Example 3 Tire bench test performance (tire specification 155 / 70R13 75T):

[0054]

[0055] The index Tanδ0°C values of the wet skid resistance of the tread rubber listed in Examples 1-3 listed in the present invention are 0.443, 0.784, 0.878 respectively; the index Tanδ60°C value of the tread rubber rolling resistance listed in Examples 1-3 0.112, 0.031, 0.106 respectively;

[0056] The properties of the finished tires produced by using the tread rubber of the above-mentioned embodiments all reached or exceeded the national standard. The above are all preferred embodiments of the present invention, and through optimization, it is finally determined that Embodiment 3 is the first preferred embodiment of the present invention.

[0057] It can be seen from the table that the profile performance of the tire made by the present invention meets the national standard, has good grip, ensures the safety factor of wet driving, and has ultra-high wear resistance, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com