Microbial fertilizer for improving activity of functional microbes and preparation method of microbial fertilizer

A microbial fertilizer and a production method technology are applied in the field of microbial fertilizers for improving the activity of functional bacteria and the production field thereof, which can solve the problems of short shelf life of microbial fertilizers, poor survival effect of functional bacteria, etc. The effect of promoting the release of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

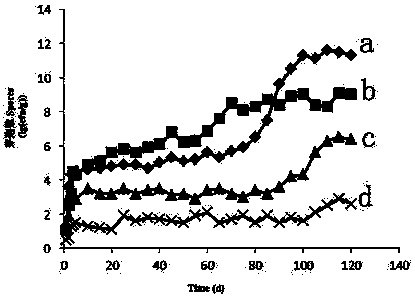

Image

Examples

Embodiment 1

[0027] A preparation method of a microbial fertilizer that improves the activity of functional bacteria, comprising the steps of:

[0028] Fertilizer decomposing: mix pig manure and wheat straw at a ratio of 2:1, totaling 10kg (sampling test, preliminary estimation: its hydrocarbon organic matter is 69.22wt%, nitrogen content rate is 3.16wt%; its carbon-nitrogen ratio is 30.5:1) Add 5g of Bacillus licheniformis species, stack evenly, control moisture content to about 55%; porosity to 50%; pH to 7.0; temperature to 37°C, ferment for 14 days under ventilated conditions, and turn over in 3 days Pile once, ventilate, and finally get well-rotted organic fertilizer.

[0029] High-temperature sterilization: Air-dry the decomposed organic fertilizer naturally, and then place it in an oven at 80°C to remove most of the miscellaneous bacteria at high temperature.

[0030]Secondary fermentation: After cooling down to normal temperature, take 5kg of air-dried and decomposed organic ferti...

Embodiment 2

[0033] On the basis of Example 1, the concentrated monosodium glutamate waste liquid in the secondary fermentation was replaced with a mixed nutritional supplement of 12g beef extract, 38g peptone and 10g sodium chloride.

[0034] All the other steps are identical with embodiment 1; Wherein, the deviation of control parameters such as above-mentioned humidity, porosity, temperature, pH and embodiment 1 is less than 1.2%.

Embodiment 3

[0036] On the basis of Example 1, the mixed strains in the secondary fermentation were replaced with 10 g of Bacillus subtilis single strains.

[0037] All the other steps are identical with embodiment 1; Wherein, the deviation of control parameters such as above-mentioned humidity, porosity, temperature, pH and embodiment 1 is less than 1.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com