Pretreatment method and equipment for physical and chemical deamination of garbage leachate

A landfill leachate and pretreatment technology, which is applied in the treatment of polluted groundwater/leachate, chemical instruments and methods, degassed water/sewage treatment, etc., can solve the problem of high energy consumption of ammonia nitrogen, avoid secondary pollution, The effect of reducing processing cost and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

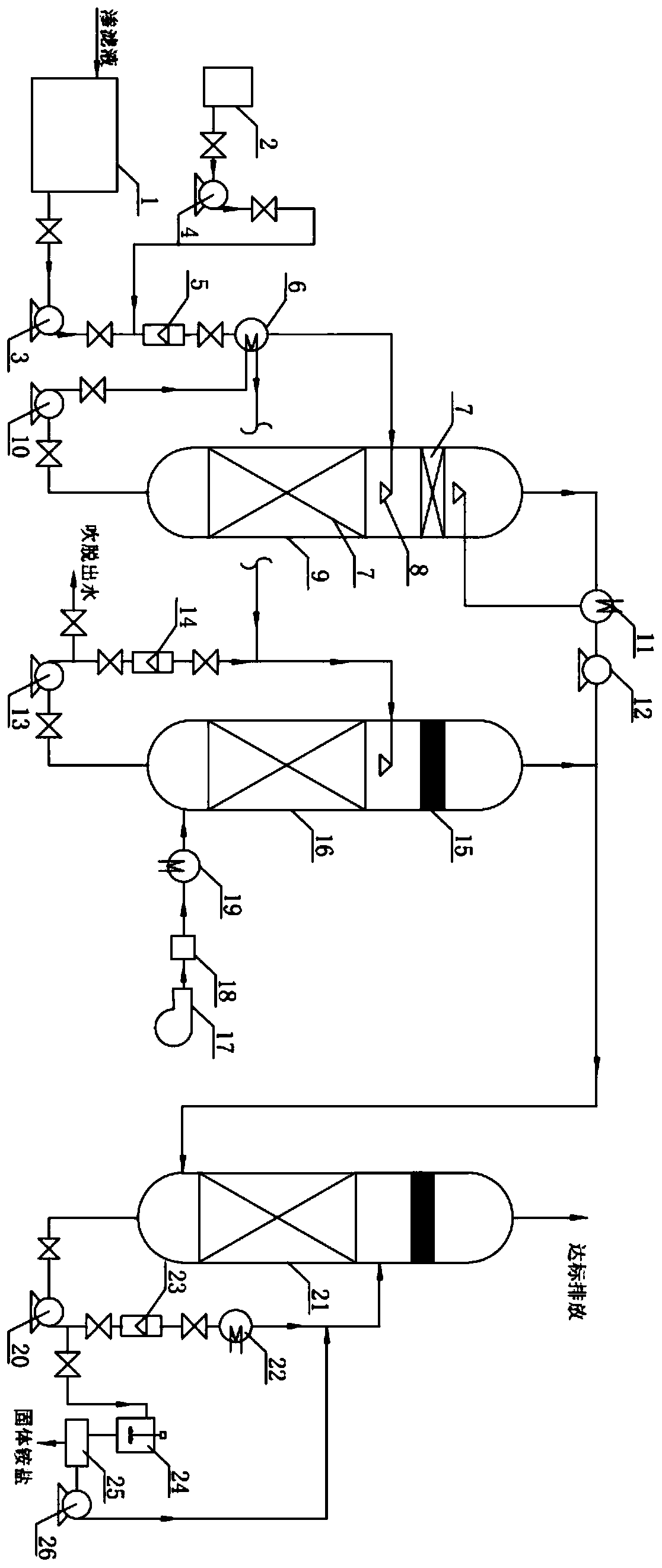

[0046] figure 1 The equipment diagram for the high-efficiency physical and chemical deamination pretreatment of landfill leachate provided for this example, as figure 1 As shown, the equipment specifically includes:

[0047] (1) Pretreatment unit: comprising a connected waste water regulating settling tank 1 and a carbonate decomposition aid storage tank 2, the waste water regulating settling tank 1 is provided with a feed pump 3, and the carbonate decomposition aid storage tank 2 is composed of The dosing pump 4 is regulated, and the effluent of the wastewater regulating sedimentation tank enters the negative pressure evaporation unit through the flow meter 5 and the wastewater heat exchanger 6 .

[0048] (2) Negative pressure evaporation unit: comprising a negative pressure evaporation tower 9, its upper water inlet is connected to the wastewater regulating sedimentation tank 1, the inside is equipped with a filler 7, a distributor 8 is provided, a vacuum pump 12 is install...

Embodiment 2

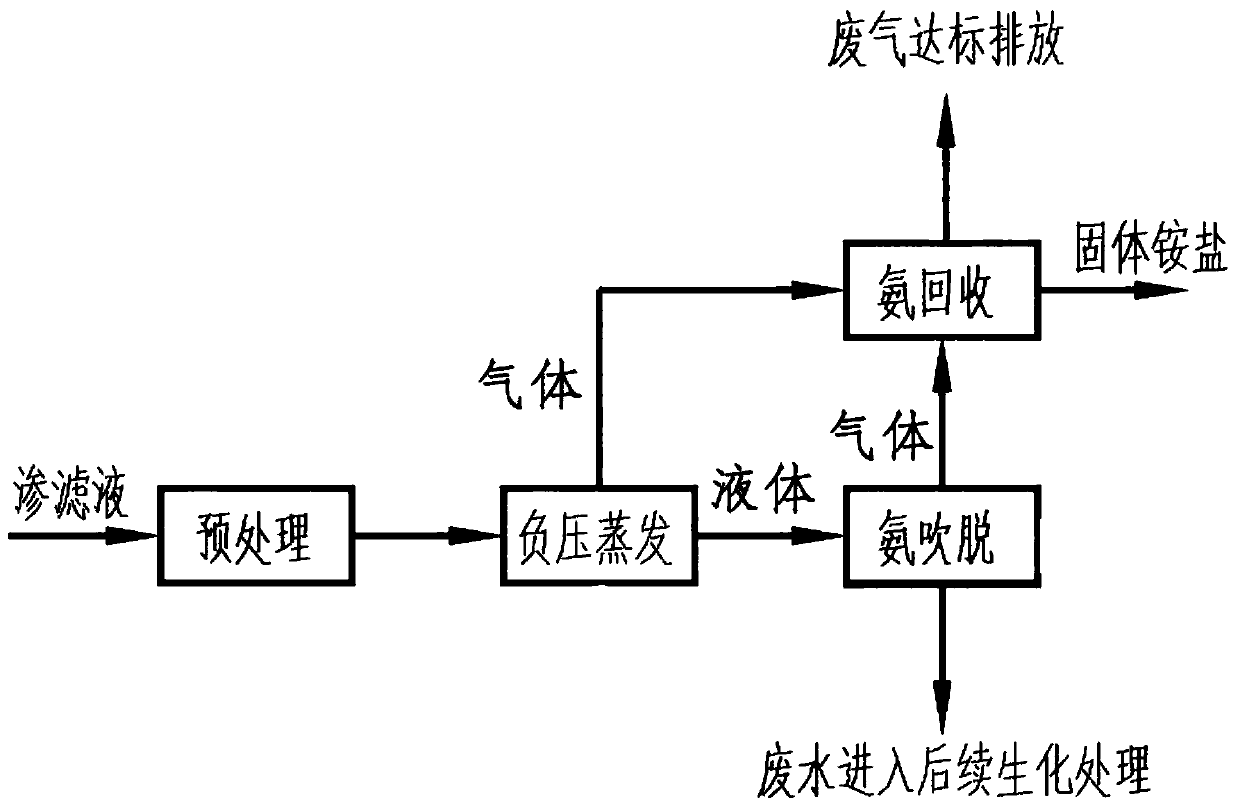

[0053] figure 2 The process flow diagram of the high-efficiency physical and chemical deamination pretreatment of landfill leachate provided for the embodiment, as figure 2 As shown, the technological process mainly includes the following steps:

[0054] (1) Transport the landfill leachate to the pretreatment unit to realize solid-liquid separation, and add carbonate decomposition aids to the supernatant;

[0055] (2) Transport the supernatant of the pretreatment unit to a negative pressure evaporation unit, perform negative pressure evaporation until the pH of the supernatant is greater than 9, and transport the liquid evaporated under negative pressure to the ammonia stripping unit.

[0056] (3) The gas after the ammonia stripping and the gas after the negative pressure evaporation are sent to the ammonia recovery unit.

[0057] Specifically, combined with figure 1 The equipment diagram of high-efficiency physical and chemical deamination pretreatment of landfill leacha...

Embodiment 3

[0063] A landfill leachate wastewater, composition and concentration: NH 3 -N is 1500~2000mg / L, pH is 8~8.5, utilizes the equipment of the present invention to carry out ammonia nitrogen removal pretreatment steps as follows:

[0064] 1) Pump the landfill leachate into the wastewater regulating sedimentation tank for sedimentation, add carbonate decomposition additives to the supernatant, the addition amount is 10ppm, and then exchange heat with the effluent of the negative pressure evaporation tower to about 60°C.

[0065] 2) The pretreated wastewater enters the upper part of the evaporation tower and is evenly distributed by the liquid distributor. The heating temperature at the bottom of the tower is about 80°C; turn on the vacuum pump to vacuum the evaporation tower under negative pressure. The operating pressure is -0.06MPa, containing carbonate decomposed CO 2 The evaporated tail gas of ammonia and ammonia enters the bottom of the ammonia absorption tower after passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com