Folding-arm telescopic rotary crane

A crane and arm-type technology, applied in the field of knuckle-boom telescopic slewing cranes, can solve the problems of increased hoisting range, insufficient hoisting range of slewing cranes, etc. Flexible arm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

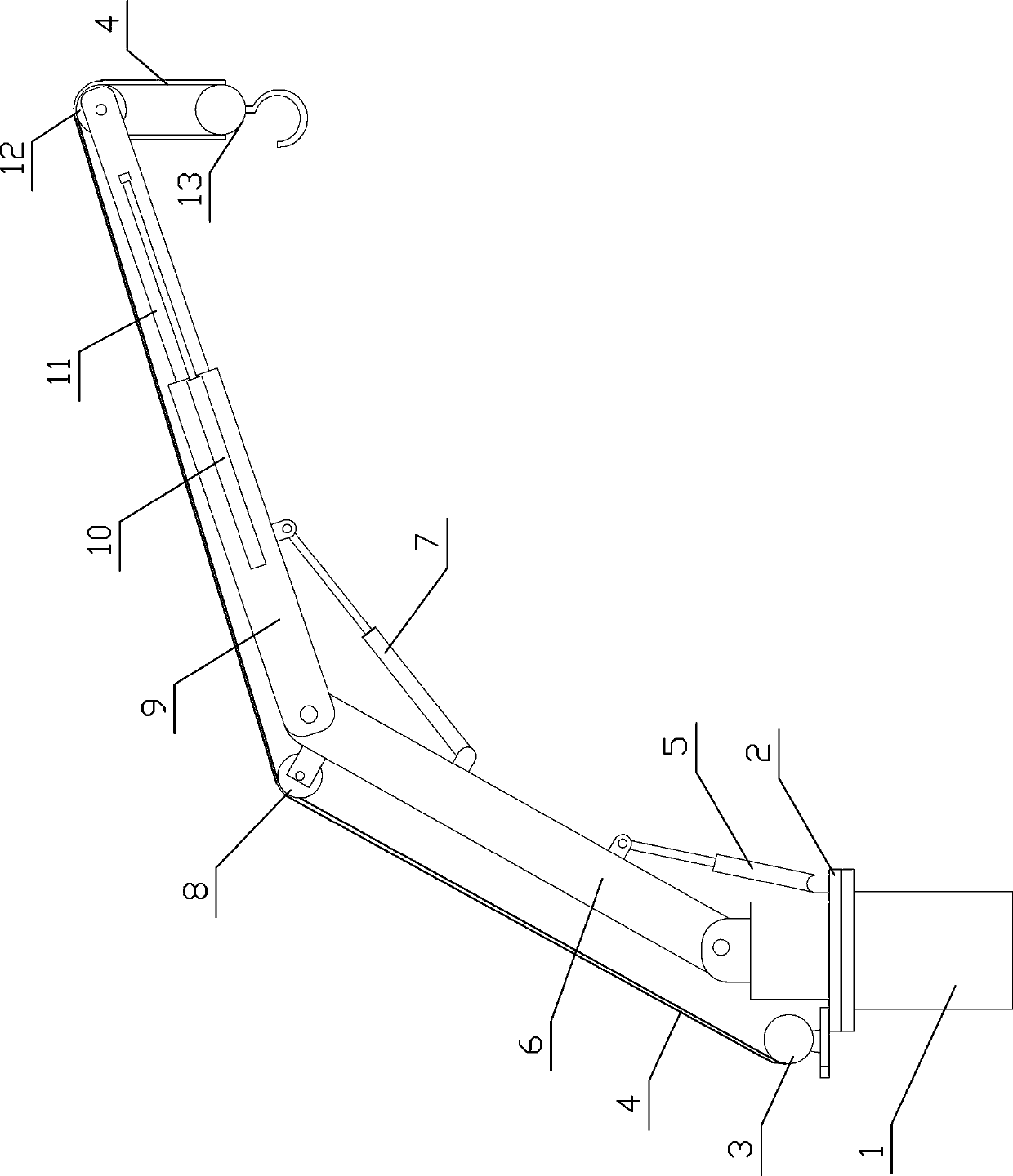

[0008] see figure 1 , this embodiment includes a base 1, a revolving base is installed on the base 1, a boom is hinged on the top of the revolving base, a pulley 12 is hinged on the top of the boom, a hook 13 is installed on the pulley 12 through a suspension rope 4, and a driving crane is installed on the revolving base. The motor 3 for lifting and lowering the hook 13, the slewing base includes the slewing platform 2 at the bottom, and the boom includes the first-stage boom 6, and the oil cylinder A5 is hinged on the turret 2, and the piston rod of the oil cylinder A5 is connected to the bottom surface of the first-stage boom 6. Hinged, the top of the primary boom 6 is hinged with the secondary boom 9, the bottom surface of the primary boom 6 is also hinged with an oil cylinder B7, the piston rod of the oil cylinder B7 is hinged with the bottom surface of the secondary boom 9, and the secondary boom 9 is sleeved with The third-stage boom 11, the side of the second-stage boom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com