Horizontal ring cutter numerical control cutting device

A ring-knife and cutting technology, applied in metal processing and other directions, can solve problems such as the inability to ensure the accuracy of the sponge rotating position, affecting the shape of the sponge, and the offset of the number of cutting layers, so as to reduce manual labor, ensure smooth progress, and ensure The effect of rotary cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

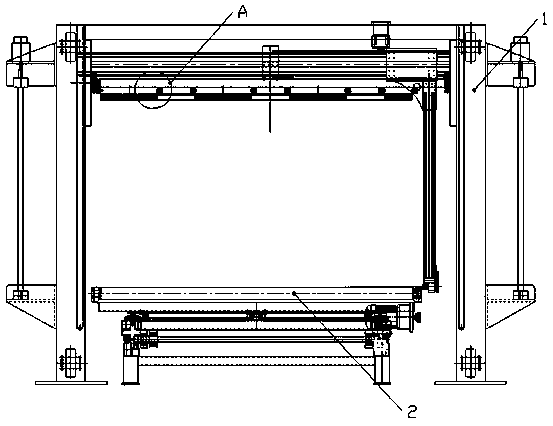

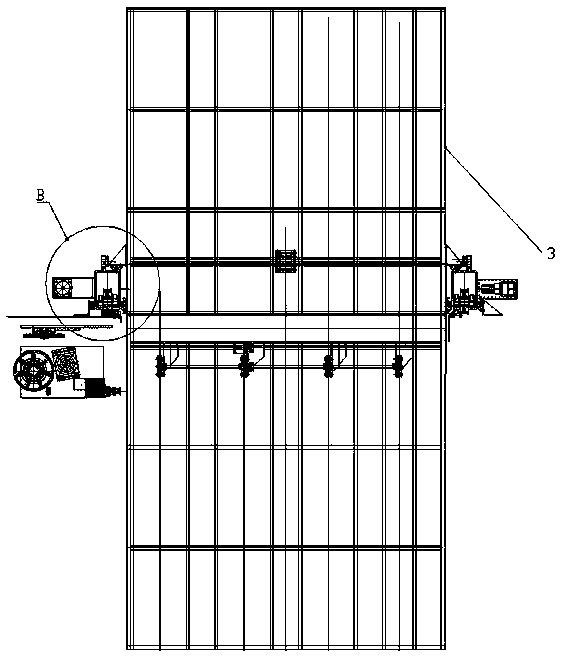

[0036] Such as Figure 1-Figure 7 A kind of horizontal ring knife numerical control cutting device shown, comprises

[0037] A delivery mechanism 2, the delivery mechanism 2 includes a delivery support 21, a work platform is installed on the delivery support 21, the work platform is composed of a rotating platform 22 and a fixed platform 23 distributed up and down, and the rotating platform 22 is provided with a conveyor belt or Conveyor roller 24.

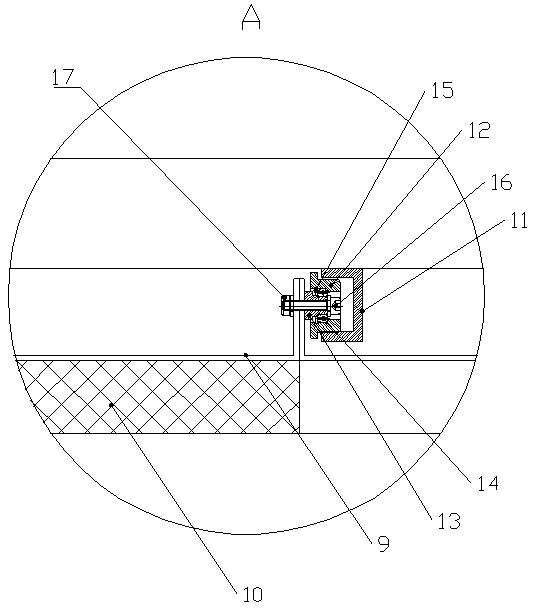

[0038] The rotating platform 22 is driven by a rotating mechanism to rotate 360° with the center of the fixed platform 23 as the rotation point. The rotating mechanism is: a slewing bearing 25 is arranged between the rotating platform 22 and the fixed platform 23, and the outer ring of the slewing bearing 25 and the The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com