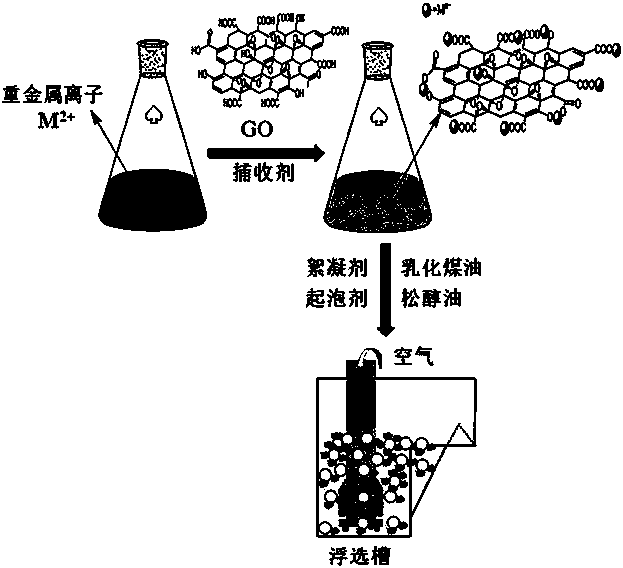

Method for treating heavy metal wastewater through ion flotation of nano collecting agent

A technology for collectors and heavy metals, which is applied in the fields of flotation water/sewage treatment, flotation, chemical instruments and methods, etc., can solve the problems of high cost, large consumption, removal rate of heavy metal ions in secondary pollution, etc., and achieves easy operation. , Small footprint, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for treating lead ions in heavy metal wastewater by ion flotation with nano-collectors, the specific process is as follows:

[0030] Add 250mL of lead ion solution with a concentration of 10ppm into an ion flotation device with a flotation cell of 250mL, adjust the pH of the solution to 4.0, and add a certain amount of graphene oxide as a nano-collector to control the concentration of graphene oxide in the mixed solution. Concentration is 0.5mg / L, stir at 1800rpm for 5min; then, add flocculant emulsified kerosene with D90 of 0.1μm, the amount of emulsified kerosene added is 20mg / L, keep stirring for 3min; then, add foaming agent pine at 10mg / L Alcohol oil, continue to stir for 3 minutes; finally, flotation for 5 minutes under the aeration rate of 0.6L / min, the turbidity of the tail liquid is 3.9 NTU, and the residual concentration of lead ions in the tail liquid is 0.2 mg / L, reaching the industrial standard. Wastewater discharge standards.

Embodiment 2

[0032] A nano-collector ion flotation method for treating copper ions in heavy metal wastewater, the specific process is as follows:

[0033]Add 250mL of copper ion solution with a concentration of 500ppm into an ion flotation device with a flotation cell of 250mL, adjust the pH of the solution to 6.5, and add a certain amount of graphene oxide as a nano-collector to control the concentration of graphene oxide in the mixed solution. Concentration is 1.0mg / L, stir at 1800rpm for 5min; then, add flocculant emulsified kerosene with D90 of 2.0μm, the amount of emulsified kerosene added is 100mg / L, keep stirring for 3min; Foaming agent pine alcohol oil, continue to stir for 3 minutes; Finally, flotation for 7 minutes under the aeration rate of 1.1L / min, the turbidity of the tail liquid recorded is 2.2 NTU, and the residual concentration of copper ions in the tail liquid is 0.8mg / L, It has reached the discharge standard of industrial wastewater.

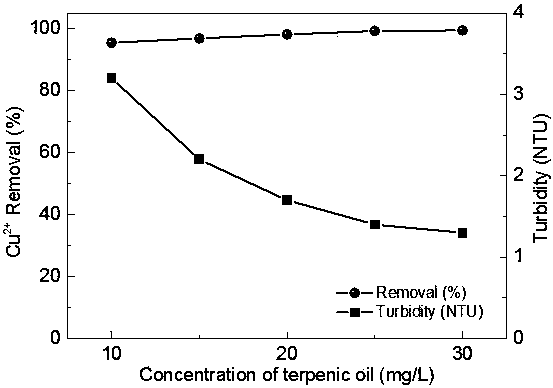

[0034] Under the condition that ot...

Embodiment 3

[0036] A nano-collector ion flotation method for treating zinc ions in heavy metal wastewater, the specific process is as follows:

[0037] Add 250mL of zinc ion solution with a concentration of 2000ppm into an ion flotation device with a flotation cell of 250mL, adjust the pH of the solution to 7.0, and add a certain amount of graphene oxide as a nano-collector to control the concentration of graphene oxide in the mixed solution. The concentration is 2.0mg / L, stirring at 1800rpm for 5min; then, add flocculant emulsified kerosene with a D90 of 0.1μm, the amount of emulsified kerosene added is 20mg / L, and keep stirring for 3min; Foaming agent pine alcohol oil, continue to stir for 3min; Finally, flotation 10min under 1.5L / min, the turbidity that records tail liquid is 1.3NTU, and the residual concentration of zinc ion in tail liquid is 0.4mg / L, It has reached the discharge standard of industrial wastewater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com