Full-automatic feed grinding device for livestock raising and using method

A fully automatic, grinding technology, applied in feed, application, grain processing and other directions, can solve the problems of poor grinding effect, high waste rate, low degree of automation, etc., to prevent the feed grinding particles from being too large, easy to operate, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

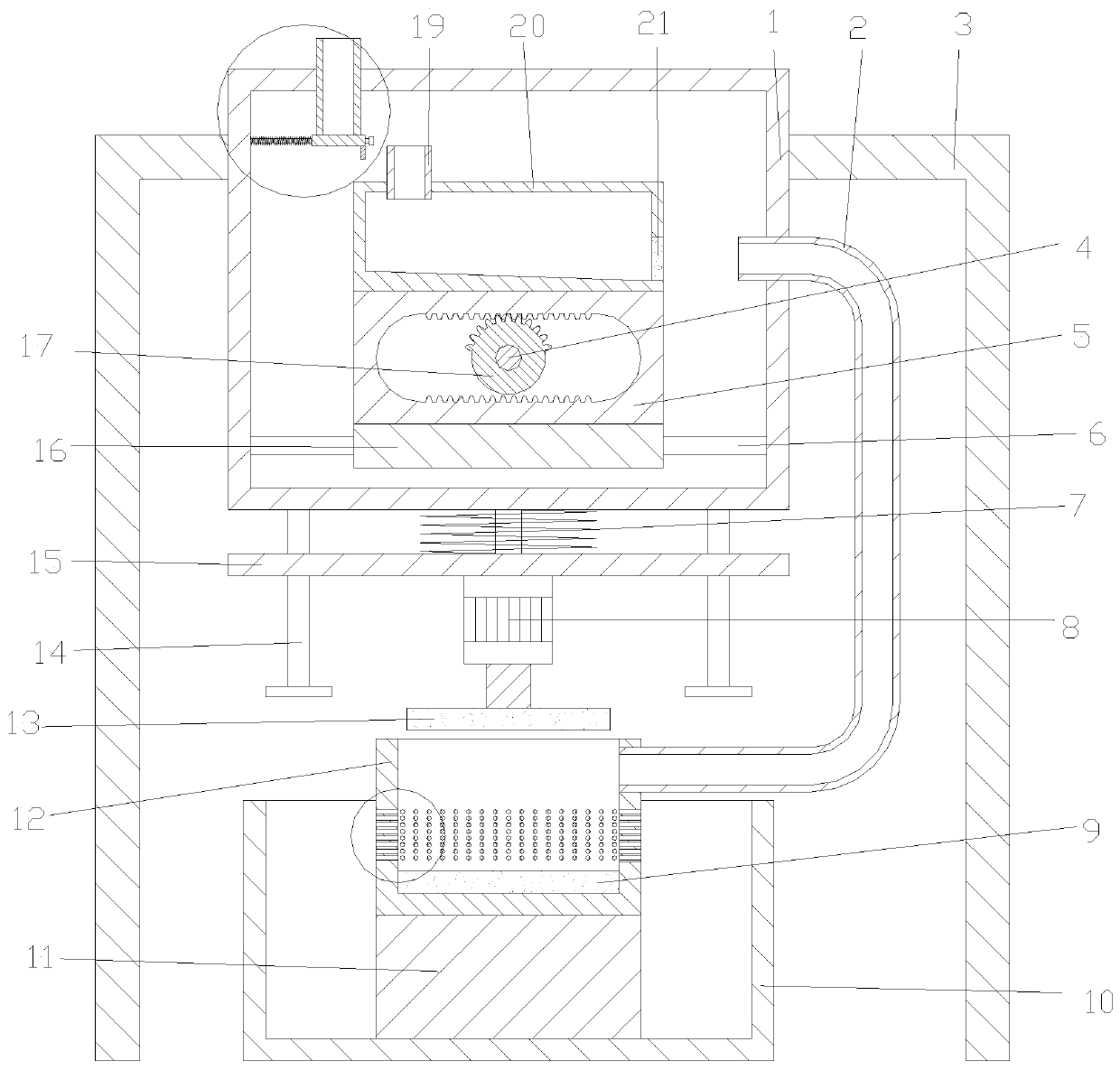

[0020] The present invention will be further described below in conjunction with accompanying drawing:

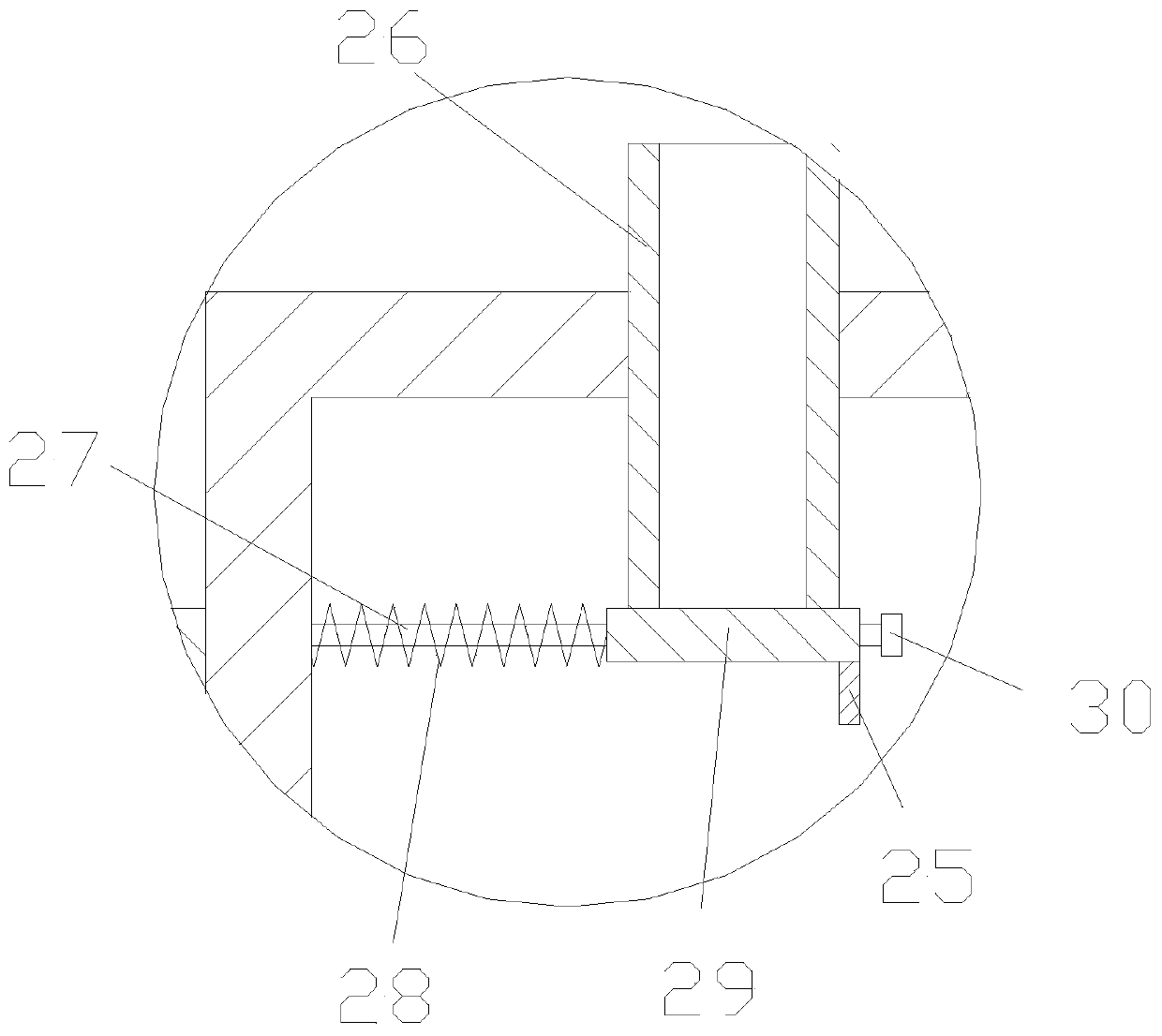

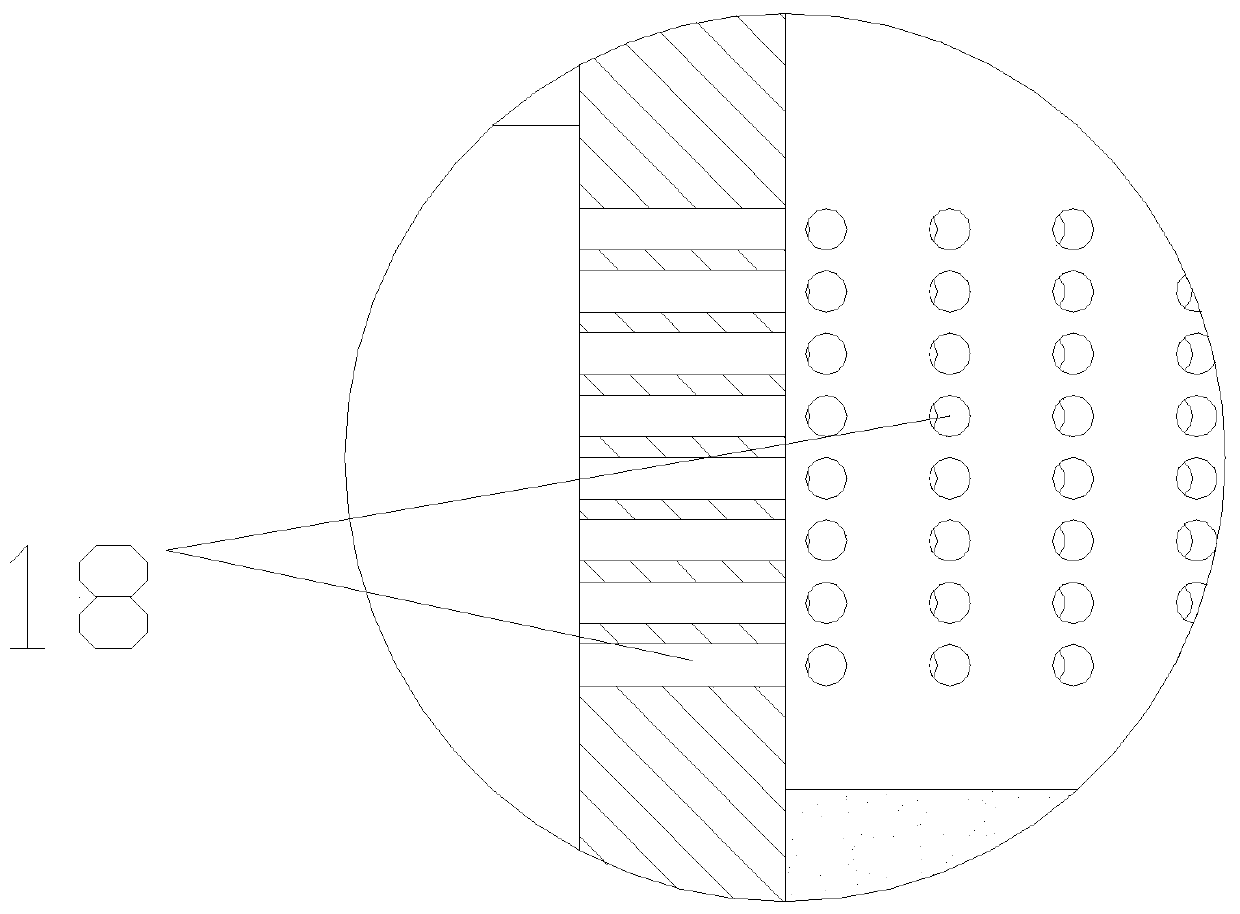

[0021] Refer to attached figure 1 , 2 : In the present embodiment, this automatic feed grinding device for animal husbandry includes a casing 1, and the upper part of the inside of the casing 1 is provided with a fixed material box 20, and the left half of the inner wall of the fixed material box 20 top is fixed. A feed pipe 19 communicating with the outside world is installed, the bottom inner wall of the fixed material box 20 is a slope from high to low from left to right, and the bottom of the inner wall at the right end of the fixed material box 20 is provided with a check valve 21 connected to the outside world, so The bottom of the fixed feed box 20 is fixedly equipped with a return-shaped block 5, and the bottom of the return-shaped block 5 is provided with double sliding rods-6 that are fixedly connected with the inner walls of the left and right ends of the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com