Safe and energy-saving cooking utensil

A cooking utensil and safety technology, applied in the field of safe and energy-saving cooking utensils, can solve the problems of large amount of steam, rising water temperature, pollution of the kitchen environment, etc., and achieve the effect of good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

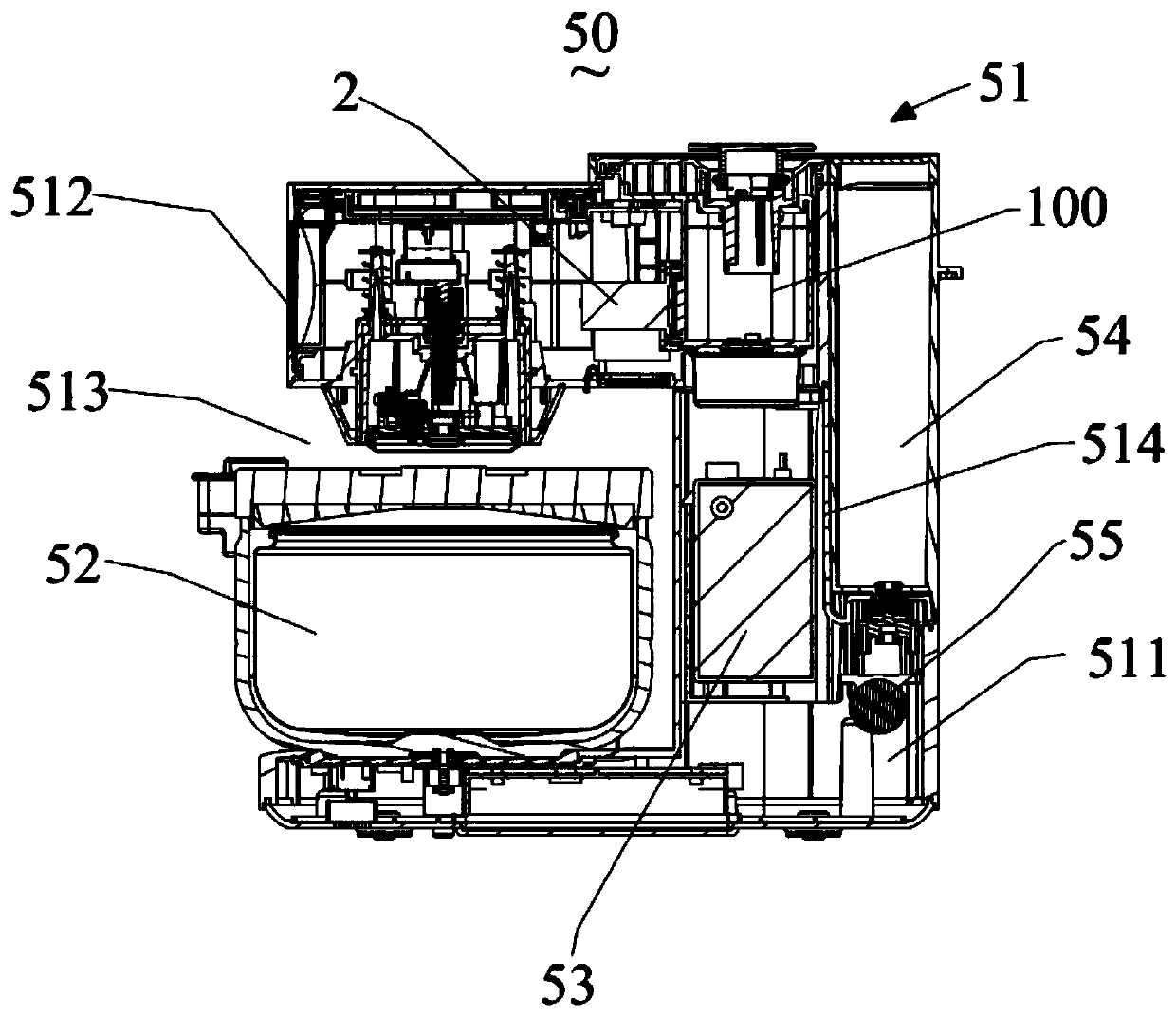

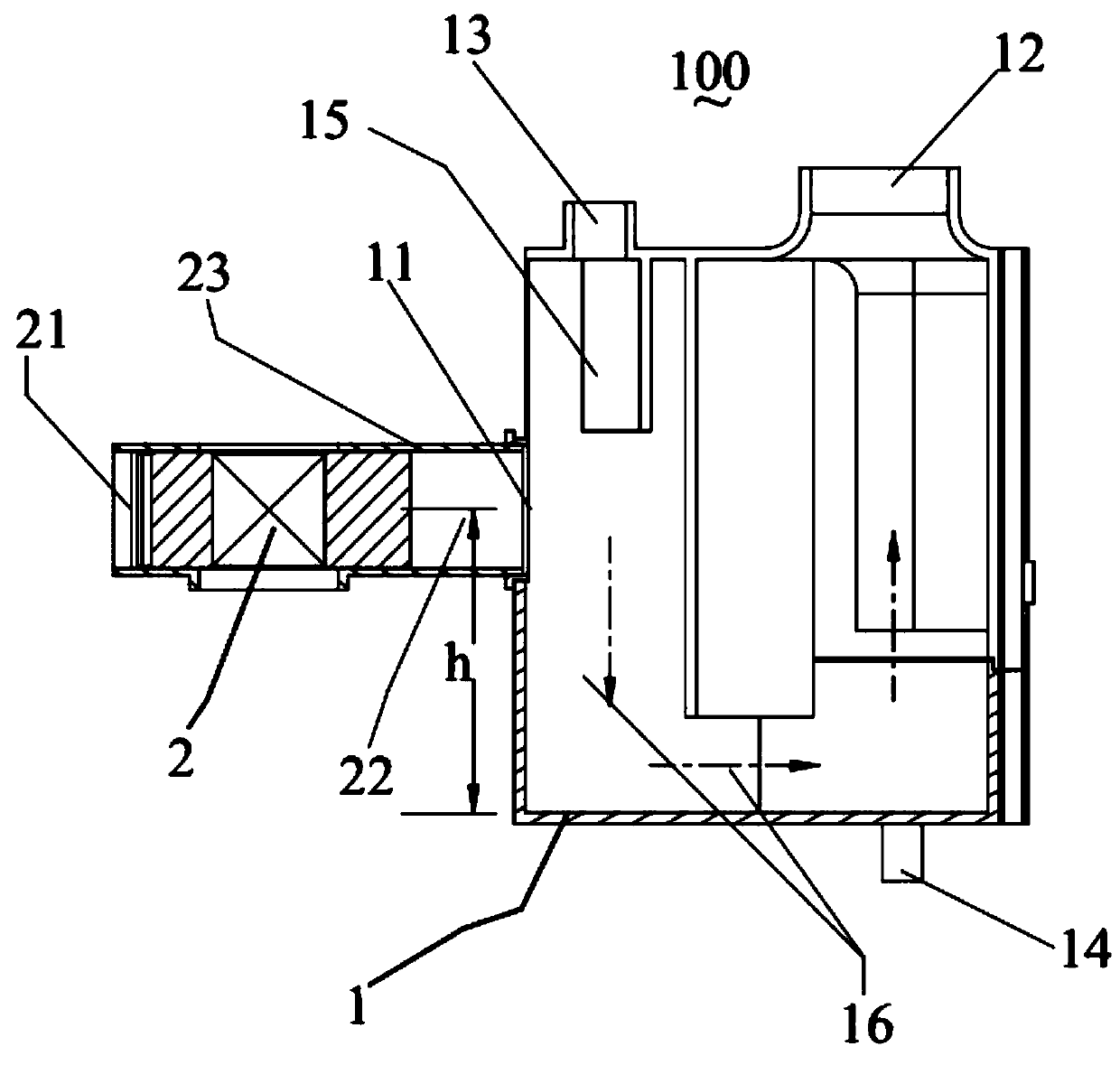

[0034] see figure 1 , figure 2 As shown, the first embodiment of a safe and energy-saving cooking appliance 50 according to the present invention includes a main body 51, a pot body 52, and a steam generator 53 arranged in the body. The pot body 52 is placed in the body 51. The steam generator 53 communicates with the inside of the pot body to supply steam to heat the food in the pot body. A steam condensing device 100 connected to the pot body to condense steam is also provided in the body. The steam condensing device includes a cooling mixing chamber 1, an accelerated steam cooling The fan 2 of the cooling mixing chamber 1 is provided with an air inlet 11, an exhaust port 12, a first steam inlet 13, and a drain port 14. The first steam inlet 13 guides steam into the cooling mixing chamber 1, and the drain port 14 is arranged in the cooling mixing chamber. Bottom of chamber 1. The fan 2 is provided with an air inlet 21 and an air outlet 22. The cold air blown out by the ai...

Embodiment 2

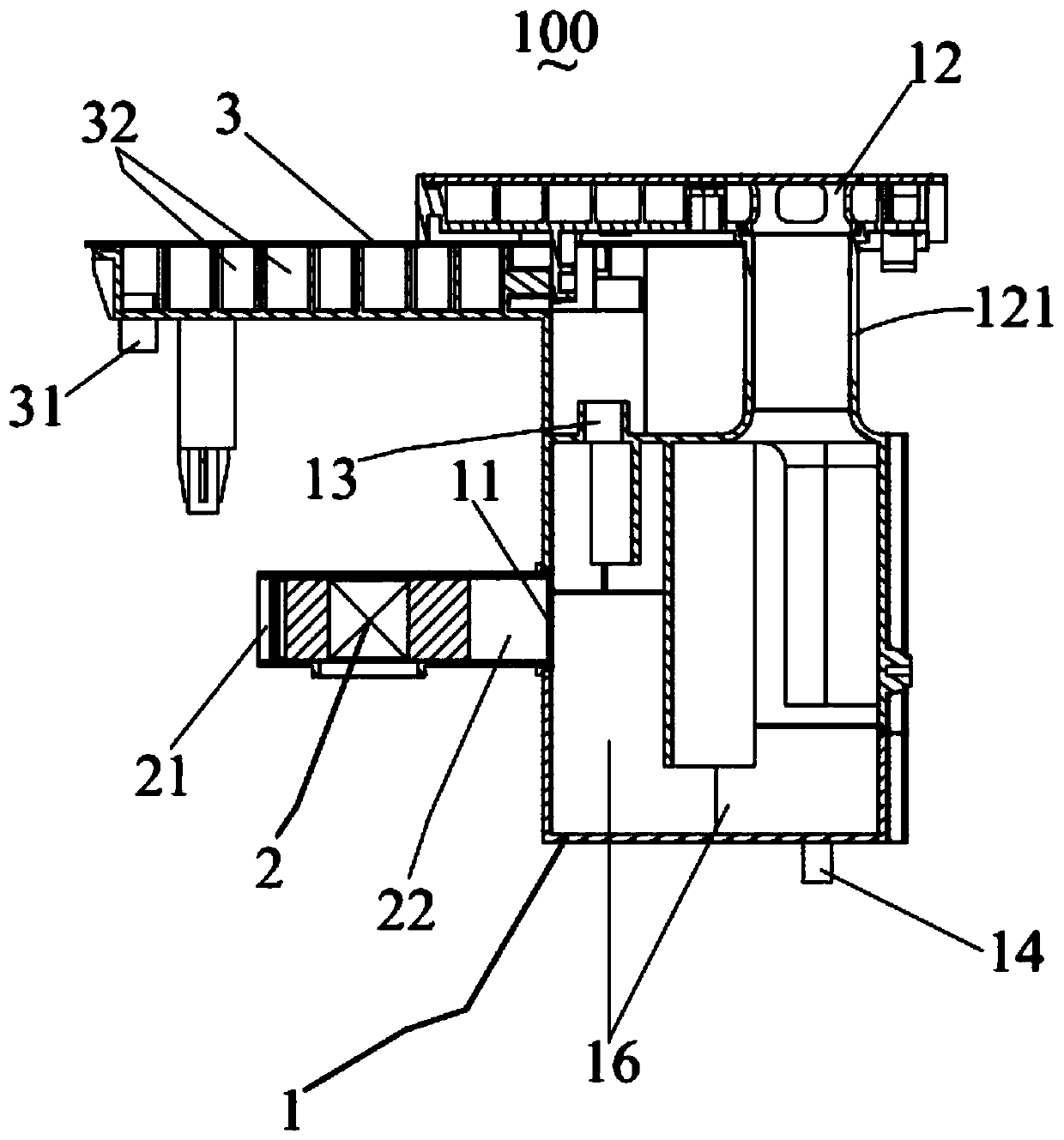

[0059] see image 3 As shown, the second embodiment of the present invention adds a cooling buffer chamber 3 on the basis of Embodiment 1, the cooling buffer chamber is arranged at the front end of the first steam inlet 13, and the cooling buffer chamber is provided with a second steam inlet 31, To introduce steam into the cooling buffer chamber 3 , the first steam inlet 13 communicates with the cooling buffer chamber 3 to introduce the steam in the cooling buffer chamber into the cooling mixing chamber 1 .

[0060] In this embodiment, the cooling buffer chamber 3 is arranged at the front end of the first steam inlet 13 to perform preliminary cooling and buffer reserve for the steam entering the cooling mixing chamber, so as to avoid the injection of cold air into the cooling mixing chamber and affect the front end. Steam heating or front-end heating effect.

[0061] As an improved embodiment, the cooling and buffer chamber 3 is also provided with a drain hole (not shown in t...

Embodiment 3

[0069] see Figure 4 As shown, the fourth embodiment of the present invention is improved on the basis of the first embodiment. The cooling mixing chamber 1 includes a first mixing part 10 formed by a steam introduction pipe 4, and a second mixing part 20. The first steam The inlet is the boundary between the steam introduction pipe and the first mixing part. That is to say, a third steam introduction port 41 is provided at the front end of the steam introduction pipeline for steam introduction flow, and the rear end of the steam introduction pipeline 4 forms the first mixing part 10 of the cooling mixing chamber, and the mixing, exhaust, structures such as drainage.

[0070] As a preferred embodiment, the shape of the second mixing part is consistent with the first embodiment. The air inlet is arranged in the first mixing part 10 . In this embodiment, the steam leading pipe is used to form a part of the cooling mixing chamber, which enlarges the effective cooling path of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com