Laminating method of PCB and buffer layer

A kind of PCB circuit board, buffer layer technology, applied in the direction of printed circuit, multilayer circuit manufacturing, printed circuit manufacturing, etc., can solve the problems of cleaning and quality, kraft paper sticking to the bottom and cover of the steel plate and hot press, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

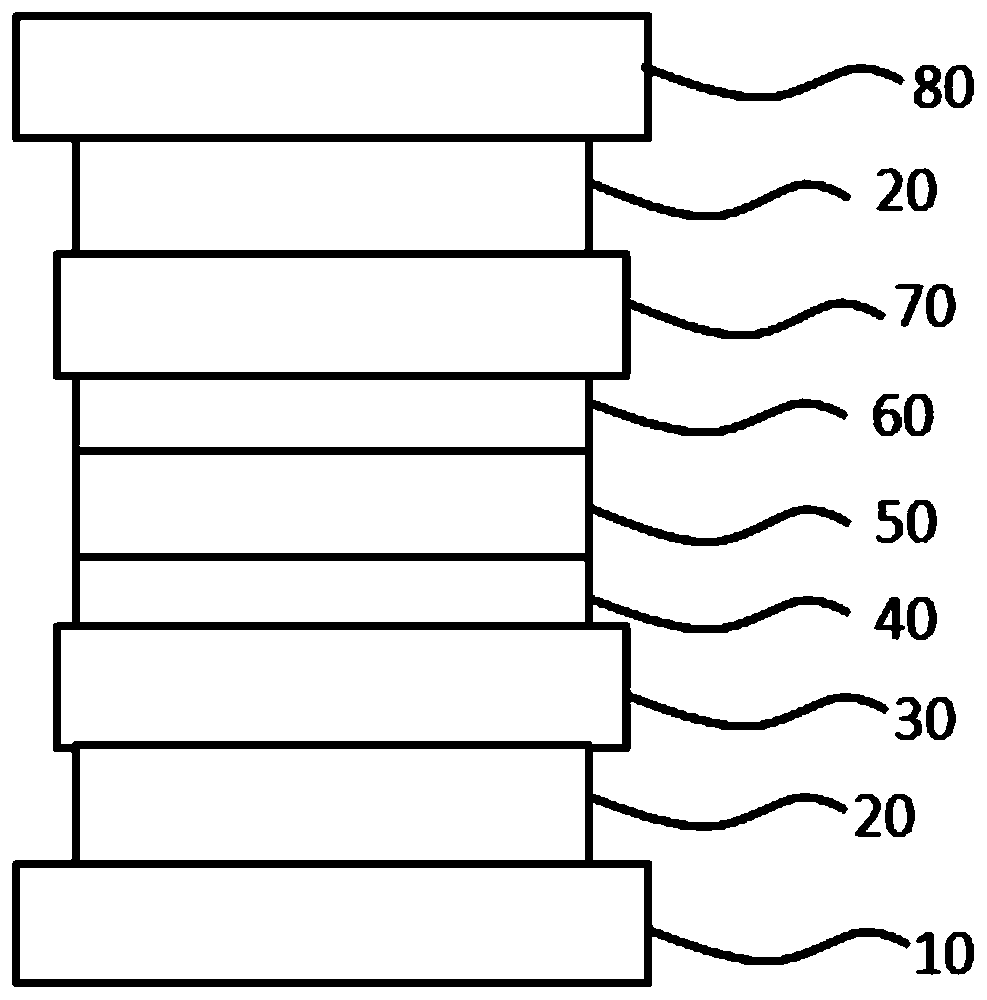

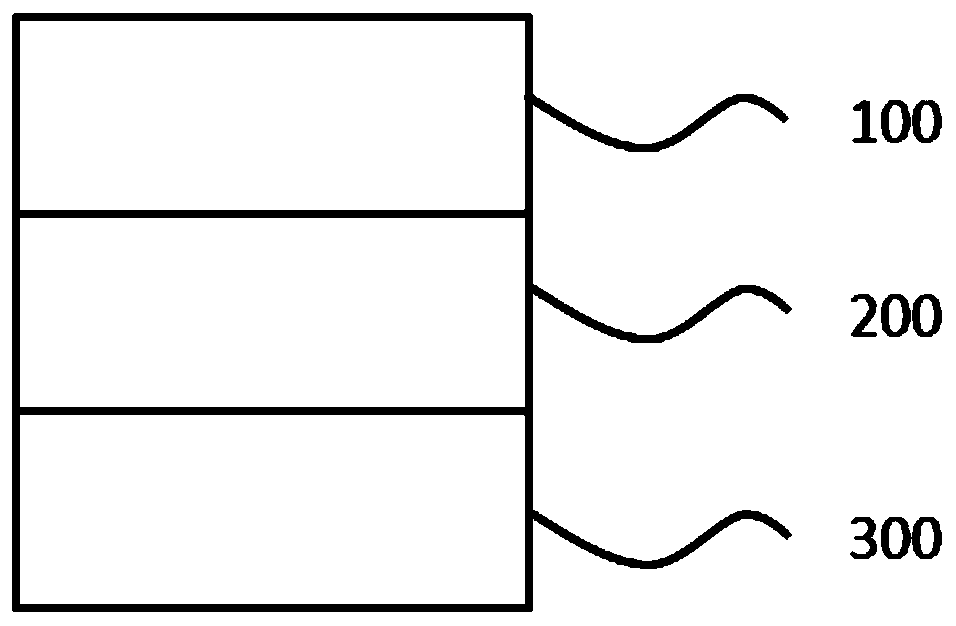

[0038] A method for pressing a PCB circuit board, comprising the following steps:

[0039] Browning: Oxidize the surface of the inner circuit board to enhance the bonding force between the inner circuit board and the prepreg.

[0040] In this example, the browning solution used in the browning process is MacDermid Multibond MP, the browning speed: 3.4±0.3m / min, and the microetching amount: 1.5μm.

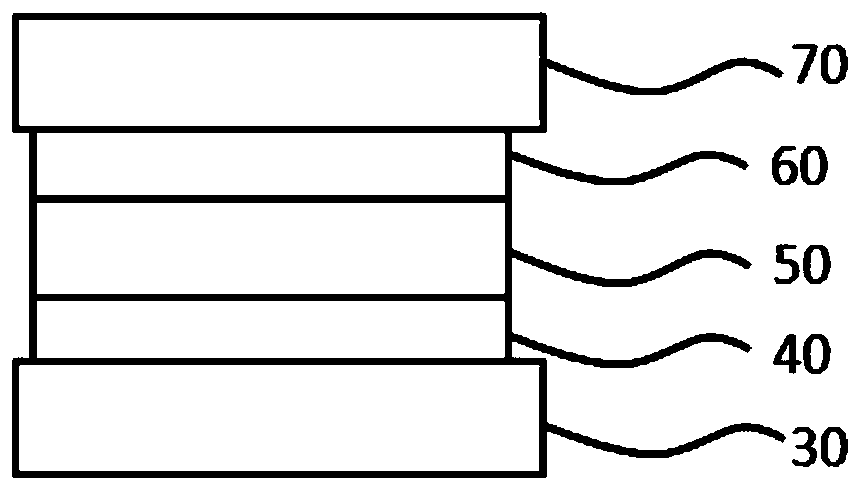

[0041] Pre-stacking: using a prepreg to laminate two or more browned inner circuit boards. When the prepreg is pressed, it can tightly combine the inner layer circuit board and the outer layer copper foil.

[0042] Understandably, after pre-stacking, both surfaces of the inner layer circuit board are pasted with prepregs. According to the production instructions, different types of prepregs can be selected for lamination.

[0043] Fusion: After laminating two or more inner-layer circuit boards after browning treatment with the prepreg, a fusion operation is performed to fix multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com