A contact state recognition method for robot assembly based on gwa-svm

A contact state and identification method technology, applied in machine learning and robot control, using the contact state identification field of industrial robot assembly parts, can solve the problem of low classification accuracy of industrial robot parts assembly force data, and achieve good convergence accuracy and fast convergence. Accurate classification of speed and contact state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

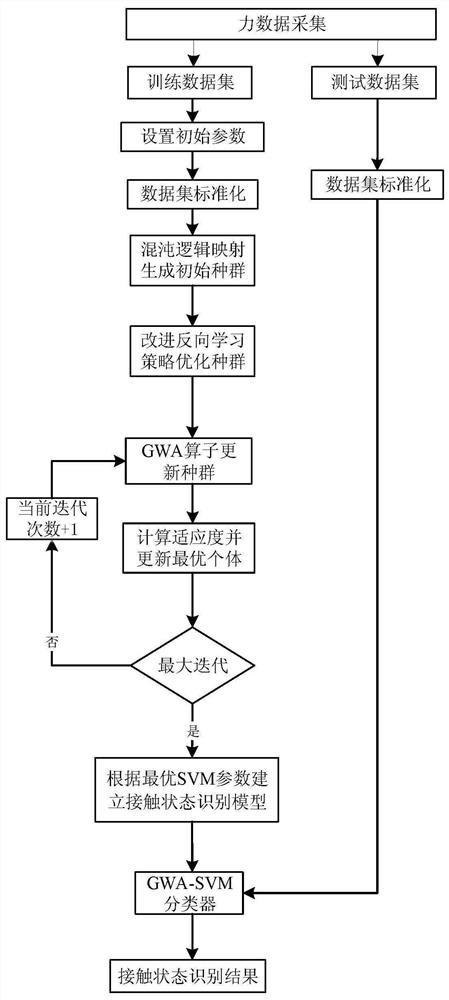

[0040] refer to Figure 1 ~ Figure 3 , a contact state recognition method for robot assembly based on GWA-SVM, comprising the following steps:

[0041] Step 1: Use the Mitsubishi industrial robot RV-2F to assemble the parts, collect multiple sets of force data during the assembly process through the six-dimensional force sensor 4F-FS001-W200, and establish a training data set {X1 , L 1} with the test dataset {X 2 , L 2}. where X 1 ,X 2 is the six-dimensional force data X=(f x ,f y ,f z ,m x ,m y ,m z ), f x ,f y ,f z Respectively force data along the x, y, z axis directions, m x ,m y ,m z are the torque data around the x, y, and z axes, respectively. L 1 , L 2 for respectively with X 1 ,X 2 The corresponding contact state, that is, the category to which the data belongs, the training data X 1 It is divided into 6 categories.

[0042] Step 2: Set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com