A manufacturing method for liquid crystal screen blue light component detection and analysis equipment and its manufacturing equipment

A technology for analyzing equipment and manufacturing methods, applied in optical instrument testing, optics, measuring devices, etc., can solve the problems of many detection parameters, small detection range, large detection field of view, etc., achieve high real-time detection, improve production quality, Detecting effects with a large field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

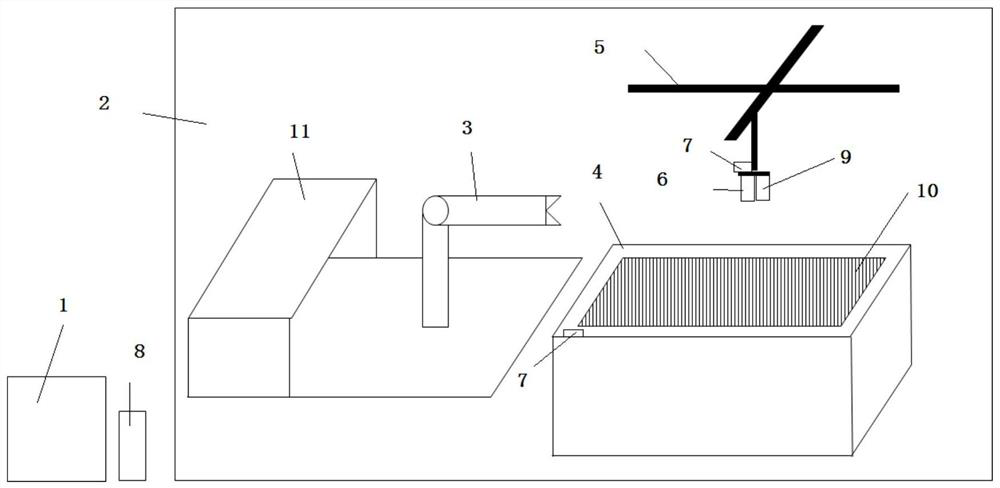

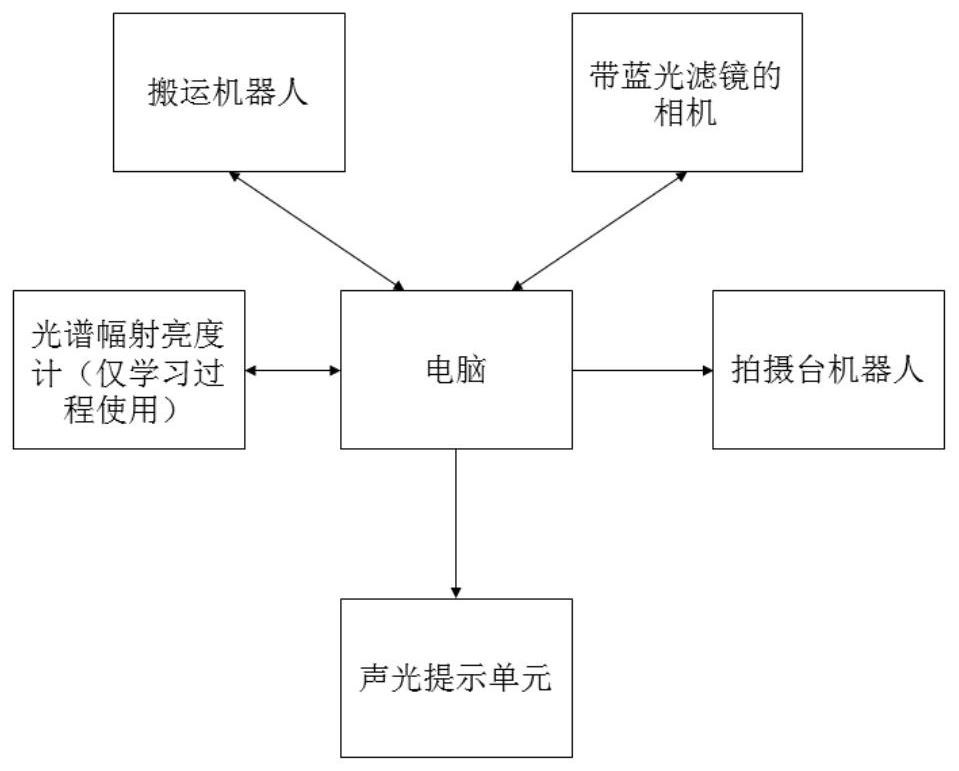

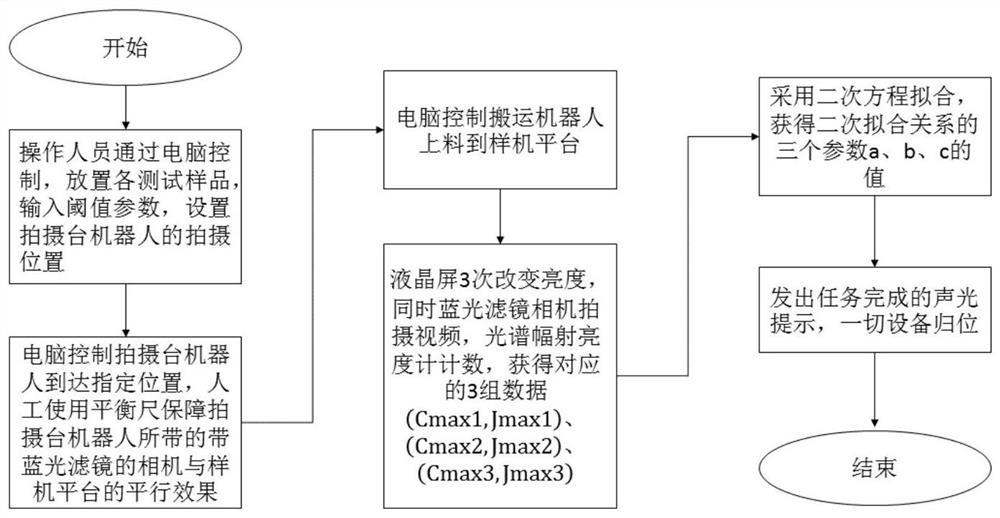

[0029] The following will be combined with the accompanying drawings figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the technical solution of the present invention will be described in detail.

[0030] Based on the existing machine vision and electronic technologies, the present invention proposes a blue light component detection and analysis device for liquid crystal screens and a manufacturing method thereof, which are used to detect the spatial uniformity, Time stability, maximum value and other parameters.

[0031] Aiming at the problem that the existing spectral radiance meter is expensive, the present invention proposes a manufacturing method for liquid crystal screen blue light component detection and analysis equipment, which only requires a spectral radiance meter to be calibrated and corrected during the manufacturing process, and the Obtaining multiple sets is simple in structure and easy to use. Low-cost blue light detection and analysis equipment....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com