Linkage system for electricity consumption and exhaust gas emission amount of exhaust gas purification equipment and application method thereof

A technology of exhaust gas purification and linkage system, which is applied in the directions of simultaneously indicating the values of multiple variables, measuring devices, complex mathematical operations, etc., which can solve the problems of electricity consumption, exhaust emission and occupation without enterprise environmental protection facilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

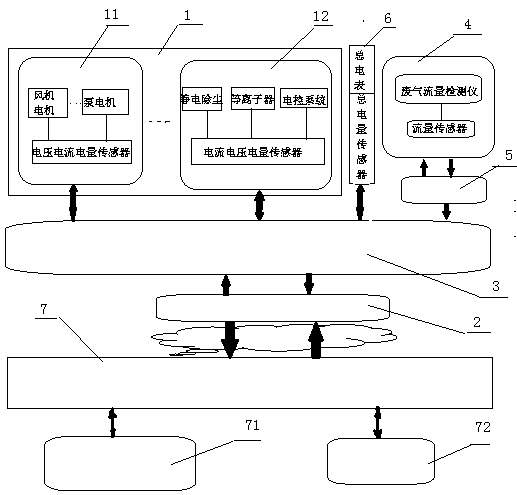

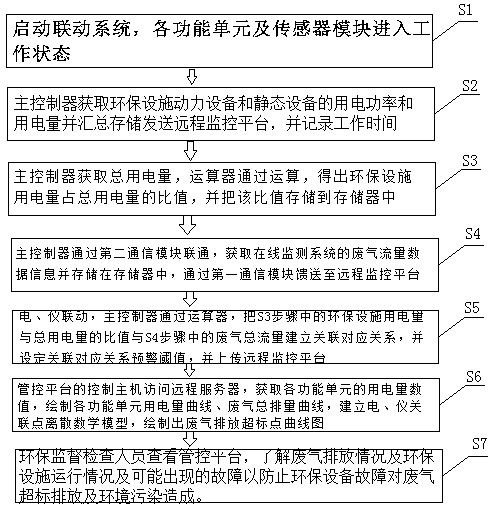

[0024] The following will be combined with figure 1 and figure 2 The embodiments of the technical solution of the present invention are described in detail. The following examples are only used to illustrate the technical solution of the present invention more clearly, so they are only examples, and should not be used to limit the protection scope of the present invention.

[0025] A linkage system of electricity consumption and exhaust gas emission of exhaust gas purification equipment, comprising: environmental protection equipment operation detection unit 1, first communication unit 2, main controller 3, exhaust gas online monitoring unit 4, second communication unit 5, production total Electricity detection unit 6, management and control platform 7; described management and control platform 7 includes a control host 71 and a monitor 72 for monitoring the operation of environmental protection equipment, and the control host 71 is connected to the first communication modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com