Method for stably controlling product moisture content for pneumatic drying system

A technology of airflow drying and stable control, applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of easy agglomeration of products, difficult to store, affecting the yield and efficiency of factories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

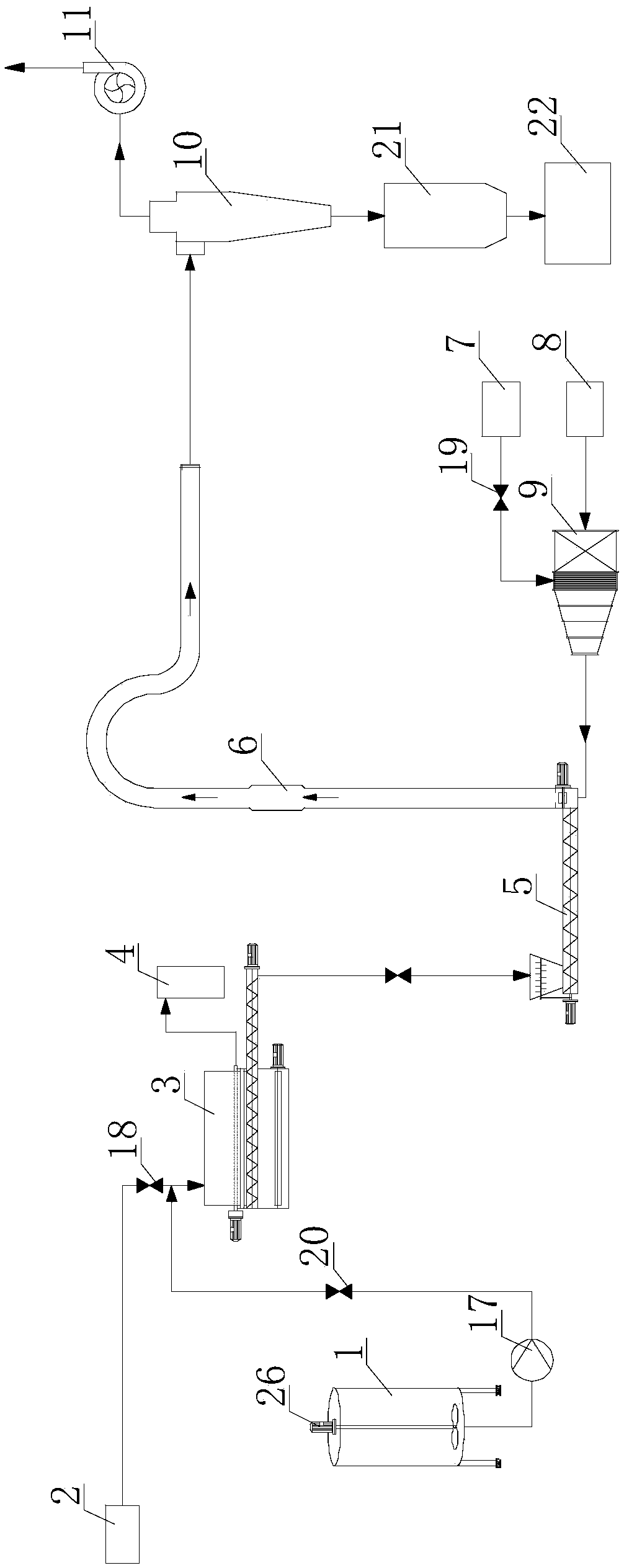

[0049] Such as figure 1 , figure 2 A kind of airflow drying system shown, it comprises emulsion tank 1, water tank 2, vacuum dehydrator 3, air-water separation tank 4, feeding unit 5, airflow drying tower 6, steam source 7, fresh air source 8, heat exchange Device 9, cyclone collector 10, exhaust fan 11, PLC controller 12, dehydrator storage tank level gauge 13 arranged in vacuum dehydrator 3, steam pipe arranged at the steam inlet of heat exchanger 9 Pressure sensor 14, the airflow drying tower intake air temperature sensor 27 that is located on the airflow drying tower 6 air intake ducts, the micro-negative pressure sensor 15 that is located in the airflow drying tower 6 and the exhaust air that is located on the airflow drying tower 6 outlet pipelines temperature sensor 16;

[0050] The outlet of the emulsion tank 1 is connected with the emulsion inlet of the vacuum dehydrator 3, and the pipeline connecting the emulsion tank 1 and the vacuum dehydrator 3 is provided with...

Embodiment 2

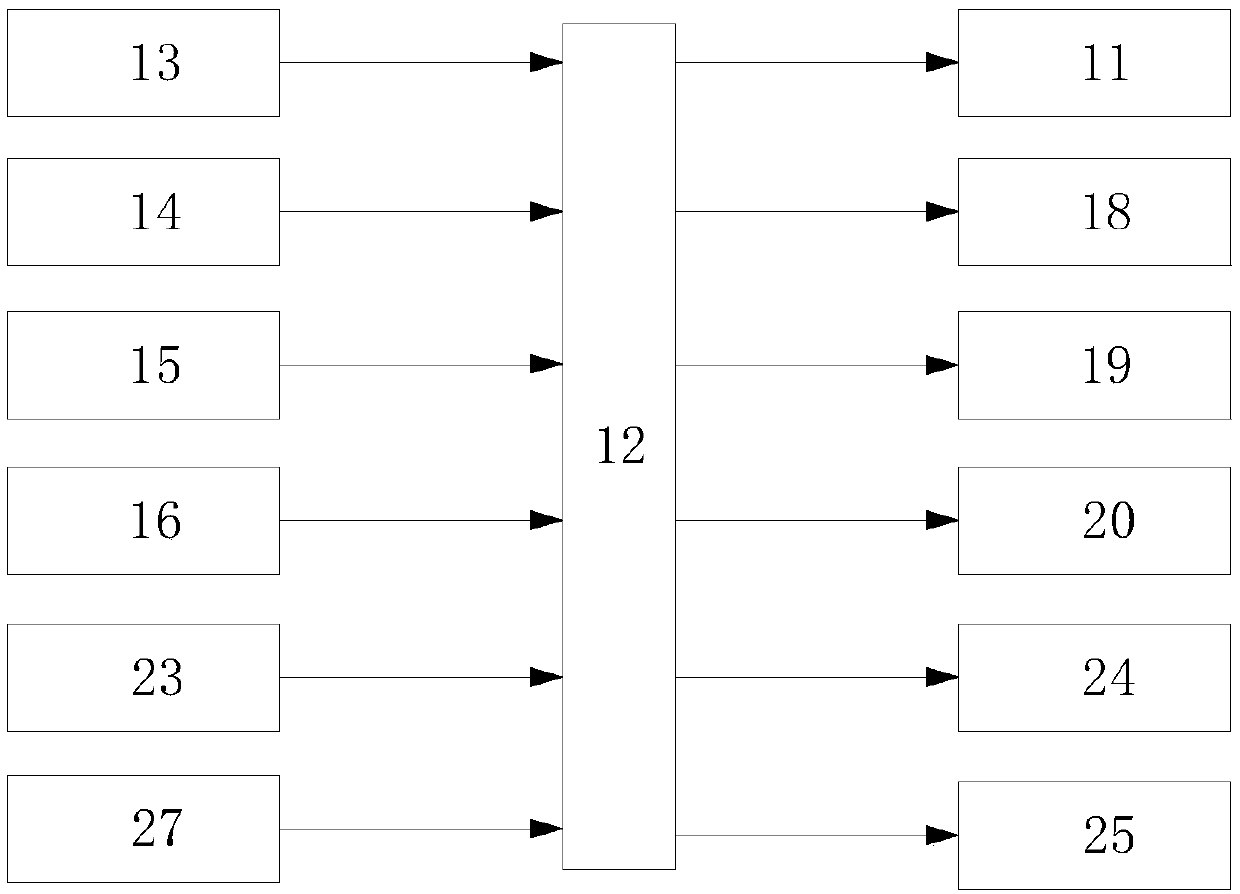

[0059] Such as image 3As shown, the method for stably controlling the product moisture content of the airflow drying system of Embodiment 1 includes a PLC controller 12, a detection device and an actuator, the signal output end of the detection device is connected with the signal input end of the PLC controller 12, and the PLC The signal output end of the controller 12 is connected with the signal input end of the actuator; wherein, the detection device includes a dehydrator storage tank liquid level gauge 13, an airflow drying tower inlet air temperature sensor 27, a steam pipeline pressure sensor 14, and a micro-negative pressure sensor 15. The pressure sensor 23 and the exhaust air temperature sensor 16 in the cooling tower; the actuator includes: the water inlet regulating valve 18, the steam regulating valve 19, the exhaust fan 11, the cooling fan 24, the drum motor 25 and the feed regulating valve 20.

[0060] The PLC controller 12 is a whole set of core control modules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com