A method for comprehensive utilization of straw raw materials

A technology for straw and raw materials, which is applied in the directions of microorganism-based methods, fiber raw material processing, biochemical equipment and methods, etc., can solve the problems of low comprehensive utilization rate of straw resources, restricting the healthy development of the acetone-butanol fermentation industry, and large market fluctuations. , to solve the problem of raw material source, improve the comprehensive utilization value, reduce the dosage and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

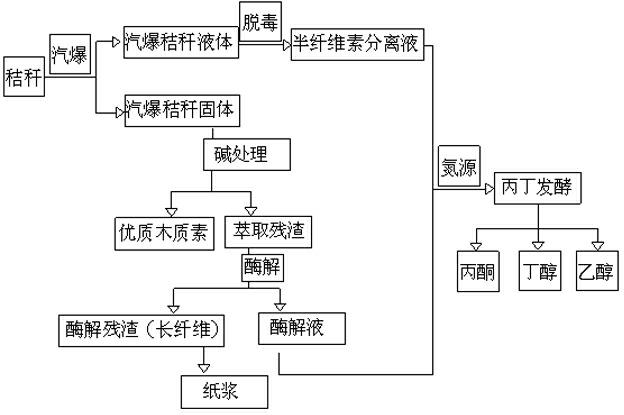

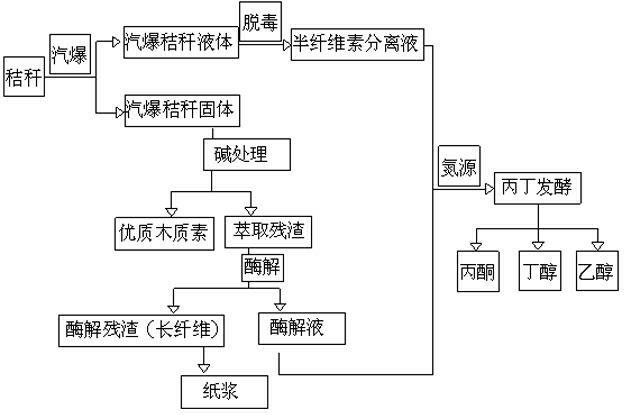

[0017] Such as figure 1 As shown, a method for comprehensive utilization of straw raw materials, the process steps are: a. Take 500 parts of wheat straw, add 750 parts of water, soak for 3 minutes, soak the wheat straw for 3 minutes at a pressure of 0.5Mpa, and obtain steam-exploded wheat straw , add 500 parts of water to the steam-exploded wheat straw, control the temperature at 60°C and fully soak for 15 minutes, then use a screw extruder to separate the steam-exploded wheat straw liquid and the steam-exploded wheat straw solid, so that half of the jade wheat straw The cellulose is fully separated, and the steam-exploded wheat straw solid is steamed and treated with 2% sodium hydroxide at 80°C for 40 minutes, and solid-liquid separation is carried out to obtain the extraction slag and extract respectively, and the extract is extracted with 10% sulfuric acid The pH of the liquid is adjusted to 3.0, the temperature is kept at 50°C, and the acid precipitation time is 30 minutes...

Embodiment 2

[0021] Such as figure 1 As shown, a method for comprehensive utilization of straw raw materials, the process steps are: a. Take 500 parts of corn stalks, add 500 parts of water, soak for 4 minutes, soak the corn stalks at a pressure of 1Mpa for 5 minutes, and obtain steam-exploded corn stalks. Add 750 parts of water to the steam-exploded corn stalks, control the temperature at 65°C and fully soak for 20 minutes, then use a screw extruder to separate the steam-exploded corn stalks into two parts, the liquid and the steam-exploded corn stalks, so that the hemicellulose in the corn stalks Fully separated, steam-exploded corn stalk solids were cooked with 3% sodium hydroxide at 90°C for 60 minutes, and solid-liquid separation was carried out to obtain the extraction residue and extract respectively, and the extract was adjusted with 10% sulfuric acid. pH to 3.2, temperature maintained at 55°C, and acid precipitation time of 40 minutes, the precipitated lignin was filtered through ...

Embodiment 3

[0025] Such as figure 1 As shown, a method for comprehensive utilization of straw raw materials, the process steps are: a. Take 500 parts of straw, add 700 parts of water, soak for 4 minutes, soak the straw for 15 minutes at a pressure of 2Mpa, and obtain the steam-exploded straw. Add 700 parts of water to the straw, control the temperature at 68°C and fully soak for 30 minutes, then use a screw extruder to separate the steam-exploded straw liquid and the steam-exploded straw solid, so that the hemicellulose in the straw can be fully separated, and the steam-exploded straw The solid was cooked at 110°C with 4% sodium hydroxide for 100 minutes, and solid-liquid separation was carried out to obtain the extraction residue and extract respectively. The pH of the extract was adjusted to 3.4 with 10% sulfuric acid, and the temperature was kept at 58 ℃, the acid analysis time is 50 minutes, and the precipitated lignin is filtered through an 80-mesh plate frame to obtain wet lignin, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com