Steam generator and method for controlling generation of water scale in steam generator

A steam generator and internal control technology, applied in steam generation methods, steam generation, control systems, etc., can solve problems such as increased operating costs, water remaining inside, scale generated by heating tube heaters, etc., to reduce the occurrence of scale Probability, avoidance of scaling, avoidance of reduced safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

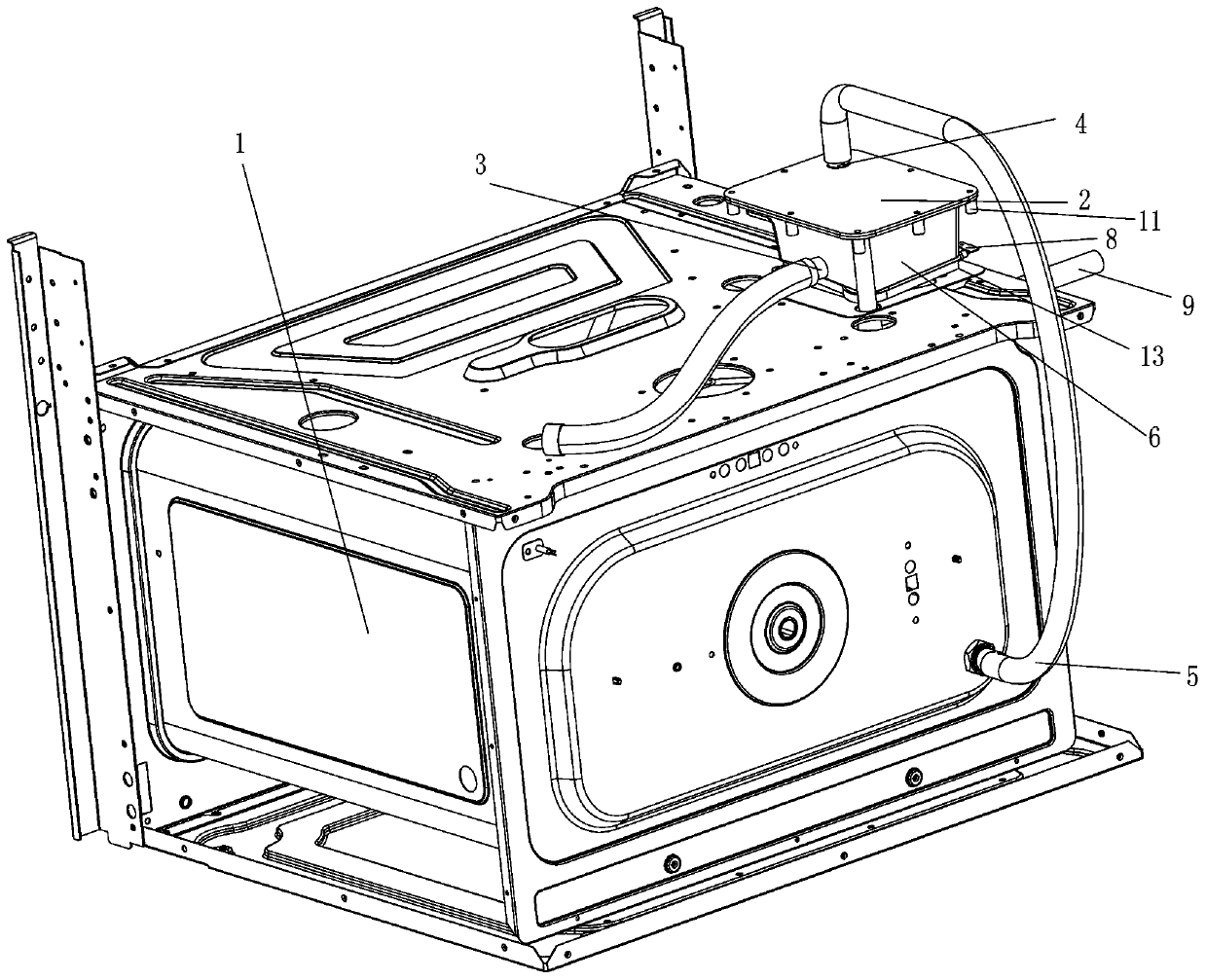

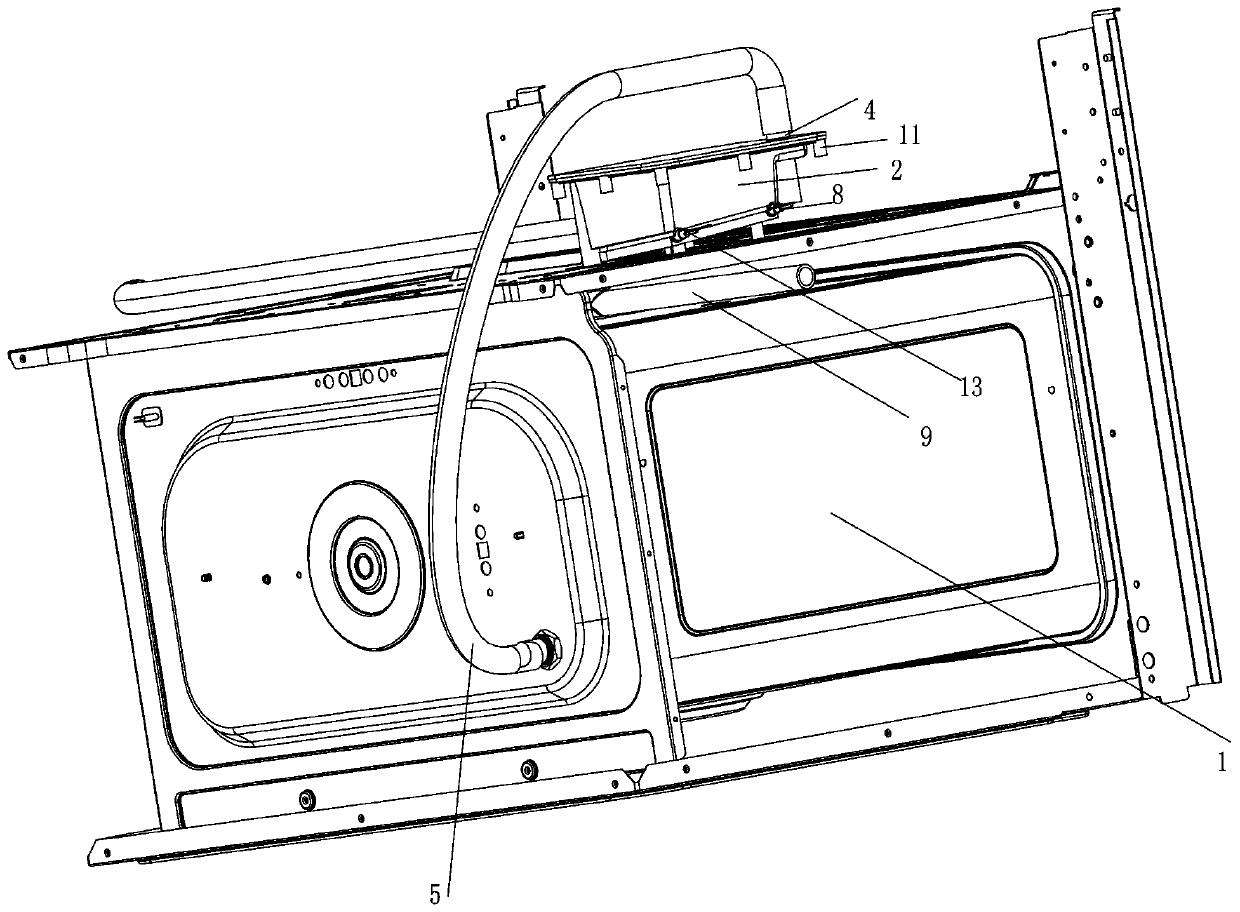

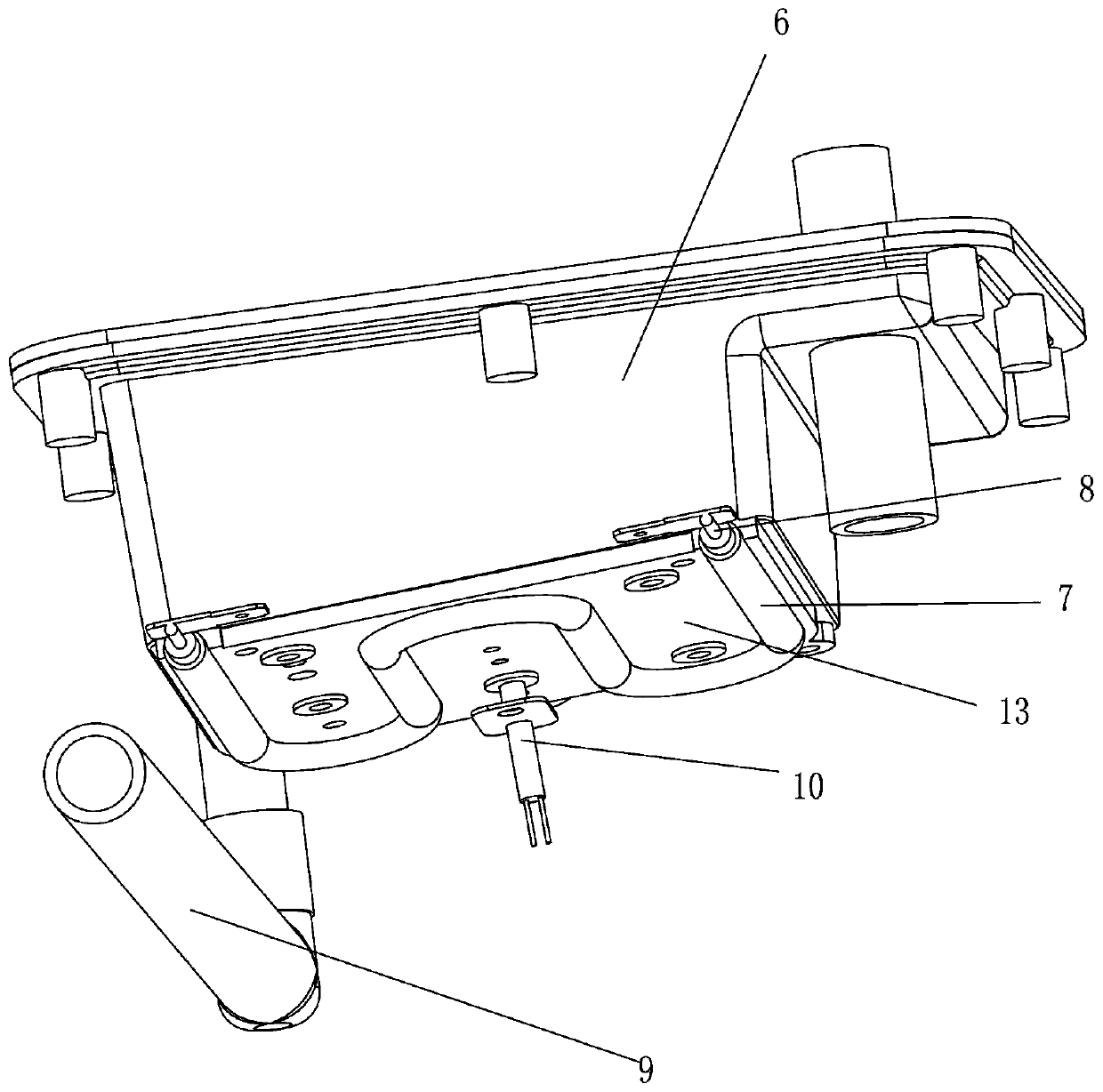

[0025] like Figure 1 to Figure 5 As shown, a steam generator disclosed in this embodiment includes a steam generator body 2, the steam generator body 2 includes a heat conduction shell 6 and a heating body 7 located below the heat conduction shell 6, and the heat conduction shell The lower part of one side of 6 is provided with a cold water inlet 3, the top of the heat conduction shell 6 is provided with a steam outlet 4, the cold water inlet 3 is connected to the corresponding cold water tank through a pipeline, and the steam outlet 4 is connected to the steam outlet 4 through an air duct 5 The furnace cavity 1, the two heating connection ends 8 of the heating body 7 are connected to the corresponding power supply device, the bottom of the heat conducting shell 6 is inclined, and the lowest end of the bottom of the heat conducting shell 6 is connected with a The drain pipe 9 for the remaining water discharge is provided with a temperature sensor 10 in the heat conduction she...

Embodiment 2

[0037] Such as Figure 6 As shown, a steam generator disclosed in this embodiment, as a preference, improves the requirement of discharging excess water and further avoids the generation of scale. The specific structure of the inclined shape at the bottom of the heat conducting shell 6 is: The bottom is provided with an inclined funnel 12, and the lower opening of the inclined funnel 12 is connected with the drain pipe 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com