Waterproof type single-layer lining structure applicable to fourth level surrounding rock double-line track and manufacturing method thereof

A waterproof, surrounding rock technology, applied in tunnel lining, wellbore lining, tunnel, etc., can solve the problems of difficult maintenance of waterproof system ring longitudinal drainage system, difficult to guarantee waterproof effect, and unfavorable rapid tunnel construction, etc. Participate in the effect of good flexural strength performance, small thickness and reducing construction pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

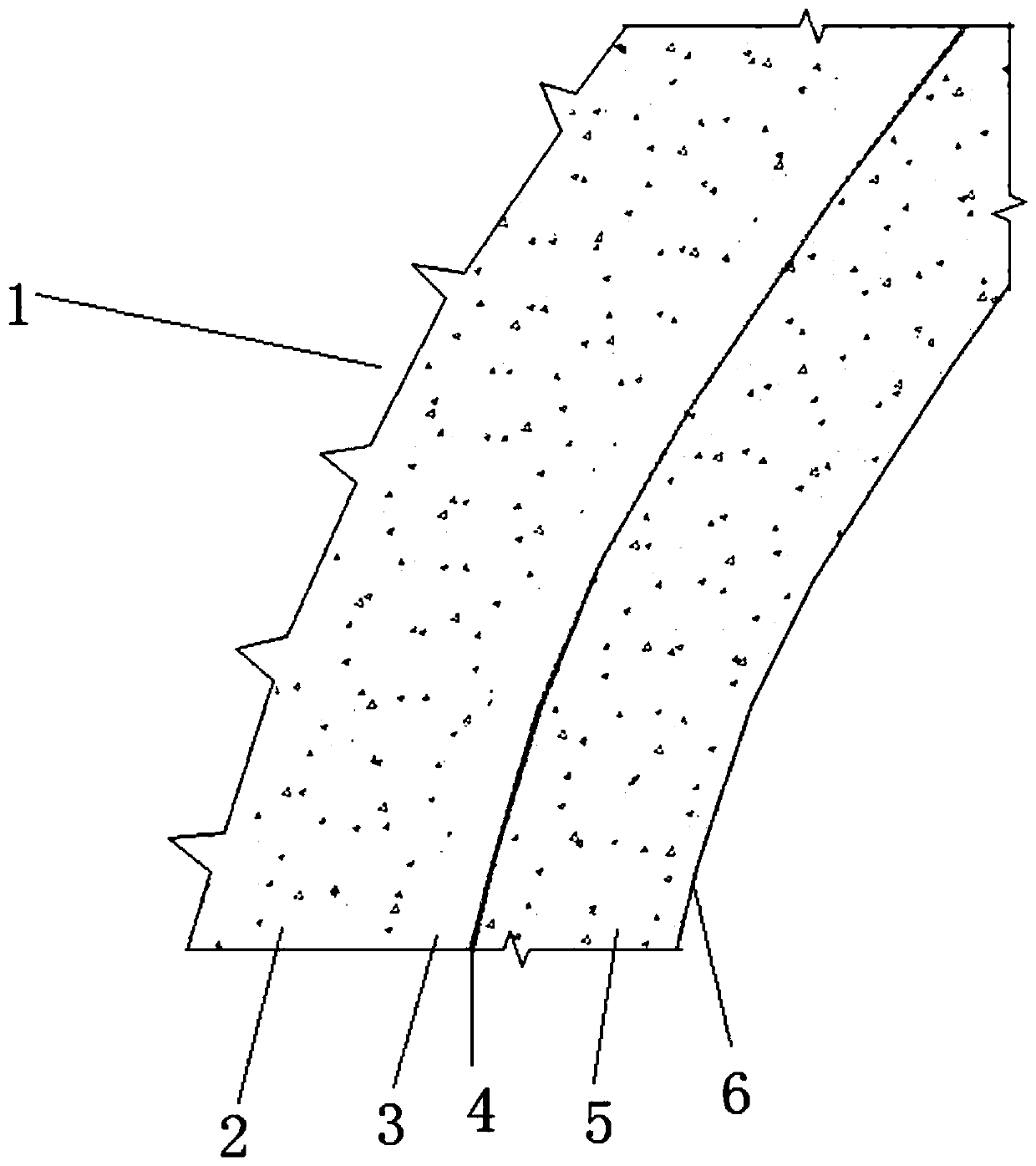

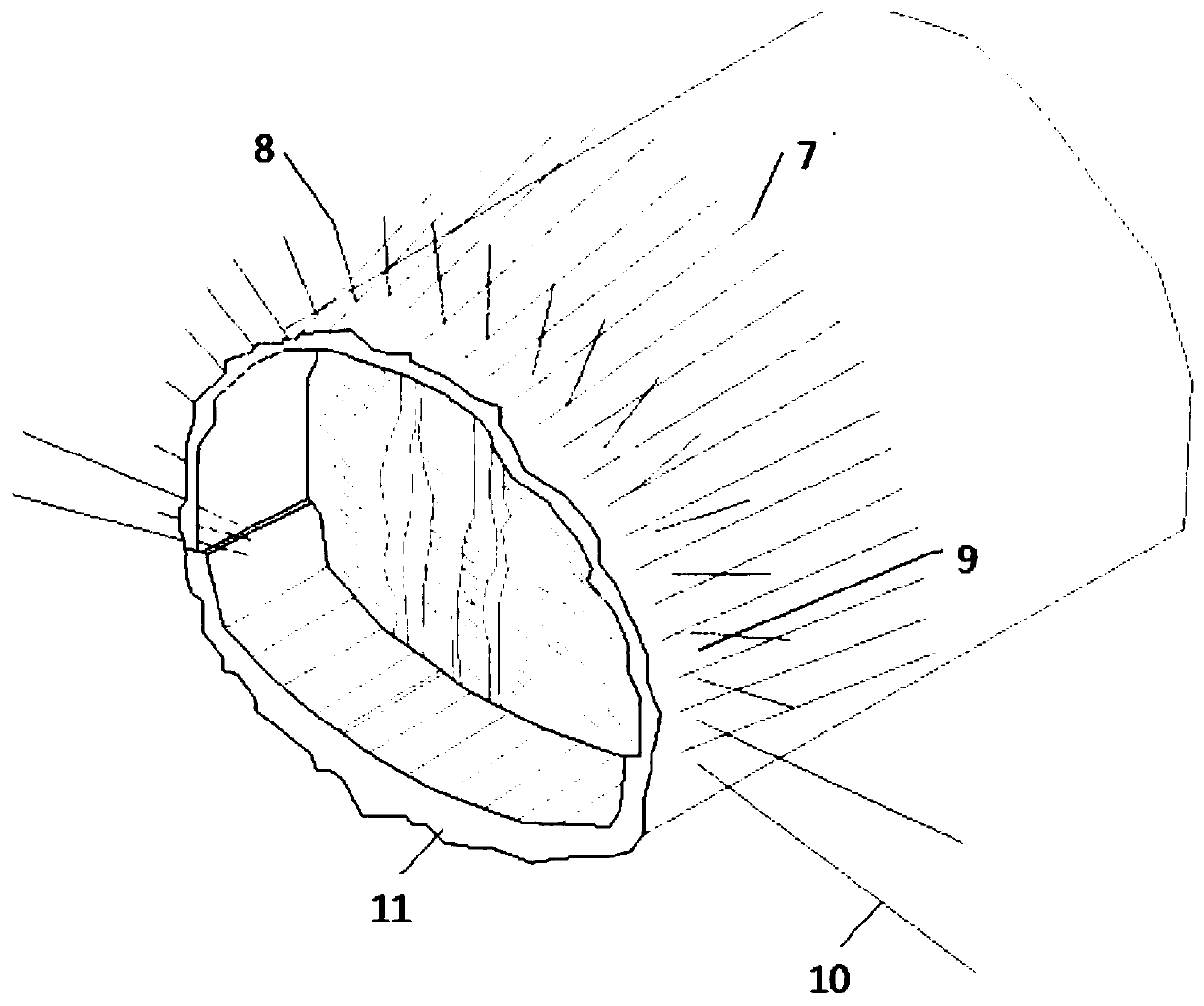

[0040] like figure 1 and image 3 As shown, a waterproof single-layer lining structure suitable for the double-track track in the fourth-grade surrounding rock. After excavation, the fourth-grade surrounding rock is subjected to smooth blasting, the top is chiseled to remove dangerous stones, the grouting is performed in advance, and the Ω-shaped spring is laid. Drainage half-pipe, install anchor rod, anchor rod is divided into horizontal anchor rod and longitudinal anchor rod, clean the rock surface, spray the first layer of coarse fiber concrete and curing, spray mortar and curing, spray waterproof and curing, spray the second layer of fine fiber Concrete and maintenance; that is, from the contact boundary with the rock, the surrounding rock structure is coarse fiber concrete layer 2, mortar layer 3, waterproof layer 4, fine fiber concrete layer 5, and building boundary 6.

[0041] For the smooth surface blasting, the residual eye mark rate should not be less than 80%, and ...

Embodiment 2

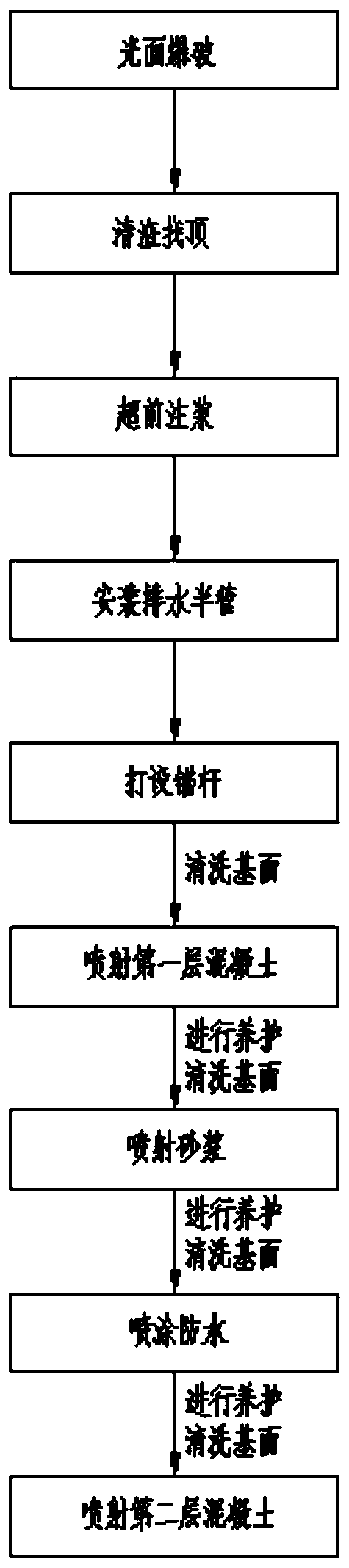

[0051] like figure 2 As shown, a method for making a waterproof single-layer lining structure suitable for four-level surrounding rock double-track tracks includes the following steps:

[0052] (1) Smooth surface blasting is carried out for grade IV surrounding rock. Control the blasting intensity, generally at 1.5cm. For buildings that are sensitive to the blasting vibration velocity after evaluation, control according to the evaluation results. If necessary, adopt mechanical excavation or static blasting; take seismic isolation measures and use "weak blasting" technology to control vibration Speed up, minimize the distance between the peripheral eyes, and control the dosage.

[0053] (2) After blasting and slag removal, it is necessary to carry out roof search operations to clean up dangerous rocks on the top and side walls to ensure site safety;

[0054] (3) The main purpose of advanced grouting is to strengthen the surrounding rock, ensure the safety of construction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com