Side plate connecting beam and column joint structure and connecting method

A technology of beam-column joints and side plates, which is applied to building structures and buildings, can solve problems such as poor plastic rotation capacity, difficulty in realizing the outward movement of plastic hinges on beams, strong joints and weak members, seismic requirements, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

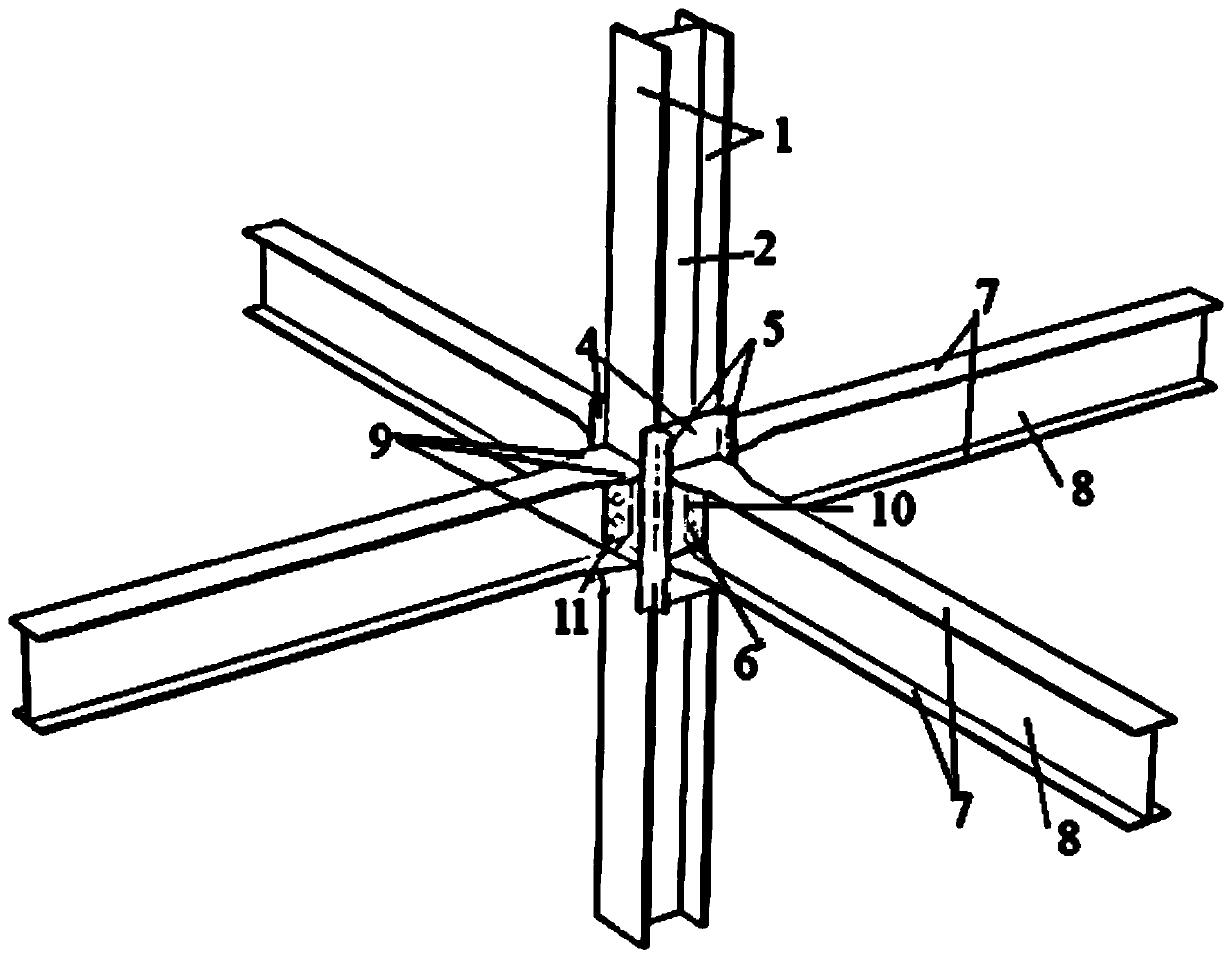

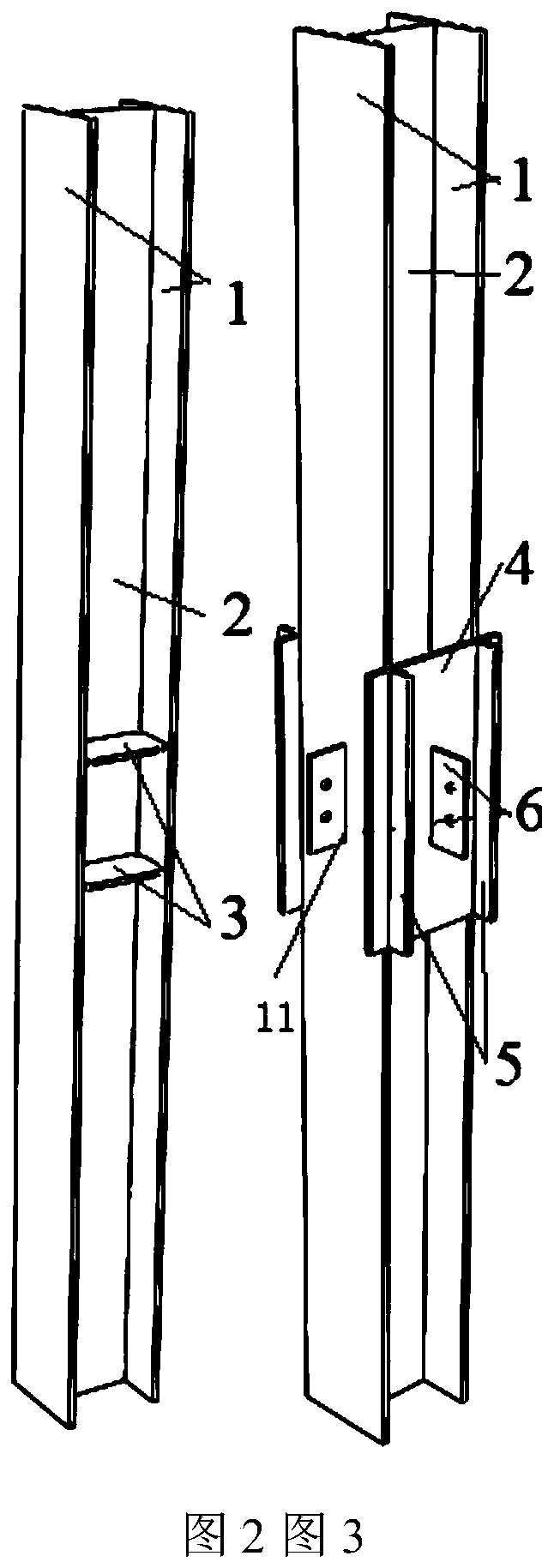

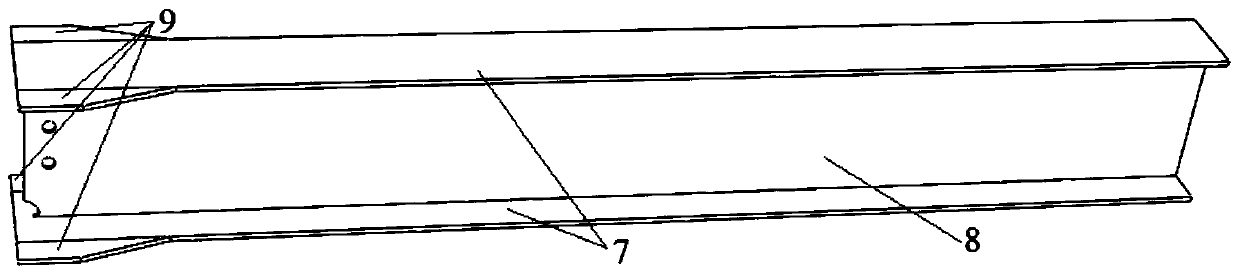

[0032] Such as Figure 1 to Figure 4 As shown, a side plate connection beam-column joint structure includes H-shaped beams, H-shaped columns, transverse stiffeners 3, side plates 4, ear plates 5, connecting plates 6 and wing expansion plates 9, and the H-shaped beam includes two Beam flanges 7 arranged in parallel, a beam web 8 is arranged between the two beam flanges 7, the plane where the largest surface of the beam web 8 is perpendicular to the plane where the largest surface of the beam flange 7 is located; the H-shaped column includes two parallel column flanges 1, A column web 2 is arranged between two column flanges 1, and the plane where the largest surface of the column flange 1 is located is perpendicular to the plane where the largest surface of the column web 2 is located; Stiffener 3, the plane where the largest face of transverse stiffener 3 is perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com