Acrylic emulsion and preparation method thereof

A technology of acrylic emulsion and solid acrylic acid, which can be used in inks, coatings, household utensils, etc., and can solve the problems of poor water resistance, high temperature sensitivity, and poor ethanol stability of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

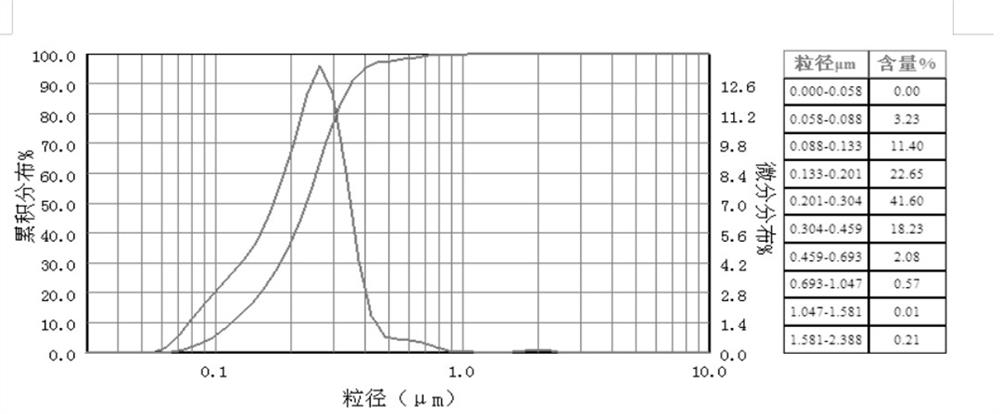

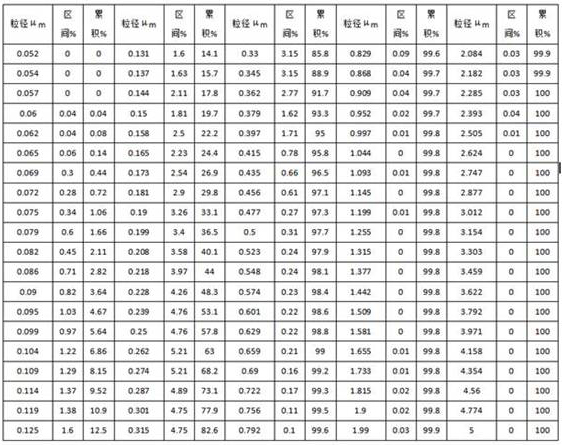

Image

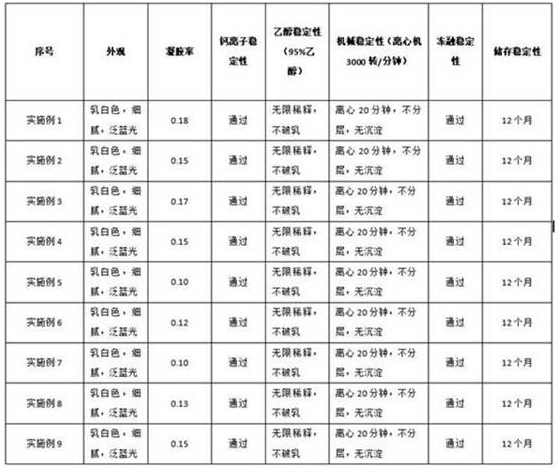

Examples

preparation example Construction

[0020] The preparation method of above-mentioned acrylic acid emulsion comprises the following steps:

[0021] (1) Alkali-soluble solid acrylic resin with a molecular weight of 4000-12000 and an acid value of 170-250mgKOH / g and alkaline substances are dissolved in water at 60-80°C to form an alkali-soluble solid acrylic resin solution with a mass concentration of 30%;

[0022] (2) Add deionized water to the acrylic resin liquid obtained in step (1), add mixed monomers accounting for 5~10% of the total amount during the stirring process, and add NaHCO when the temperature rises to 70°C 3 and the initiator accounting for 30% of the total amount, keep warm at 80~85°C for 30-40 minutes;

[0023] (3) Add the remaining mixed monomers and 60% of the total amount of initiator at 80~85°C to the reactor dropwise within 3~4 hours; then add the rest of the initiator at 80~85°C Insulate and react at high temperature for 1-1.2 hours; naturally lower the temperature to 40-60° C., adjust the...

Embodiment 1

[0037] Take St 24.08g, BA 30.24g, HEMA 1.68g, as a mixed monomer for later use, take 0.50g K 2 S 2 o 8 , dissolved in 15.12g deionized water, and used as an initiator solution for subsequent use.

[0038] Add 24g Soluryl 70, 48g water, and 8g ammonia water (26%) into a 500 mL four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, raise the temperature to 65°C, and react for 1.5 h until the resin is completely dissolved. Add 48.9g of deionized water, stir well, add 2.8g of mixed monomers, stir fully at 500r / min for 20 minutes, start to heat up, at 70°C, add 4.69g of K 2 S 2 o 8 Aqueous solution, 0.112g NaHCO 3 , reacted for 30 minutes at 80°C (the emulsion appeared light blue, and when the reflux of the monomer was completed, the emulsion was milky white); then, added dropwise the remaining 53.2g mixed monomer and 9.38g K 2 S 2 o 8 Aqueous solution, add dropwise at a constant speed, the whole dropping process is controlled within 3~4 h; after ...

Embodiment 2

[0040] Take St 24g, BA 33g, N-methylolacrylamide 3g, as a mixed monomer for later use, take 0.54g K 2 S 2 o 8 , dissolved in 16.2g deionized water, and used as an initiator solution for subsequent use.

[0041] Into a 500 mL four-neck flask equipped with a stirrer, a thermometer and a reflux condenser, add 20 g of Soluryl 90, 40 g of water, and 6.7 g of ethanolamine, raise the temperature to 75°C, and react for 1.5 h until the resin is completely dissolved. Add 57.1g of deionized water, stir well, add 4.8g of mixed monomers, stir fully at 500r / min for 20 minutes, start to heat up, at 70°C, add 5g of K 2 S 2 o 8 Aqueous solution, 0.12g NaHCO 3 , react for 0.5 h at 80 ℃ (the emulsion appears light blue, and when the reflux of the monomer is completed, the emulsion is milky white); then, add the remaining 55.2g of mixed monomer and 10g of K 2 S 2 o 8 Aqueous solution, add dropwise at a constant speed, and the whole dropping process is controlled within 3~4 h to complete; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com