High-performance sodium niobate-based leadless pyroelectric ceramic material, and preparation method and application thereof

A pyroelectric ceramic, lead-free heat technology, applied in the field of infrared detection materials, can solve the problems of comparable performance, restrict development and application, affect the sensitivity of infrared detectors, etc., and achieve the effect of excellent performance and high depolarization temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

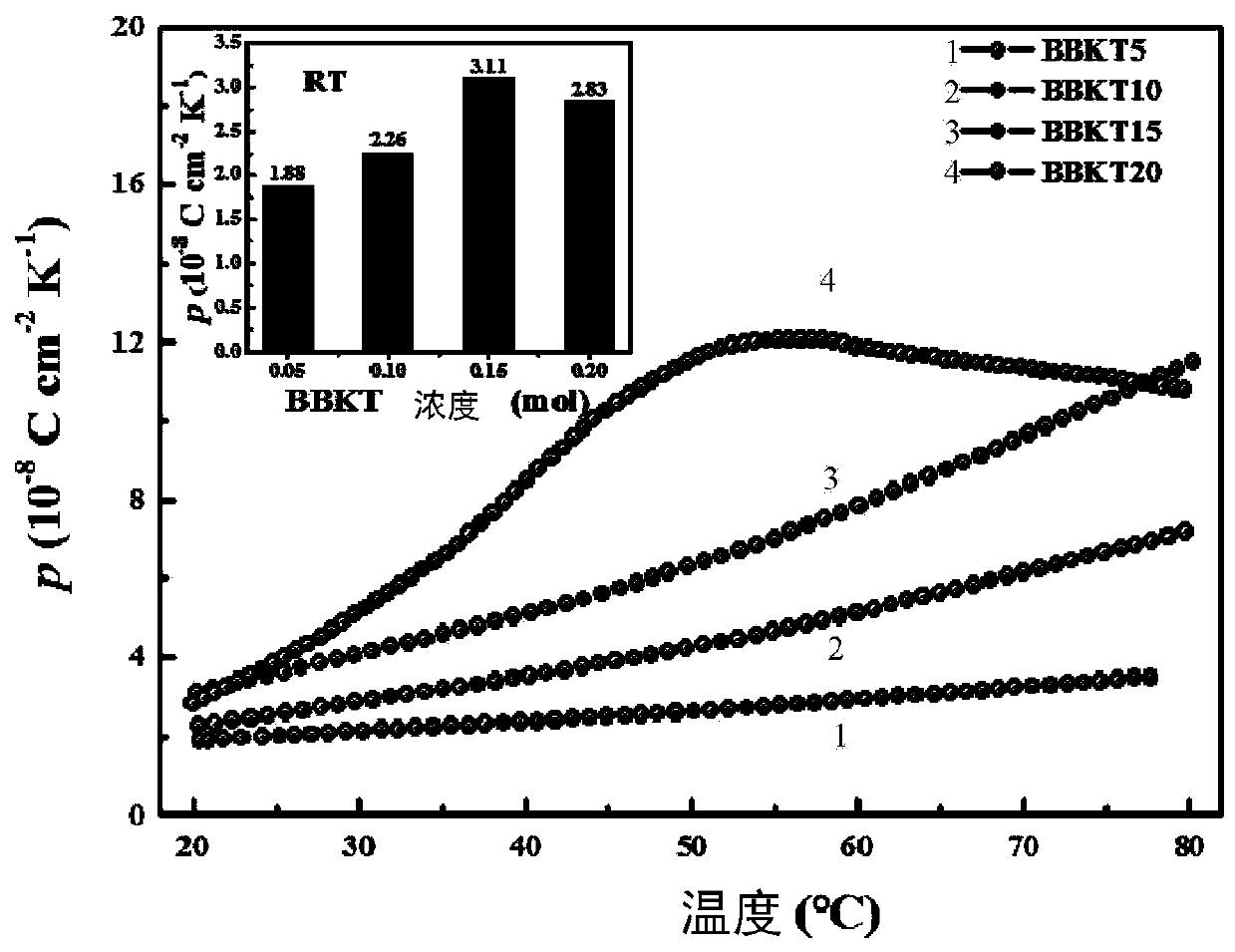

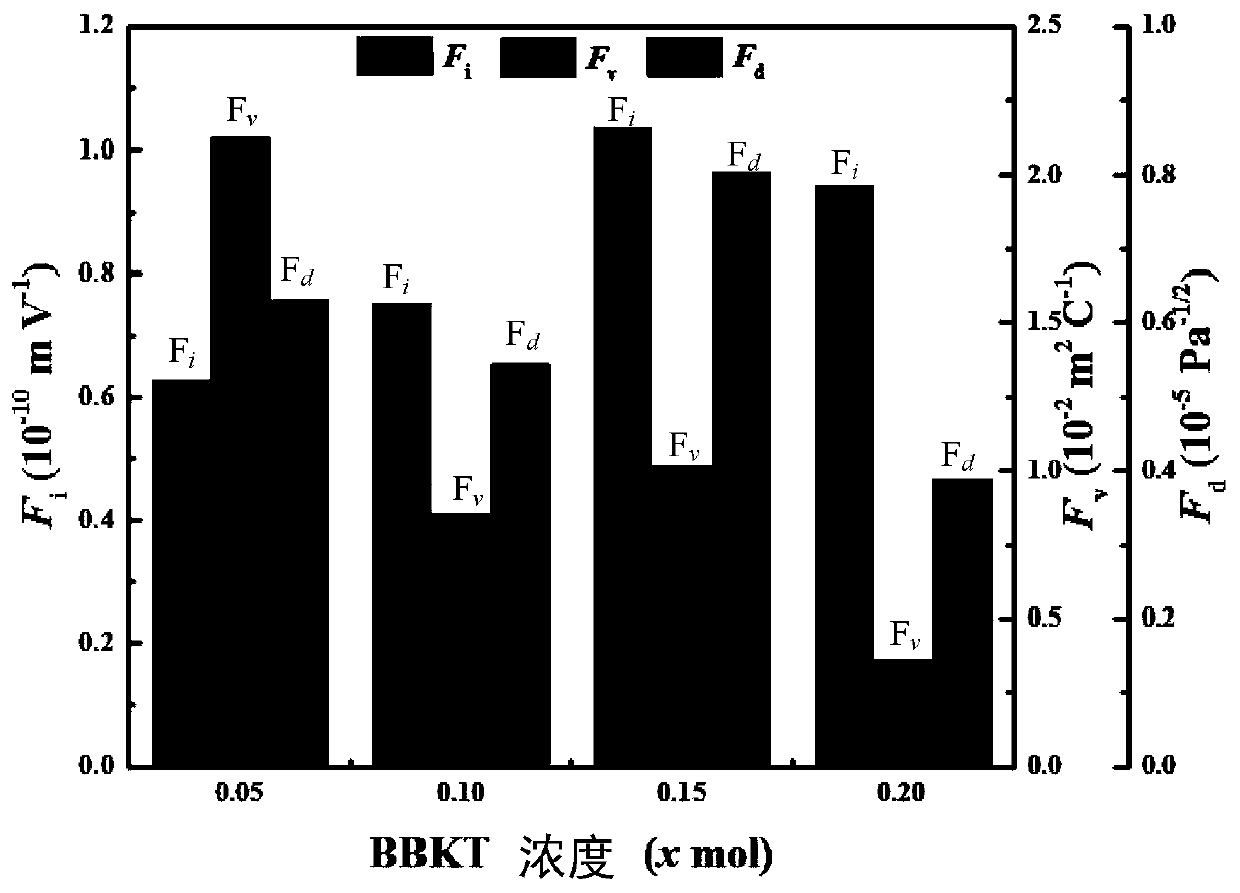

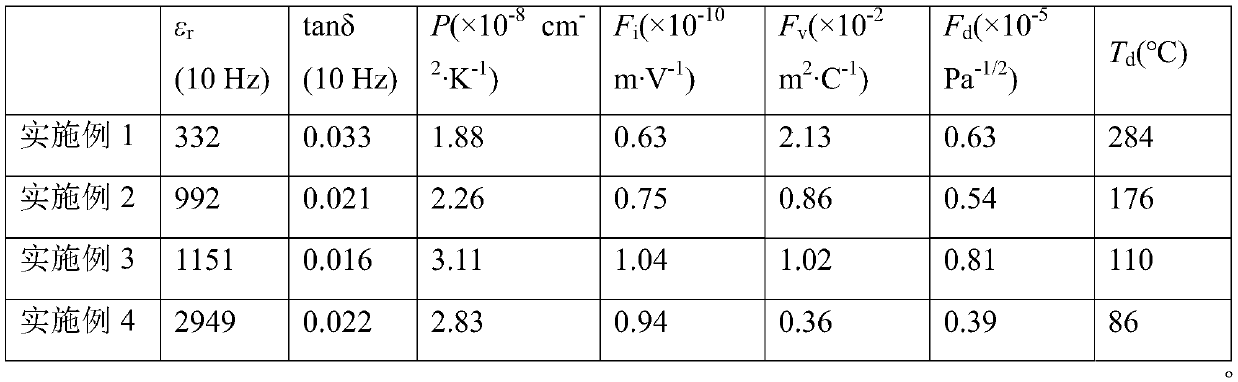

Embodiment 1

[0037] (1) Preparation of (1-x)NaNbO 3 -xBa 0.6 (Bi 0.5 K 0.5 ) 0.4 TiO 3 +1mol%MnCO 3 , the component shown by x=0.05. First according to (1-x)NaNbO 3 -xBa 0.6 (Bi 0.5 K 0.5 ) 0.4 TiO 3 +1mol%MnCO 3 , x=0.05 stoichiometric ratio takes raw material Na 2 CO 3 Powder, Nb 2 o 5 Powder, BaCO 3 Powder, Bi 2 o 3 Powder, K 2 CO 3 Powder, TiO 2 Powder, MnCO 3 Powder, the purity of all raw materials is greater than 99.0%. The wet ball milling method is used for mixing for 24 hours to make the components uniformly mixed, the ball milling medium is zirconium balls, and the solvent is absolute ethanol. Raw materials used: alcohol: zirconium ball ratio is 1: (0.8-1.2): (4-6). Drying, compression molding, and calcination synthesis to obtain (1-x)NaNbO 3 -xBa 0.6 (Bi 0.5 K 0.5 ) 0.4 TiO 3 +1mol%MnCO 3 , x=0.05 solid solution powder. During the synthesis process, the heating rate is 1-3°C / min, the synthesis temperature is 850-1050°C, and the holding time is 1-...

Embodiment 2

[0042] The composition of the material is (1-x)NaNbO 3 -xBa 0.6 (Bi 0.5 K 0.5 ) 0.4 TiO 3 +1mol%MnCO 3 , x=0.10, repeat the preparation method of Example 1 according to the above formula to obtain a polarized pyroelectric ceramic element, and measure the dielectric and pyroelectric properties of the polarized sample without an external electric field.

Embodiment 3

[0044] The composition of the material is (1-x)NaNbO 3 -xBa 0.6 (Bi 0.5 K 0.5 ) 0.4 TiO 3 +1mol%MnCO 3 , x=0.15, repeat the preparation method of Example 1 according to the above formula to obtain a polarized pyroelectric ceramic element, and measure the dielectric and pyroelectric properties of the polarized sample without an external electric field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com