Preparation method of ceramic tile with controllable glaze glossiness and ceramic tile

A technology for gloss and ceramic tiles, which is applied in the field of architectural ceramics production, can solve the problems of uncontrollable glaze gloss, achieve the effects of reducing the difference between surface texture and gloss, promoting color rendering, and simplifying the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

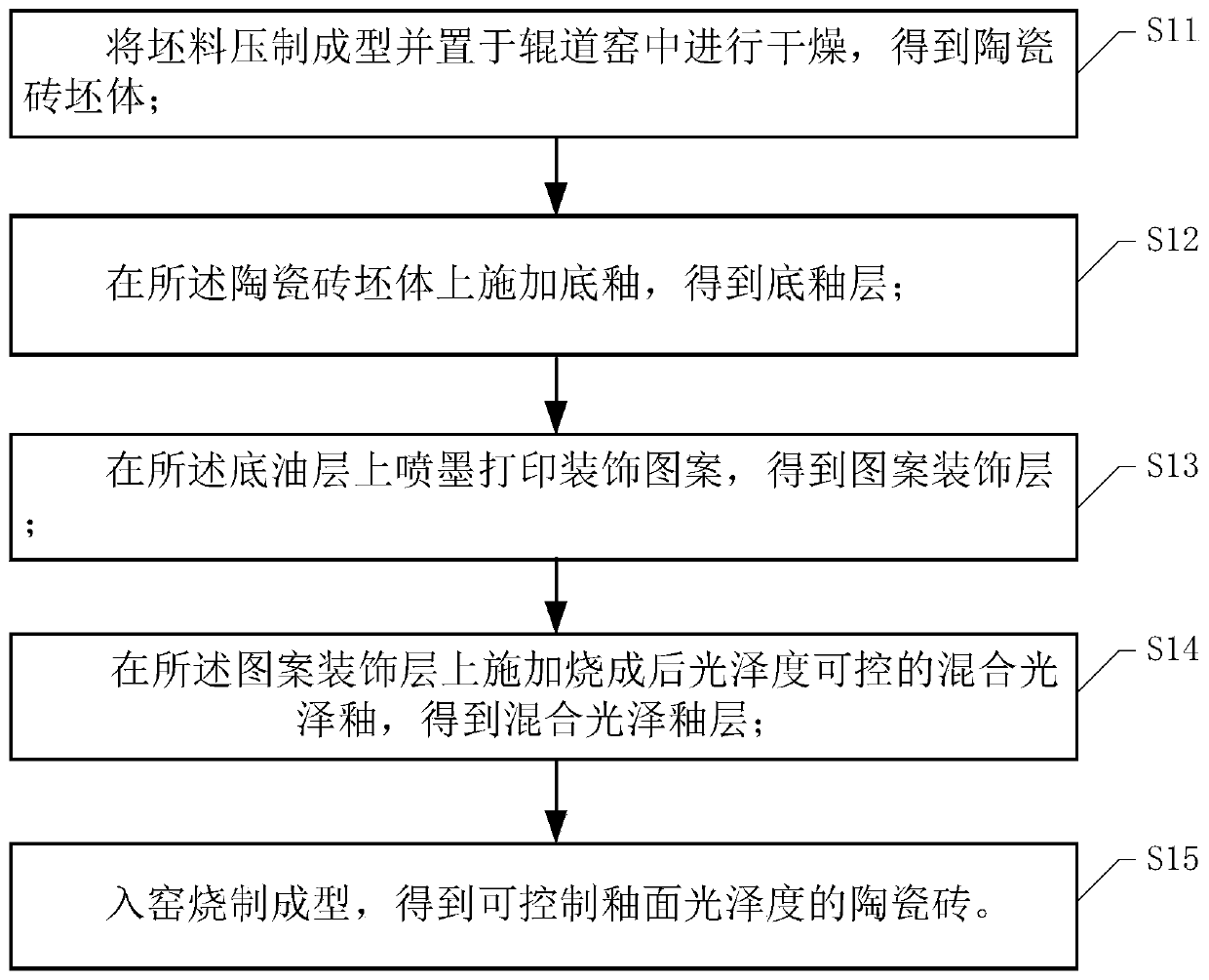

[0067] This embodiment provides a method for preparing ceramic tiles with controllable glaze gloss, which includes:

[0068] Step 11, pressing the blank and placing it in a roller kiln for drying to obtain a ceramic brick body;

[0069] Step 12, applying an underglaze on the ceramic tile body to obtain an underglaze layer;

[0070] Step 13, inkjet printing a decorative pattern on the underglaze layer to obtain a patterned decorative layer;

[0071] Step 14, applying a mixed glossy glaze with controllable gloss after firing on the pattern decoration layer to obtain a mixed glossy glaze layer;

[0072] Step 15, firing in a kiln to obtain ceramic tiles with controllable glaze gloss.

[0073] Further, the chemical composition of the bottom glaze is in mass percentage, including:

[0074] SiO 2 50-55%, Al 2 o 3 25-30%, F 2 o 3 0~0.17%, CaO 0~2%, MgO 3~6%, K 2 O 0~5%, Na 2 O 0~5%, ZrO 2 6-10%.

[0075] Further, the mixed glossy glaze includes matte glaze and / or high ...

Embodiment 2

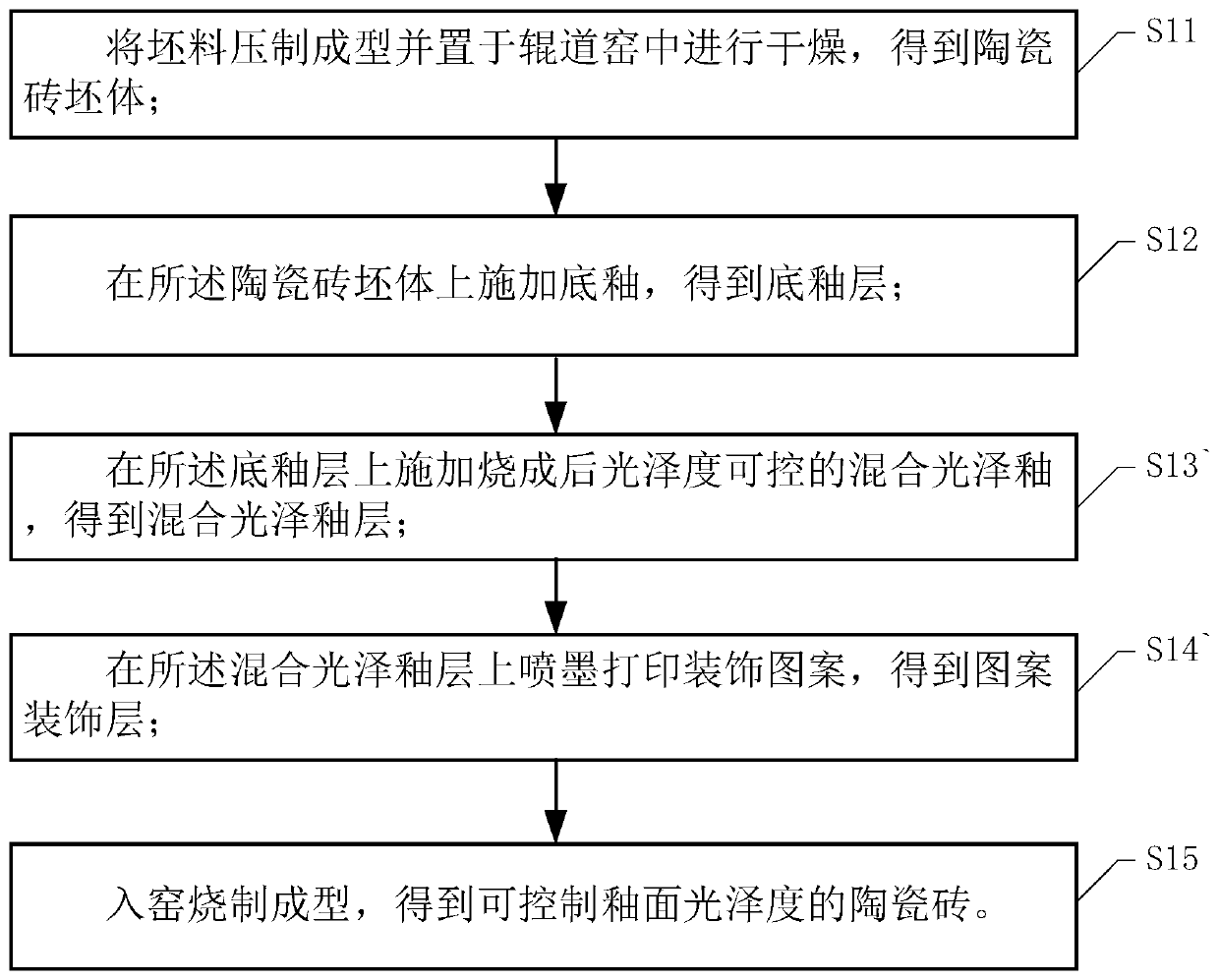

[0085] This embodiment provides a method for preparing ceramic tiles with controllable glaze gloss, which includes:

[0086] Step 11, pressing the blank and placing it in a roller kiln for drying to obtain a ceramic brick body;

[0087] Step 12, applying an underglaze on the ceramic tile body to obtain an underglaze layer;

[0088] Step 13`, applying a mixed glossy glaze with controllable gloss after firing on the bottom glaze layer to obtain a mixed glossy glaze layer;

[0089] Step 14`, inkjet printing decorative patterns on the mixed glossy glaze layer to obtain a pattern decorative layer;

[0090] Step 15, firing in a kiln to obtain ceramic tiles with controllable glaze gloss.

[0091] Further, the chemical composition of the bottom glaze is in mass percentage, including:

[0092] SiO 2 50-55%, Al 2 o 3 25-30%, F 2 o 3 0~0.17%, CaO 0~2%, MgO 3~6%, K 2 O 0~5%, Na 2 O 0~5%, ZrO 2 6-10%.

[0093] Further, the mixed glossy glaze includes matte glaze and / or high...

Embodiment 3

[0102] This embodiment provides a method for preparing ceramic tiles with controllable gloss on the glazed surface. The difference between the first and second embodiments is that the chemical composition of the bottom glaze is expressed in mass percentage, and specifically includes:

[0103] SiO 2 53.37%, Al 2 o 3 26.53%, F 2 o 3 0.17%, CaO 1.38%, MgO 3.98%, K 2 O2.67%, Na 2 O 3.04%, ZrO 2 8.86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com