A kind of injection molding plastic parts outer surface burr cleaning machine

A technology of injection molding plastics and outer surfaces, which is applied in the direction of machine tools, grinding racks, and grinding workpiece supports suitable for grinding workpiece edges, and can solve the problems of uneven deburring parts, low operating efficiency, and high labor costs. Achieve the effect of smooth burr treatment parts, high applicability and good aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

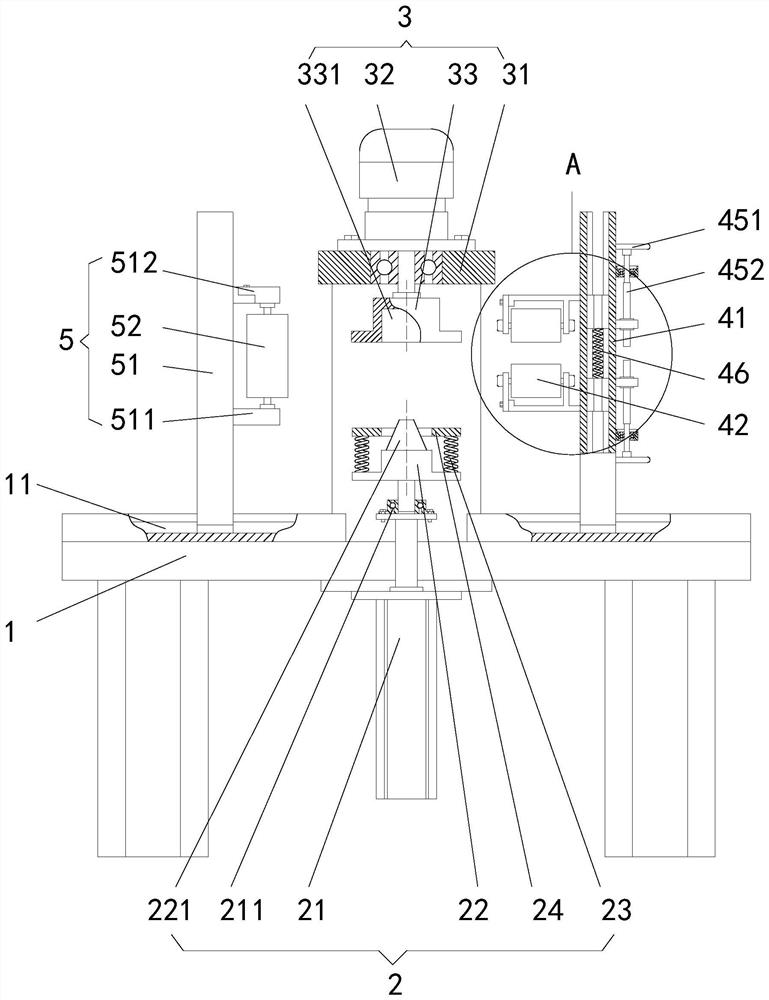

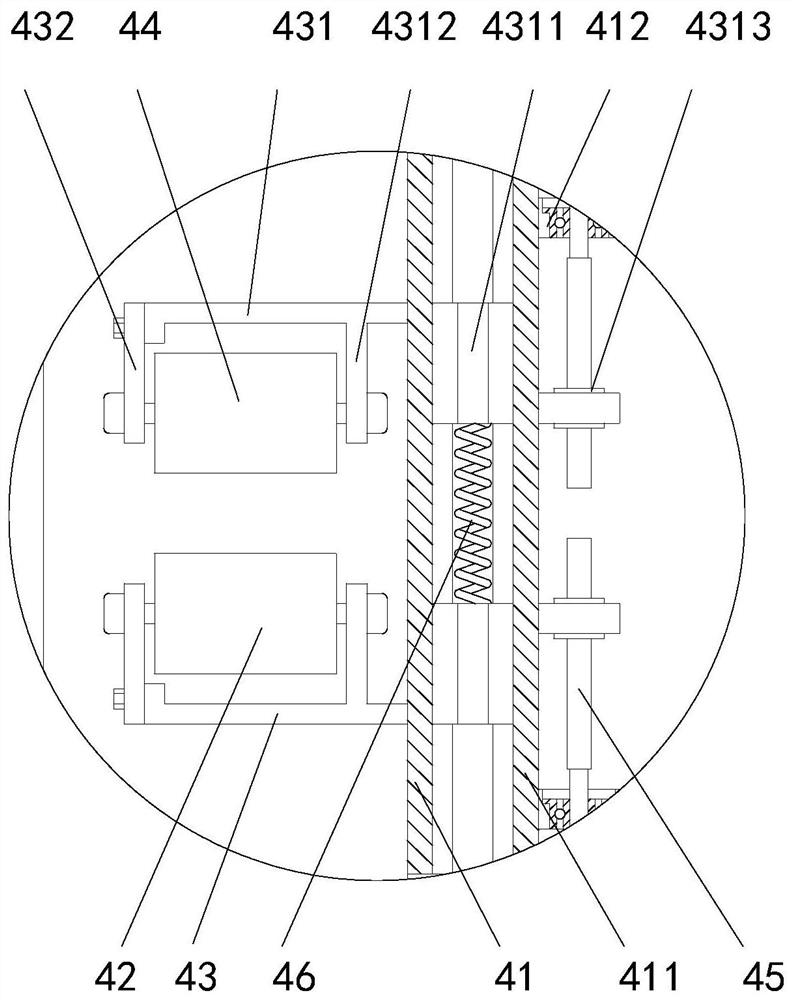

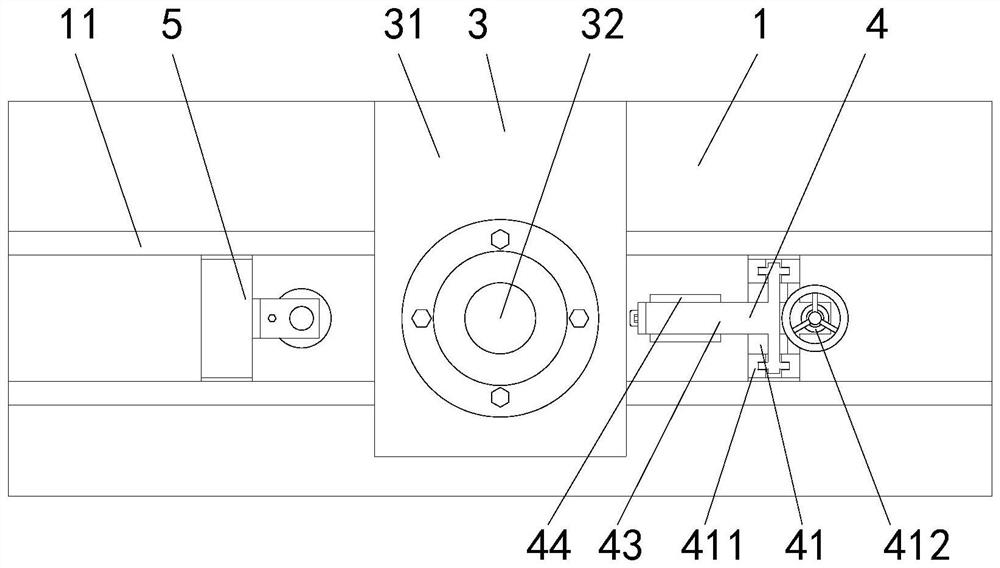

[0022] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

[0023] refer to Figure 1-3 As shown, a machine for cleaning burrs on the outer surface of injection molded plastic parts includes a workbench 1, a jacking and clamping mechanism 2 fixedly installed on the workbench 1, a rotating mechanism 3 fixedly installed on the workbench 1, and a sliding mechanism installed on the workbench The end surface burr removal mechanism 4 on the upper end surface of the table 1 and the side wall burr removal mechanism 5 slidingly installed on the upper end surface of the workbench 1, the rotating mechanism 3 and the jacking and cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com