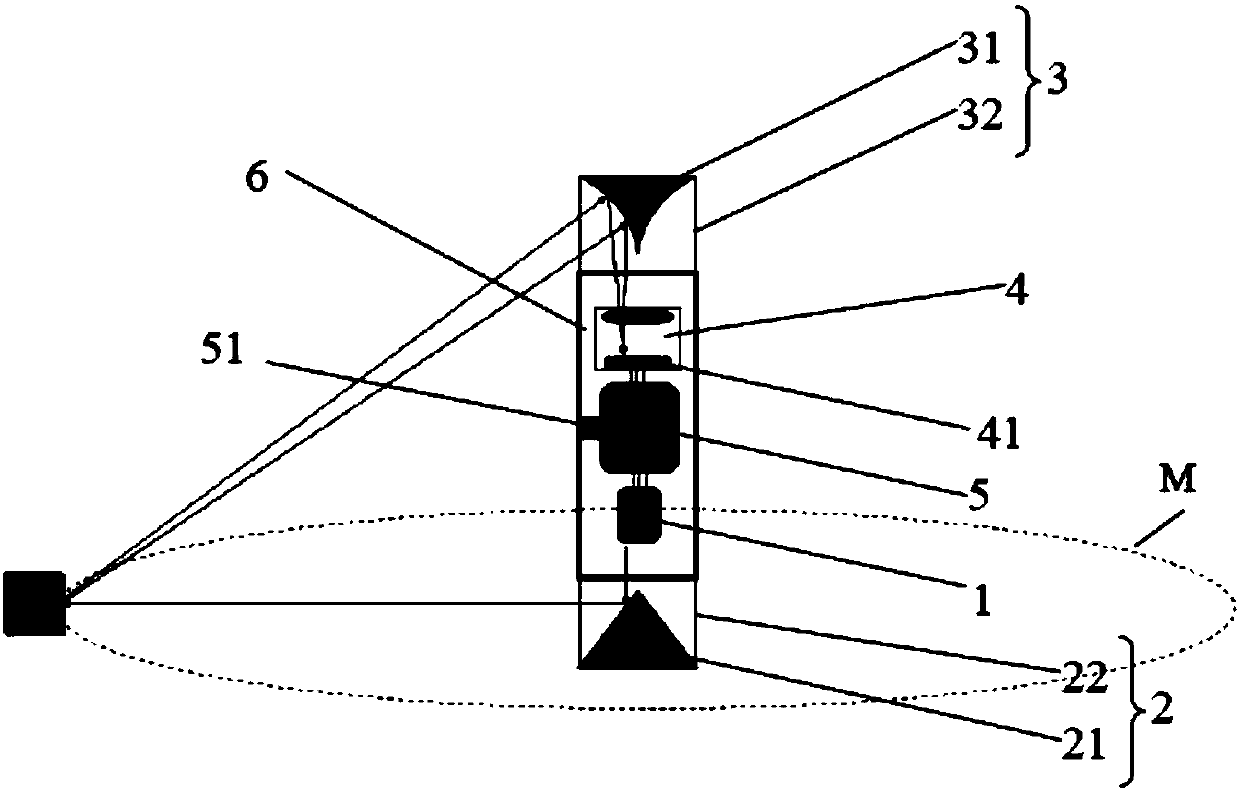

Solid-state annular three-dimensional imaging device

A three-dimensional imaging, ring-shaped technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as unfavorable device wiring, unfavorable device high-precision measurement, unfavorable camera formation and other problems, and achieves easy calibration, simple structure, and system size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] Such as Figure 5As shown, the difference between the second embodiment and the first embodiment is that the inverted cone reflection module 3 and the area light receiving module 4 in the first embodiment are replaced by a panoramic camera camera module 7 coaxial with the axis of the light emitting module 1, Other structural features of the second embodiment are the same as those of the first embodiment, and will not be repeated here.

Embodiment 3

[0044] Such as Image 6 As shown, the difference between the third embodiment and the first embodiment is that the inverted cone reflection module 3 and the area light receiving module 4 in the first embodiment are replaced by an ultra-wide-angle camera module that is coaxial or perpendicular to the axis of the light emitting module 1 8. Other structural features of the third embodiment are the same as those of the first embodiment, and will not be repeated here.

Embodiment 4

[0046] Such as Figure 7 As shown, the difference between the fourth embodiment and the first embodiment is that the inverted cone reflection module 3 and the area light receiving module 4 in the first embodiment are replaced by a wide-angle camera module 9 perpendicular to the axis of the light emitting module 1 . Other structural features of the fourth embodiment are the same as those of the first embodiment, and will not be repeated here.

[0047] The invention can realize ring-shaped three-dimensional imaging, and does not need a motor to drive parts to rotate, has a solid structure completely, and has the characteristics of simple structure, easy calibration and high service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com