Diesel oil and natural gas dual-fuel engine nozzle working method

A dual-fuel engine and working method technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of poor atomization effect, high use cost, low reliability, etc., and achieve improved reactivity, improved combustion, Improve the effect of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

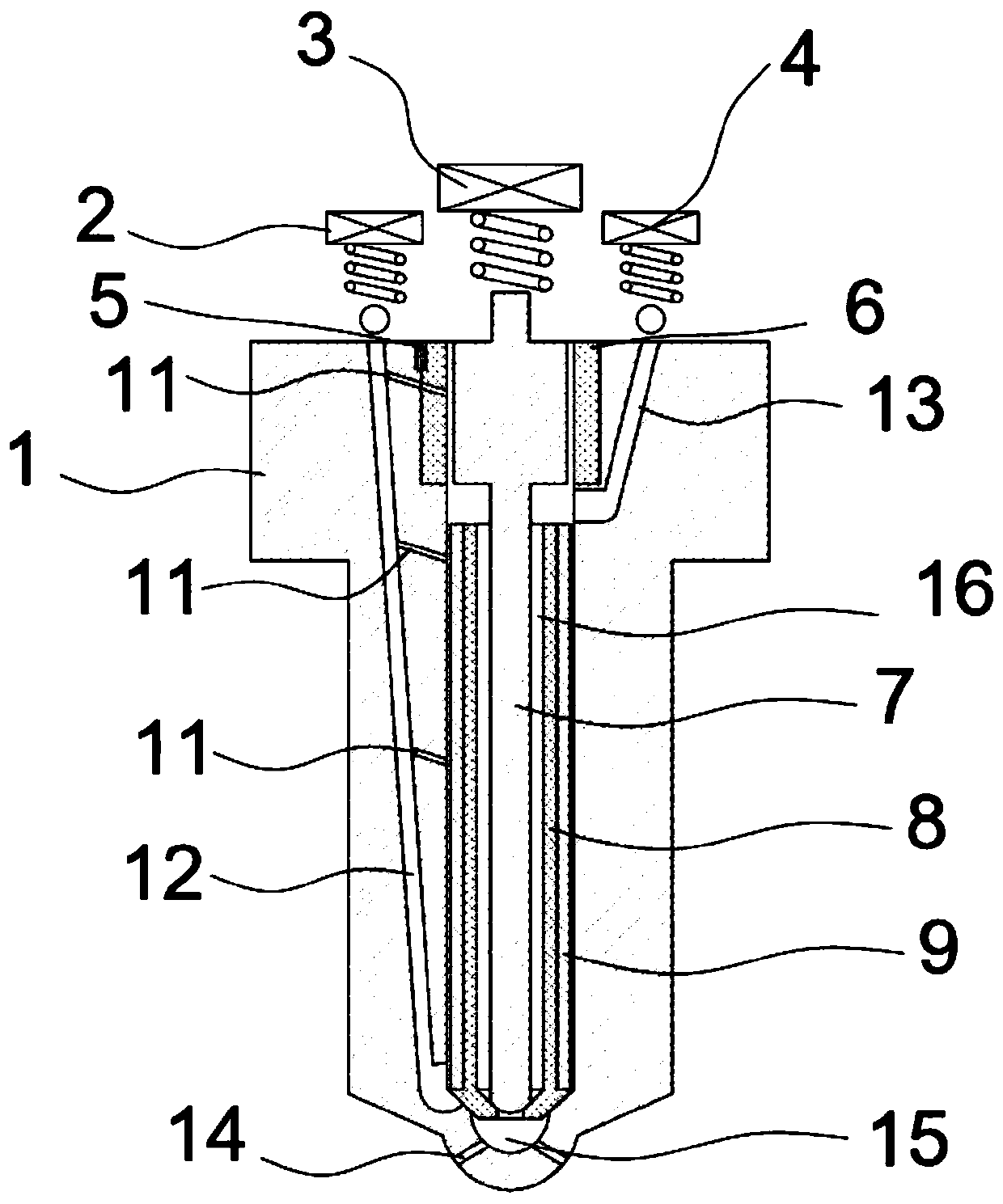

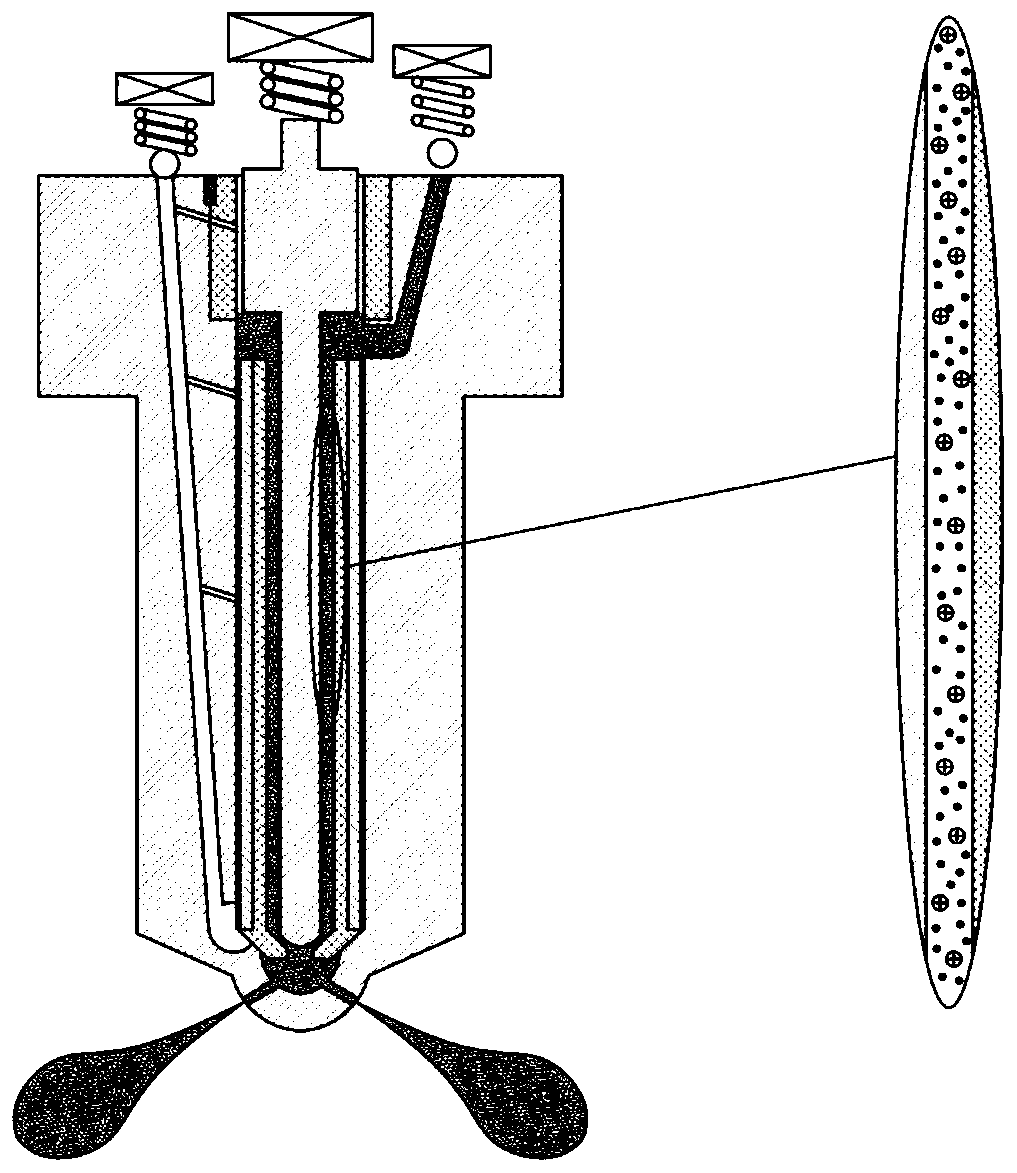

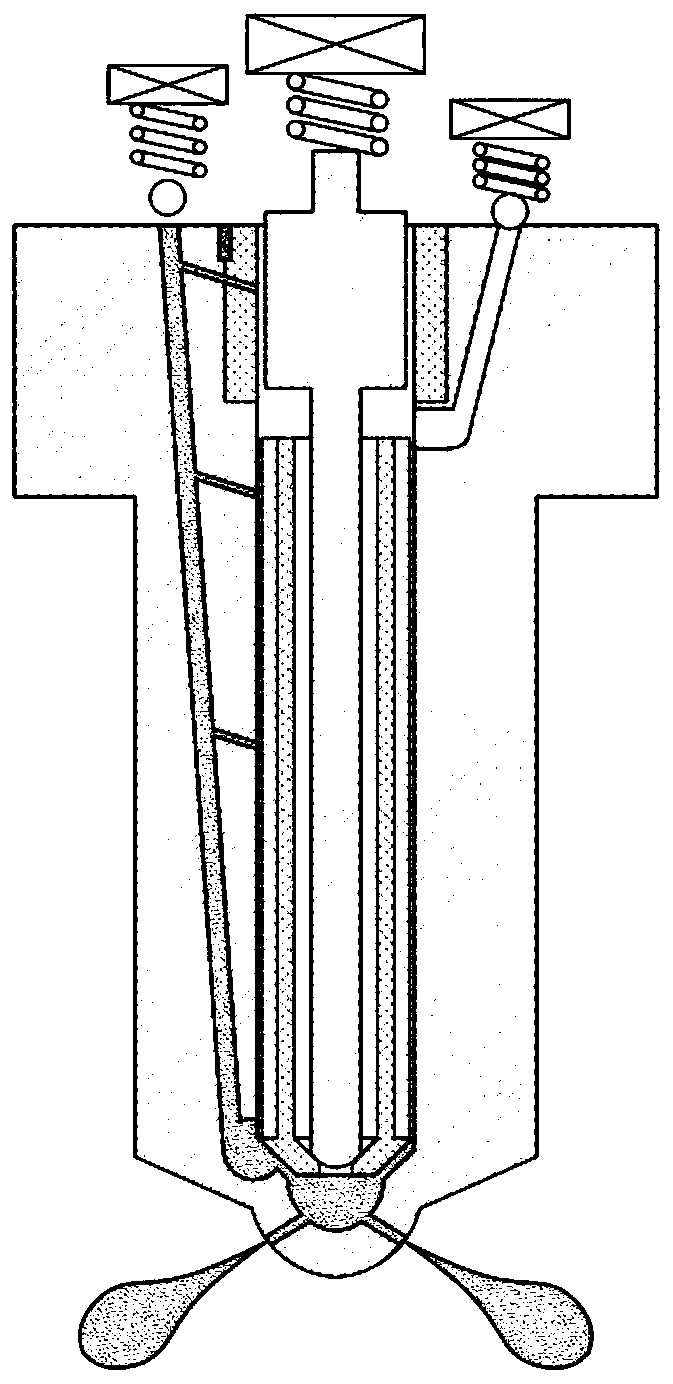

[0043] Such as Figure 1-3As shown, this embodiment provides a nozzle for a dual-fuel engine, including a nozzle body, a solenoid valve, a positioning pin, an insulating sleeve, a needle valve electrode, an insulating needle valve, and a grounding electrode; the nozzle body is the main structure and is used to carry other Each component and structure, and realize fuel injection, on described nozzle body, be processed with natural gas fuel channel 13, diesel fuel channel 12 and three lubricating holes 11; Described natural gas fuel channel 13 is used for introducing natural gas, and described diesel fuel channel For introducing diesel oil, the uppermost lubricating hole 11 is used to introduce a small amount of diesel oil from the diesel fuel passage 12 between the needle valve electrode 7 and the insulating sleeve 6, and the lower two lubricating holes are used to introduce a small amount of diesel oil from the diesel fuel passage 12. The channel is introduced between the oute...

Embodiment 2

[0047] Such as Figure 4 As shown, the present embodiment provides a diesel and natural gas dual-fuel engine nozzle working method, the specific steps are:

[0048] (1) In the nth cycle, the crankshaft position sensor judges the crankshaft position. If the current crankshaft angle has not reached the set value, continue to judge; if it has reached the set value, the ECU outputs a lifting command to the solenoid valve b4. The time is recorded as the time origin t.

[0049] (2) The solenoid valve b4 is lifted, and the natural gas enters the natural gas fuel channel 13 through the fuel supply pipeline.

[0050] (3) Taking the time origin t as the starting point, after the calibrated Δt1 time interval (Δt1 is the time from the time origin t to the time when the natural gas is about to enter the ionization space 16), the ECU issues an instruction to power the needle valve electrode 7 Power supply with higher voltage U (for example: 15 ~ 20kV).

[0051] (4) Dielectric barrier dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com