Dual-wall screw well drilling system based on gas-liquid two-phase drive

A gas-liquid and drilling technology, which is applied in liquid/gas jet drilling, drilling equipment, directional drilling, etc. It can solve the problems that affect the rock-breaking drilling of the drill bit, slow down the drilling speed of the drill bit, and reduce the pressure difference between the inlet and outlet of the motor. To achieve the effect of prolonging continuous operation capability, increasing drilling speed and reducing holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

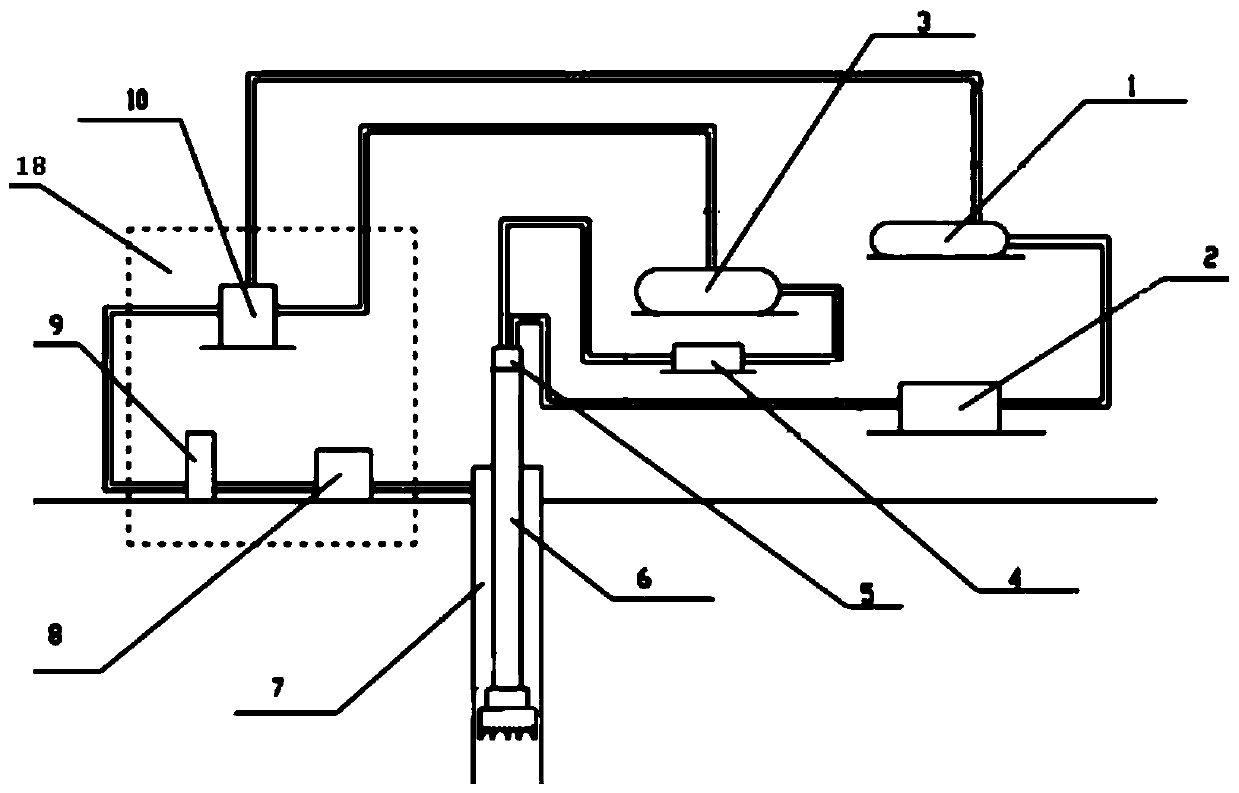

[0038] like figure 1 As shown, the double-wall screw drilling system based on gas-liquid two-phase drive includes surface system, wellhead device 5 and downhole drilling tool assembly 6;

[0039] The ground system includes a gas storage tank 1 and a liquid storage tank 3. The gas storage tank 1 and the liquid storage tank 3 communicate with the wellhead device 5 through an air compressor 2 and a liquid high-pressure pump 4 respectively. The gas storage tank 1 and the liquid storage tank 3 are also connected with the gas-liquid two-phase flow recovery device 18; the gas-liquid two-phase flow recovery treatment device 18 includes a desander 8 connected with the wellbore annulus 7, and the desander 8 is connected with The back pressure valve 9 and the ground gas-liquid separation device 10, wherein the gas outlet of the ground gas-liquid separation device 10 is connected to the gas storage tank 1, and the liquid outlet of the ground gas-liquid separation device 10 is connected to...

Embodiment 2

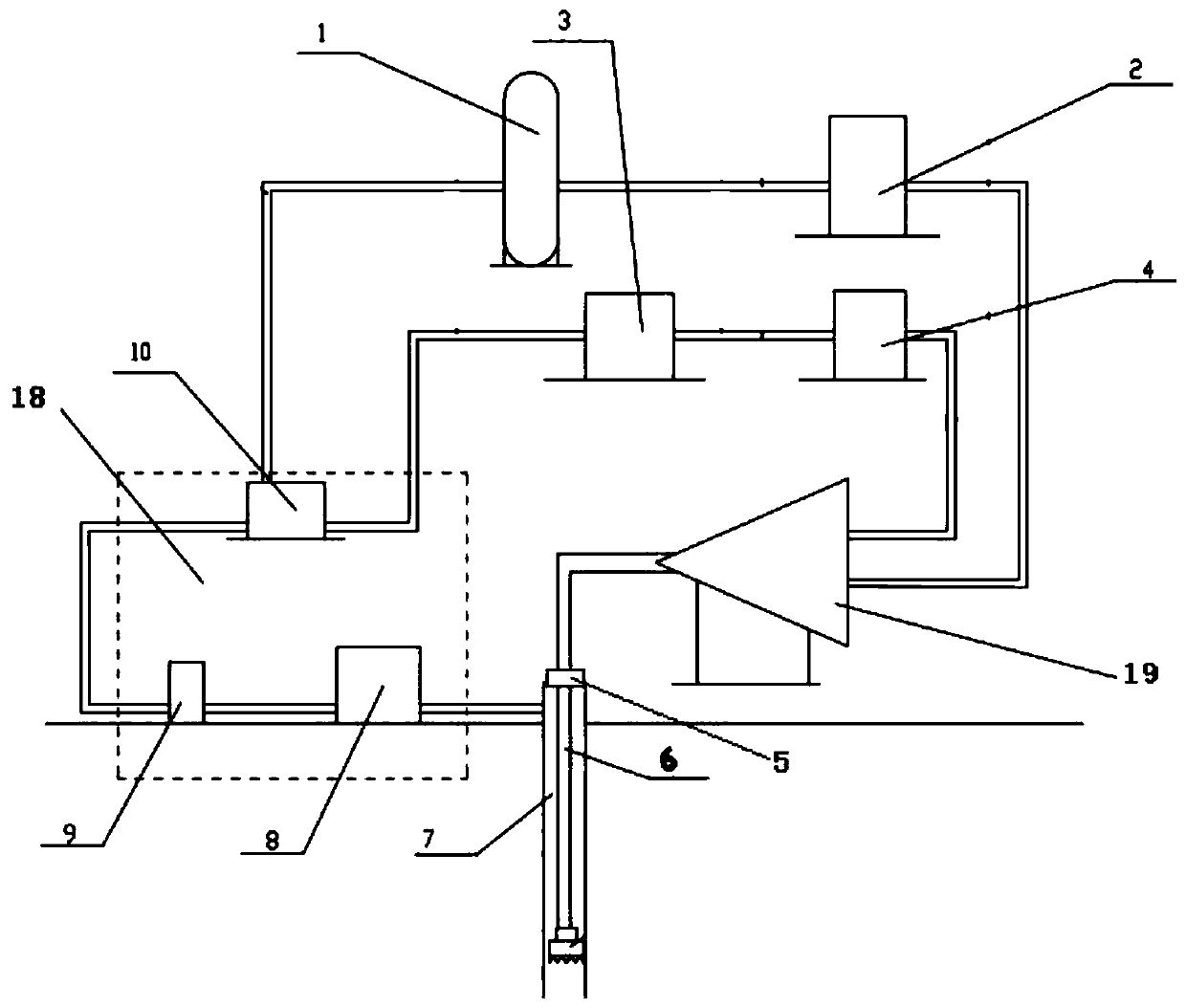

[0048] like figure 2 As shown, the double-wall screw drilling system based on gas-liquid two-phase drive includes surface system, wellhead device 5 and downhole drilling tool assembly 6;

[0049] The ground system includes a gas storage tank 1 and a liquid storage tank 3, the gas storage tank 1 and the liquid storage tank 3 are respectively connected to a gas-liquid mixing device 19 through an air compressor 2 and a liquid high-pressure pump 4, and the gas-liquid mixing The device 19 is in communication with the wellhead device 5; the gas storage tank 1 and the liquid storage tank 3 are also respectively connected with the gas-liquid two-phase flow recovery device 18, and the gas-liquid two-phase flow recovery treatment device 18 includes a The connected desander 8 is sequentially connected with a back pressure valve 9 and a ground gas-liquid separation device 10, wherein the gas outlet of the ground gas-liquid separation device 10 is connected to the gas storage tank 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com