Steel for automobile engine connecting rod as well as manufacturing method thereof

A technology of automobile engine and manufacturing method, which is applied in the field of metallurgical manufacturing, can solve the problems of difficult stable control of tensile strength, crack source, and reduced service life of connecting rods, etc., and achieve the effect of good surface quality, low sulfide level, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described.

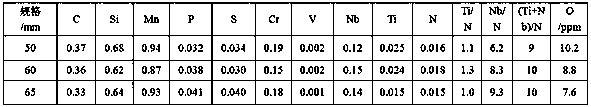

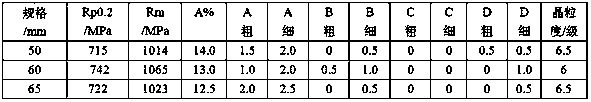

[0016] A kind of steel for automobile engine connecting rod and its manufacturing method, its composition and weight percentage (Wt%) are: C: 0.32%-0.40%, Si: 0.40%-0.70%, Mn: 0.80%-0.95%, S : 0.025%-0.040%, P: 0.030%-0.045%, Cr: 0.10%-0.20%, Mo≤0.10%, Nb: 0.08-0.20%, Ti: 0.015%-0.035%, Ni≤0.10%, N: 0.012-0.020%; O≤15×10 -6 , the rest is Fe and unavoidable impurities.

[0017] The main chemical composition design (mass percentage) of the steel for the connecting rod of the present invention.

[0018] C: 0.32-0.40%. C is an essential component to ensure the strength of connecting rod steel. If the C content is too low, the strength of the steel for the connecting rod is not enough, and it cannot guarantee good low toughness and improve the fracture property. Therefore, the present invention determines that the C content is 0.32-0.40%, more preferably, the C content is 0.34-0.39%.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com