A kind of button with cotton and linen effect and preparation method thereof

A button, cotton and linen technology, applied in the field of clothing accessories, can solve problems such as not seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

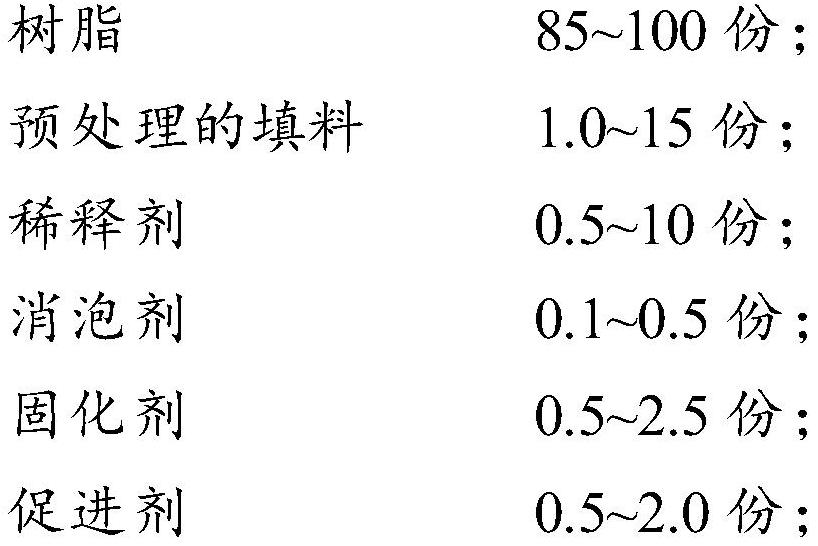

[0080] The present invention also provides a method for preparing a button with cotton and linen effect described in the above technical scheme, comprising the following steps:

[0081] a) mixing resin, pretreated filler, diluent, defoaming agent, curing agent and accelerator to obtain blanking slurry;

[0082] b) solidifying the blank-making slurry to obtain a button blank;

[0083] c) subjecting the button blank to button making and polishing to obtain a finished button;

[0084] d) dyeing the finished button to obtain a button with cotton and linen effect.

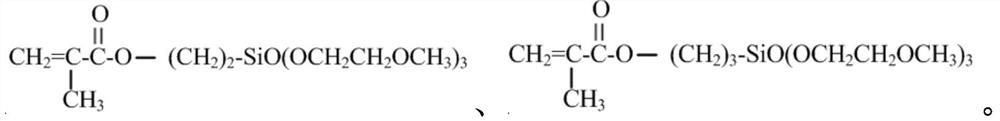

[0085] In the step a), the types, amounts and sources of the resins, pretreated fillers, diluents, defoamers, curing agents and accelerators are all consistent with those described in the above technical solutions, and will not be repeated here. One more elaboration. The mixing method is not particularly limited, and the raw materials can be mixed uniformly according to the conventional mixing methods well known to t...

Embodiment 1

[0092] 1.1 Preparation of buttons

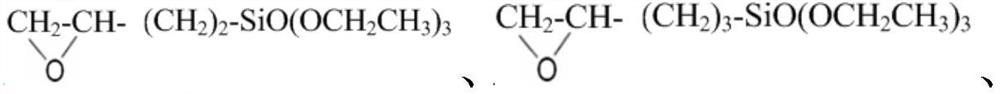

[0093] S1: add 10% milk ferment filler to the pretreatment agent aqueous solution with a concentration of 5%, stir at 10 rpm for 80 min, and place it in an oven at 80°C for 3 hours to dry to obtain the pretreated filler;

[0094] The pretreatment agent used was: NH 2 -(CH 2 ) 2 -SiOCl 3 .

[0095]S2: Add 15 parts of pretreated filler to 90 parts of unsaturated resin, add 10 parts of styrene diluent, 0.2 part of defoamer, 1.0 part of cobalt naphthenate accelerator, mix well, and then add methyl ethyl ketone peroxide to cure Add 1.5 parts of the agent, stir and pour it into a rotating centrifuge, use centrifugal action to distribute the mixed slurry in the radial direction of the centrifuge, and solidify and form on the surface of the centrifuge to obtain a plate. The obtained plate is punched in sequence to obtain a blank, and then the blank is cut on a button making machine to obtain a blank of a desired shape, and finally polished to o...

Embodiment 2

[0105] 1.1 Preparation of buttons

[0106] S1: add 15% milk ferment filler to the pretreatment agent aqueous solution with a concentration of 10%, stir at 10 rpm for 80 min, and place it in an oven at 80°C to dry for 3 hours to obtain the pretreated filler;

[0107] The pretreatment agent used was: NH 2 -(CH 2 ) 3 -SiOCl 3 .

[0108] S2: Add 10 parts of pretreated fillers to 90 parts of epoxy resin, and add 5 parts of propylene oxide allyl ether diluent, 0.3 part of defoamer, 1.0 part of cobalt isooctanoate accelerator, mix evenly, and then add fatty amine 2.0 parts of a curing agent, pour the obtained mixed slurry into a plastic mold, and cure to obtain a pre-shaped body. The predetermined shaped body is punched in sequence to obtain a blank, and then the blank is cut on a button making machine to obtain a blank of a desired shape, and finally polished to obtain a finished button.

[0109] S3: The obtained finished button is dyed, and the dye solution includes:

[0110...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com