Efficient precipitation device and process with ammonia nitrogen removal capacity

A high-efficiency precipitation, ammonia nitrogen technology, applied in water/sewage multi-stage treatment, water pollutants, centrifugal separation of water/sewage treatment and other directions, can solve the problems of ammonia nitrogen harm, low removal efficiency, etc. The effect of reducing economic cost and reducing purchase cost agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

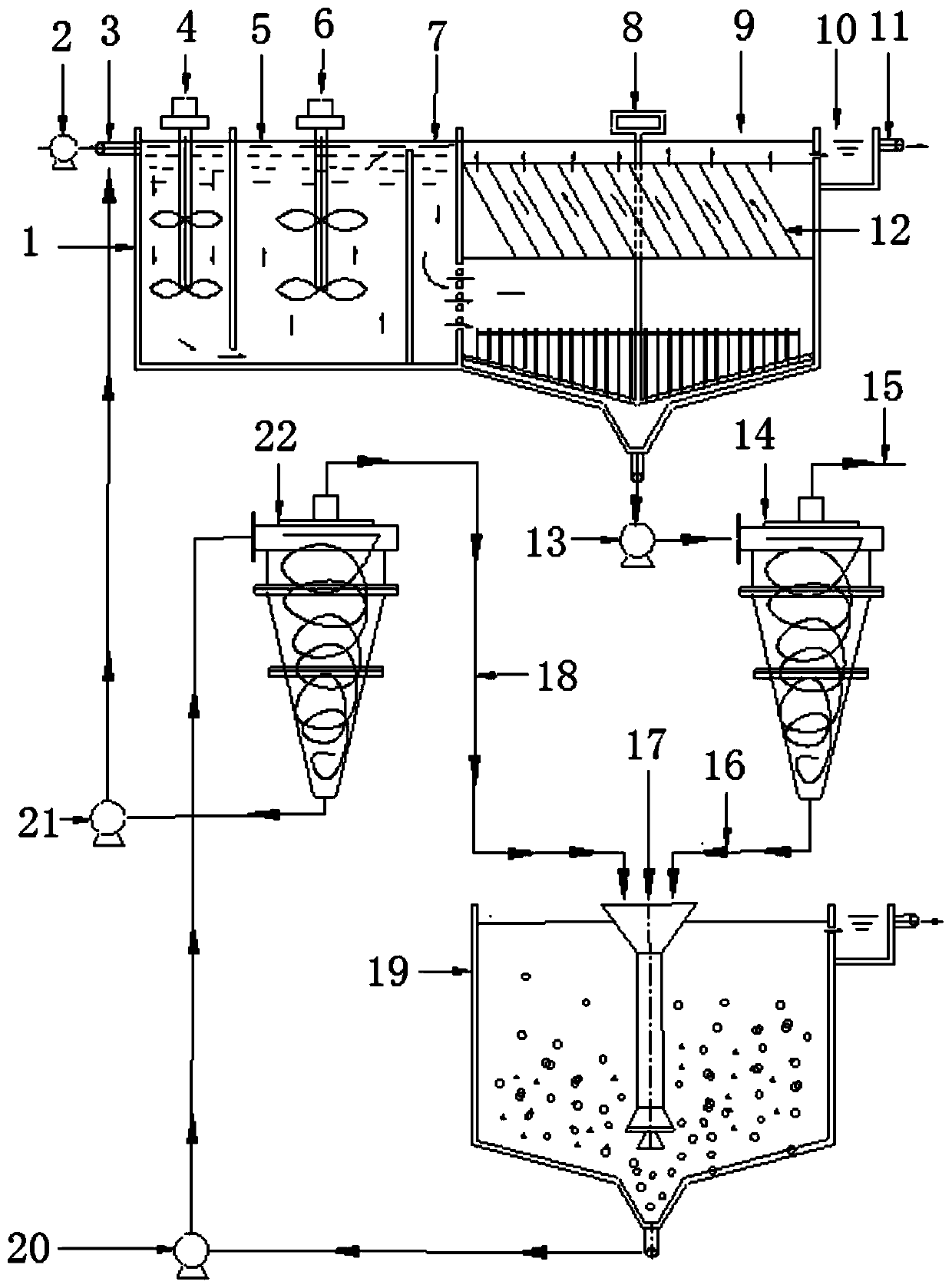

[0069] This embodiment provides a high-efficiency precipitation technology with ammonia nitrogen removal capacity with reference to any of the above-mentioned implementation modes, and its process flow can be found in figure 1 As shown, the main equipment includes coagulation tank, flocculation tank, inclined plate sedimentation tank, sludge separator, regeneration tank and sand-water separator.

[0070] The specific steps of the high-efficiency precipitation technology with ammonia nitrogen removal ability to treat wastewater in this embodiment are as follows:

[0071] The waste water to be treated is sent into the water inlet pipe through the water inlet pump, and the upper part of the water inlet pipe is provided with a dosing port for adding coagulant and ammonia nitrogen adsorption material; the coagulant and ammonia nitrogen adsorption material enter the water inlet pipe through the dosing port to fully mix with the waste water, and then Enter the coagulation tank, and q...

Embodiment 2

[0074]Rainwater from a rainwater pumping station in Shanghai has SS concentration of 540mg / L, ammonia nitrogen concentration of 7-9mg / L, total phosphorus concentration of 1.21-1.46mg / L, and COD concentration of 160-200mg / L. After the technical treatment of Example 1 , SS, ammonia nitrogen, total phosphorus and COD removal rates were 99.6%, 91.2%, 99.8%, 85.7%. After analysis, the cost of water treatment chemicals per ton is 0.04-0.12 yuan.

[0075] In this example, the coagulant used is a composite composition of 0.50 g Fe / L ferric chloride and 1.10 g / L polyaluminum sulfochloride.

[0076] The ammonia nitrogen adsorption material used is zeolite, and its dosage at the coagulation tank is 2g / L.

[0077] The stirring speed of the coagulation treatment is 400rpm, and the hydraulic retention time is 100s.

[0078] The stirring speed of the flocculation treatment is 80rpm, and the hydraulic retention time is 5min.

[0079] The hydraulic retention time of the inclined plate sedim...

Embodiment 3

[0083] The raw water of a water purification plant belongs to the type of low temperature, low turbidity and high algae content, which is difficult to treat. The original sedimentation tank was changed to the high-efficiency sedimentation system as in Example 1 through process transformation, which saves the tank volume for the front-end treatment of ammonia nitrogen and achieves a good water purification effect. After the transformation, the algae removal rate reaches more than 95%, and the turbidity removal The rate reached 99.8%.

[0084] In this embodiment, the coagulant used is 0.03 g / L polyaluminum ferric chloride.

[0085] The ammonia nitrogen adsorption material used is zeolite, and the dosage at the coagulation tank is 1.0g / L.

[0086] The stirring speed of the coagulation treatment is 400rpm, and the hydraulic retention time is 150s.

[0087] The stirring speed of the flocculation treatment is 60rpm, and the hydraulic retention time is 8min.

[0088] The hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com