Hollow annular tungsten electrode GTA array wire filling additive manufacturing method and device

A technology of additive manufacturing and tungsten electrode, which is applied in the field of additive manufacturing of hollow annular tungsten electrode GTA array wire filling, which can solve the problems of poor stability of arc pressure molten pool and low stacking efficiency, so as to enhance coaxiality and improve stacking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The test platform of this embodiment is as follows: the GTA wire-filling additive manufacturing power supply is Fronius MW300, the wire feeder model is KD4010, the motion actuator is a MOTOMAN robot, the GTA gun is fixed on the end of the sixth axis of the MOTOMAN robot through a clamp, and the robot controls GTA movement. The substrate size is 300mm×200mm×6mm.

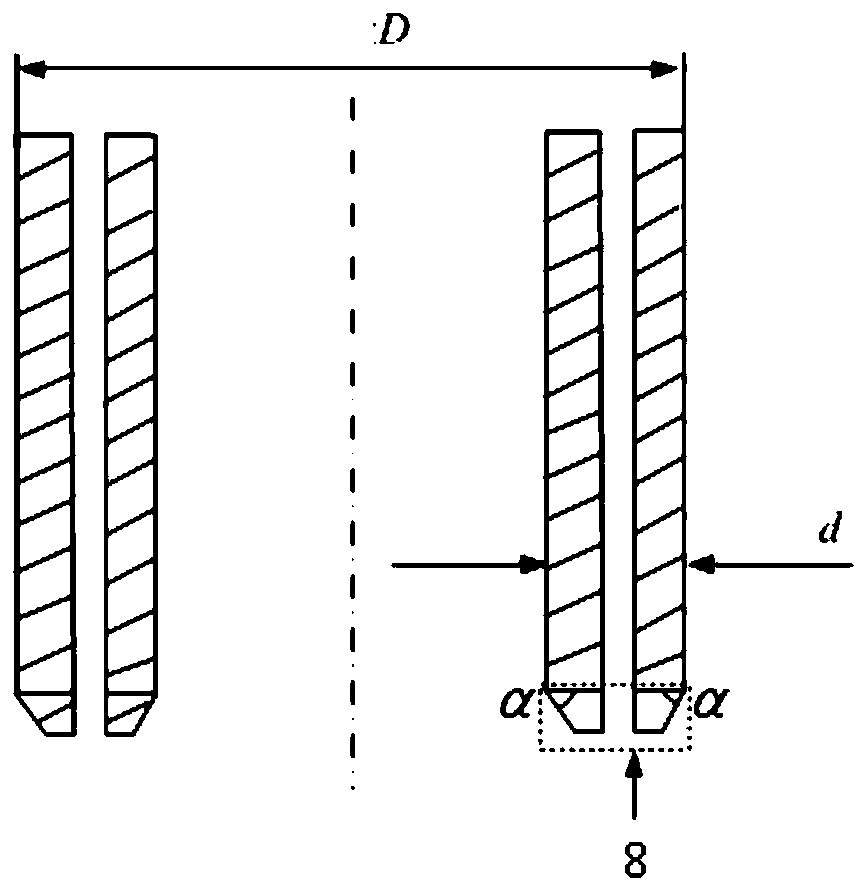

[0033] A hollow annular tungsten electrode GTA array wire-filled additive manufacturing method, using a hollow annular tungsten electrode, the wall thickness d between the outer surface and the inner surface of the hollow annular tungsten electrode is 1.0-4.0mm, the annular tungsten electrode The outer diameter D is 3-10mm, and the outer surface and the bottom of the inner surface of the annular tungsten electrode are provided with a chamfer α, and the value range of α is 30-60°, and the surface of the tungsten electrode between the chamfers forms a circular platform, The circular platform is used to limit the...

Embodiment 2

[0039] This embodiment provides a hollow annular tungsten electrode GTA array filling wire additive manufacturing device,

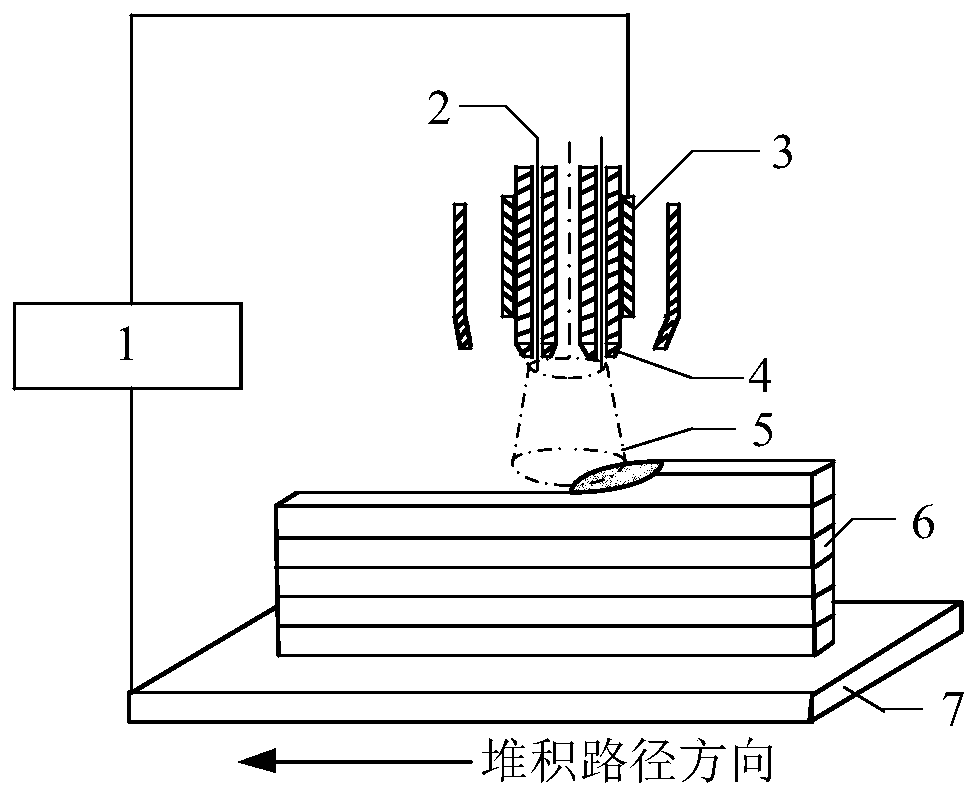

[0040] Including GTA power supply 1, metal wire 2, electrode clamp 3, hollow annular tungsten electrode 4, arc 5, accumulation layer 6, substrate 7, the positive pole of the GTA power supply 1 is connected to the substrate 7, the negative pole of the GTA power supply 1 is connected to the electrode clamp 3 connection, the outer surface of the hollow annular tungsten electrode 4 cooperates with the electrode holder 3, and the arc 5 is established between the hollow annular tungsten electrode 4 and the accumulation layer;

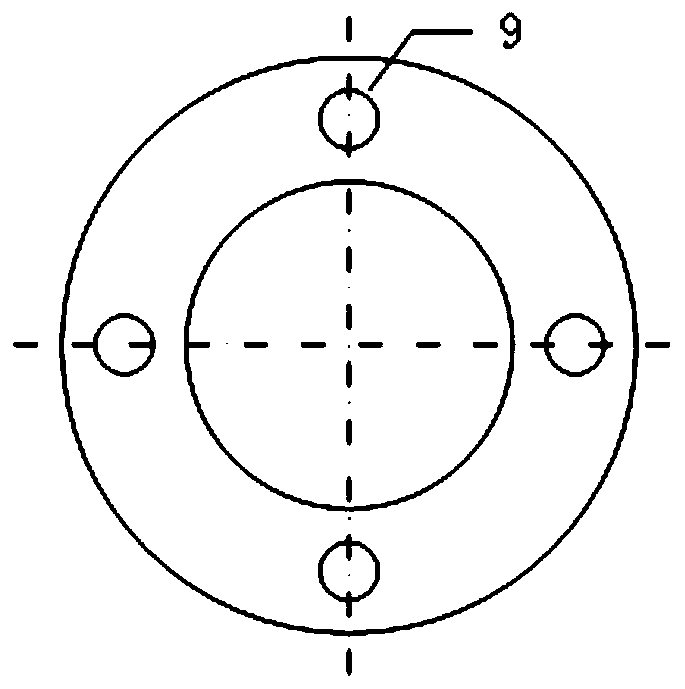

[0041] The wall thickness d between the outer surface and the inner surface of the hollow ring-shaped tungsten electrode is 1.0-4.0mm, the outer diameter D of the ring-shaped tungsten electrode is 3-10mm, and the outer surface and the bottom of the inner surface of the ring-shaped tungsten electrode are both set There is a chamfer α, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com