Method for rapidly producing transfer factors

A transfer factor and rapid technology, applied in chemical instruments and methods, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve problems such as complex method steps, and achieve the effects of simple reagents, strong practicability, and sufficient cell disruption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

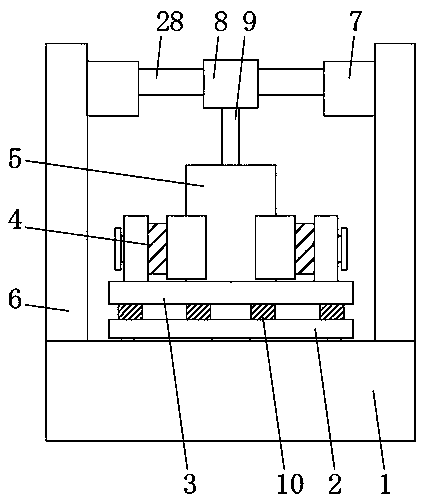

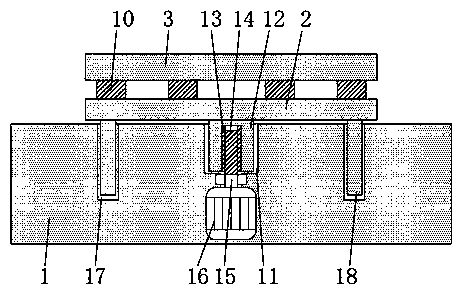

Image

Examples

Embodiment 1

[0040] A method for rapidly producing transfer factor, comprising the steps of:

[0041] 1) Take fresh pig spleen, wash it, remove fat and film, weigh it after crushing, add distilled water, the amount of distilled water is twice the weight of pig spleen;

[0042] 2) Add the pig spleen and distilled water in step 1) into a masher, and the conditions for mashing are: 8000rpm, homogenate for 5min;

[0043] 3) Add collagenase I to the slurry obtained in step 2), and act at 18°C for 2 hours;

[0044] 4) Adjust the pH of the slurry to 5.0 with 1mol / L hydrochloric acid, act at 18°C for 4 hours, then adjust the pH of the slurry to 8.0 with 1mol / L sodium hydroxide solution, and act at 18°C for 6 hours;

[0045] 5) Use 1mol / L hydrochloric acid to adjust the pH of the slurry to 6.5, ultrasonically crush for 15 minutes, and repeat once every 5 minutes; when ultrasonically crushing, the power of the ultrasonic wave is 19.5KHz, and the temperature is 8°C;

[0046] 6) Centrifuge the...

Embodiment 2

[0049] A method for rapidly producing transfer factor, comprising the steps of:

[0050] 1) Take fresh pig spleen, wash it, remove fat and film, weigh it after crushing, add distilled water, the amount of distilled water is 3 times the weight of pig spleen;

[0051] 2) Add the pig spleen and distilled water in step 1) into the masher, and the conditions for mashing are: 10000rpm, homogenate for 3min;

[0052]3) Add collagenase I to the slurry obtained in step 2), and act at 25°C for 1 hour;

[0053] 4) Use 1mol / L hydrochloric acid to adjust the pH of the slurry to 6.0, act at 25°C for 2h, then use 1mol / L sodium hydroxide solution to adjust the pH of the slurry to 9.0, and act at 25°C for 3h;

[0054] 5) Use 1mol / L hydrochloric acid to adjust the pH of the slurry to 7.2, ultrasonically crush for 30 minutes, and repeat once every 10 minutes; when ultrasonically crushing, the power of the ultrasonic wave is 20.5 KHz, and the temperature is 2°C;

[0055] 6) Centrifuge the slurry...

Embodiment 3

[0058] A method for rapidly producing transfer factor, comprising the steps of:

[0059] 1) Take fresh pig spleen, wash it, remove fat and film, weigh it after crushing, add distilled water, the amount of distilled water is twice the weight of pig spleen;

[0060] 2) Add the pig spleen and distilled water in step 1) into the mashing machine, the conditions for mashing are: 9000rpm, homogenization for 4min;

[0061] 3) Add collagenase I to the slurry obtained in step 2), and act at 20°C for 2 hours;

[0062] 4) Adjust the pH of the slurry to 6.0 with 1mol / L hydrochloric acid, act at 20°C for 3h, then adjust the pH of the slurry to 9.0 with 1mol / L sodium hydroxide solution, and act at 20°C for 5h;

[0063] 5) Use 1mol / L hydrochloric acid to adjust the pH of the slurry to 7.0, ultrasonically crush for 20 minutes, and repeat once at an interval of 8 minutes; when ultrasonically crushing, the power of the ultrasonic wave is 20KHz, and the temperature is 5°C;

[0064] 6) Centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com