Soybean milk powder which does not cause abdominal distension and preparation method thereof

A production method and technology of soybean milk powder, which are applied in the field of food processing, can solve the problems of high price of α-galactosidase preparation, unfavorable industrial production and application, etc., and achieve the effects of low production cost and complete biodegradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

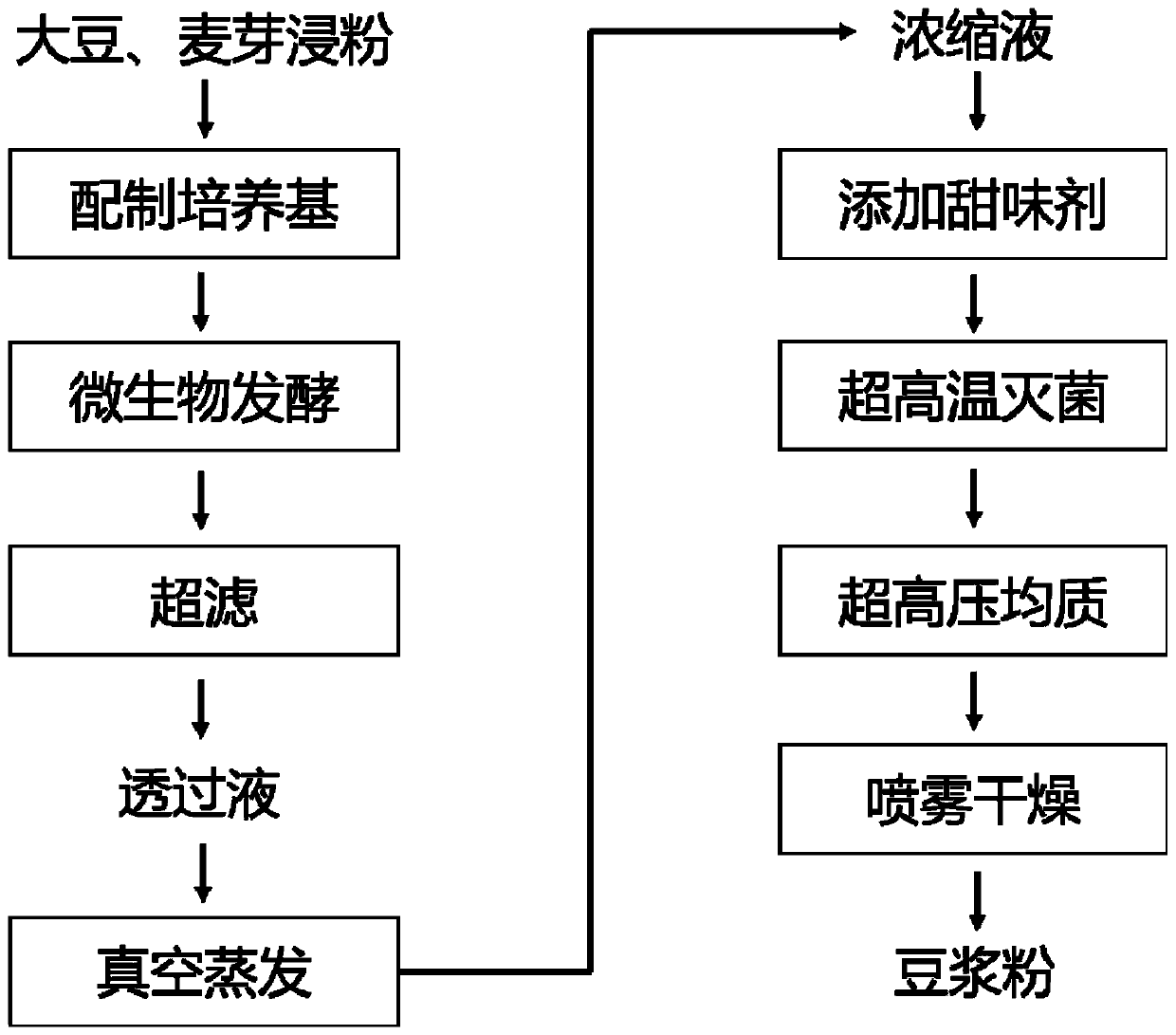

[0057] A kind of manufacturing project of soybean milk powder that does not cause abdominal distension, such as figure 1 As shown, the specific description is as follows:

[0058] (1) Preparation of soybean milk medium

[0059] Weigh 2 kg of soybeans, soak them in water for 7 hours, remove the skins, and drain the water. Put the dehulled soybeans into a beater, add 0.8kg of food-grade wort extract powder, add 24L of purified water, and beat under the condition of 7000r / min. Filter with a 200-mesh sieve, take the liquid under the sieve, and obtain 28.2L soybean milk culture medium. Put the soymilk medium into the fermenter, adjust the pH to 6.5, sterilize at 121°C for 12 minutes, cool down and set aside.

[0060] (2) Fermentation and decomposition of soybean oligosaccharides

[0061] Weigh 90g of food-grade malt extract powder, add 1800mL of water, stir to dissolve, adjust the pH to 6.5, and prepare it as a yeast culture medium. Divide the yeast culture medium into nine 1000...

Embodiment 2

[0066] (1) Preparation of soybean milk medium

[0067] Weigh 2.5kg of soybeans, soak the soybeans in water for 6 hours, remove the bean skins, and drain the water. Put the dehulled soybeans into a beater, add 0.75kg of food-grade wort extract powder, add 25L of pure water, and beat under the condition of 8000r / min. Filter with a 200-mesh sieve, take the liquid under the sieve, and obtain 30.8L soybean milk medium. Put the soymilk medium into the fermenter, adjust the pH to 6.0, sterilize at 121°C for 10 minutes, cool down and set aside.

[0068] (2) Fermentation and decomposition of soybean oligosaccharides

[0069] Weigh 44.4g of food-grade malt extract powder, add 800mL of water, stir to dissolve, adjust the pH to 6.0, and prepare it as a yeast culture medium. Divide the yeast culture medium into four 1000mL Erlenmeyer flasks, the volume of each bottle is 200mL, sterilize at 121°C for 15 minutes, after cooling, insert 1 loop (inoculation loop) of Kluyveromyces lactis CICC...

Embodiment 3

[0074] (1) Preparation of soybean milk medium

[0075] Weigh 2.5kg of soybeans, soak them in water for 8 hours, remove the bean skins, and drain the water. Put the dehulled soybeans into a beater, add 1.25kg of food-grade wort extract powder, add 35L of pure water, and beat under the condition of 6000r / min. Filter with a 200-mesh sieve, take the liquid under the sieve, and obtain 40.6L soybean milk culture medium. Put the soymilk medium into the fermenter, adjust the pH to 7.0, sterilize at 121°C for 15 minutes, cool down and set aside.

[0076] (2) Fermentation and decomposition of soybean oligosaccharides

[0077] Weigh 190.9g of food-grade malt extract powder, add 4200mL of water, stir to dissolve, adjust the pH to 7.0, and prepare it as a yeast culture medium. Divide the yeast culture medium into 21 1000mL Erlenmeyer flasks, the volume of each bottle is 200mL, sterilize at 121°C for 15 minutes, after cooling, insert 1 loop (inoculation loop) of Kluyveromyces lactis CICC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com