Display panel and manufacturing method thereof

A technology for display panels and manufacturing methods, applied in semiconductor/solid-state device manufacturing, instruments, optics, etc., can solve problems such as cracking or breaking of metal electrodes, and achieve the effect of avoiding cracks or breaks and not being easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., are only appended The directions in the drawings and the direction terms used herein are used to explain and illustrate the present invention, rather than to limit the protection scope of the present invention.

[0039] In addition, it should also be noted that in some alternative implementations, the steps of all methods described herein may occur out of order. For example, two steps shown in succession may, in fact, be executed substantially concurrently, or the two steps may sometimes be executed in the reverse order.

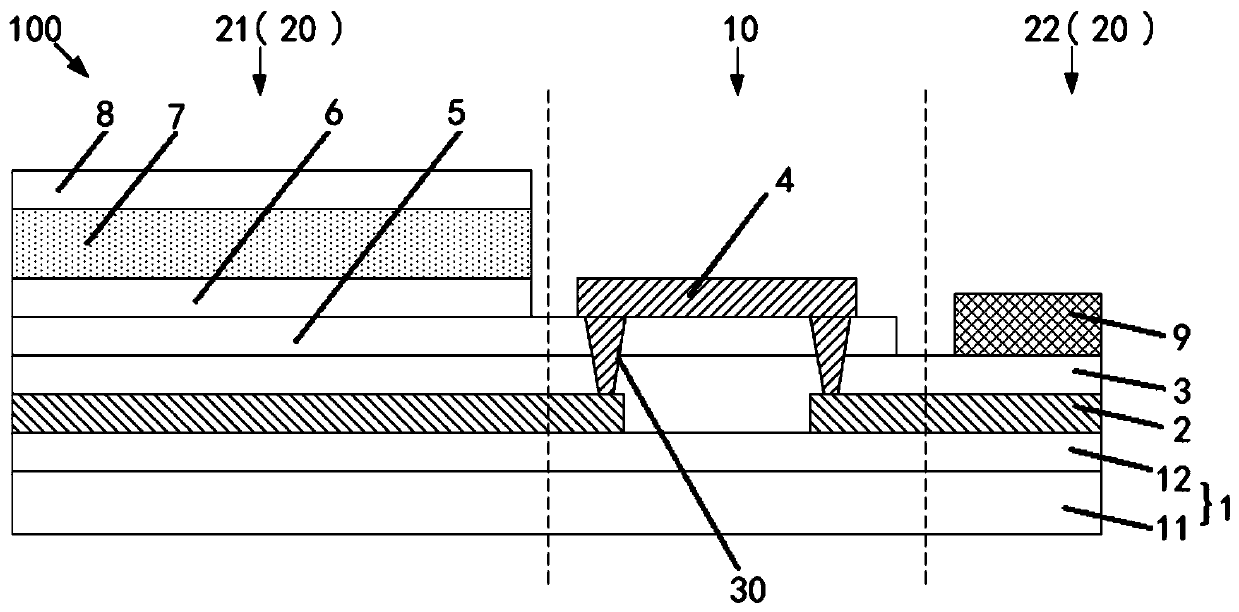

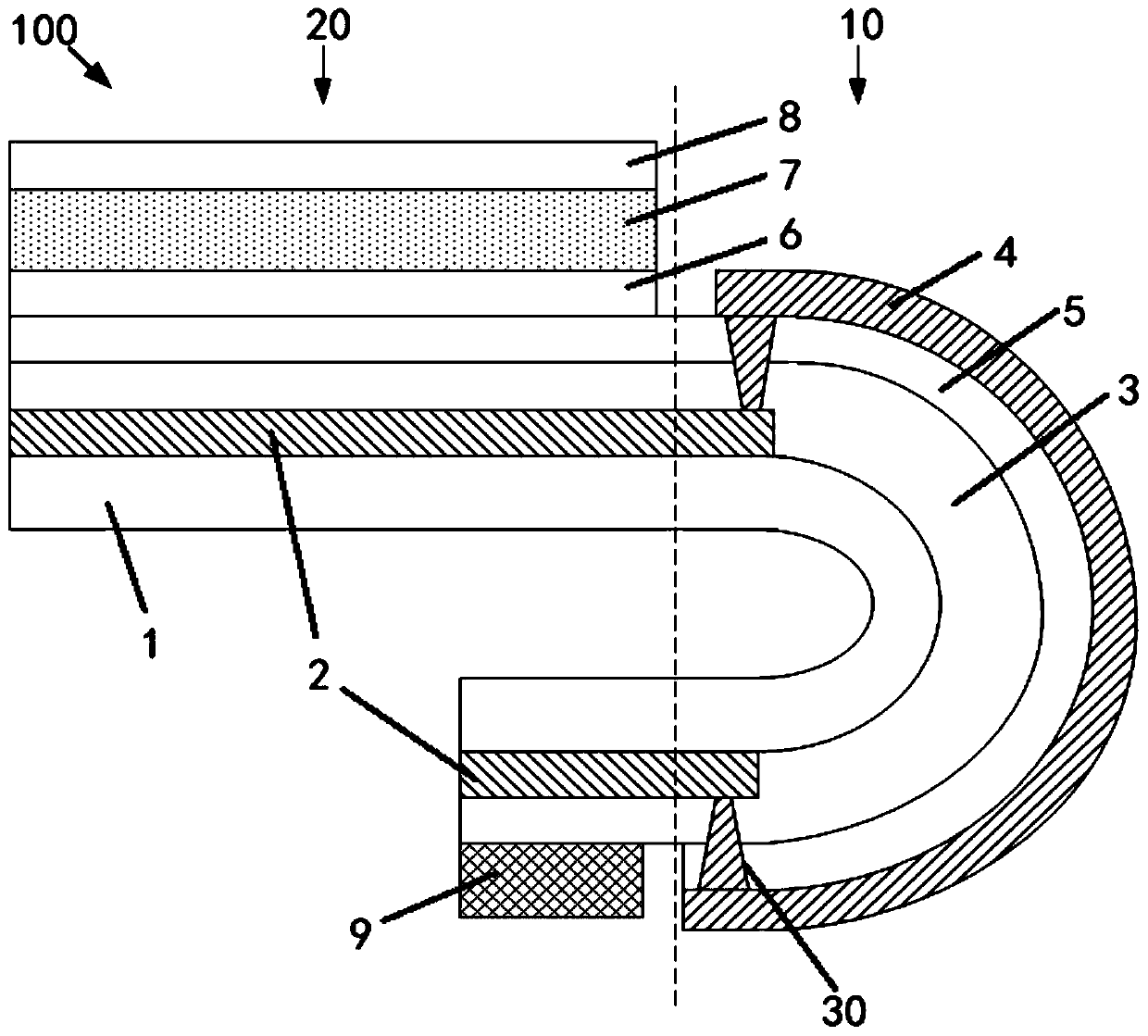

[0040] see figure 1 , figure 2 As shown, one embodiment of the present invention provides a display panel 100, which defines a bending area 10 and non-bending areas 20 located on both sides of the bending area 10, and the non-bending area 20 includes The displayed display area 21 and the binding area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com