Online monitoring method for exhaust steam dryness of low-pressure cylinder of steam turbine

A low-pressure cylinder and steam turbine technology, applied in the field of on-line monitoring of steam turbine low-pressure cylinder exhaust steam quality, can solve the problems of difficult accurate determination of reference flow, pressure and temperature, complicated calculation process, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

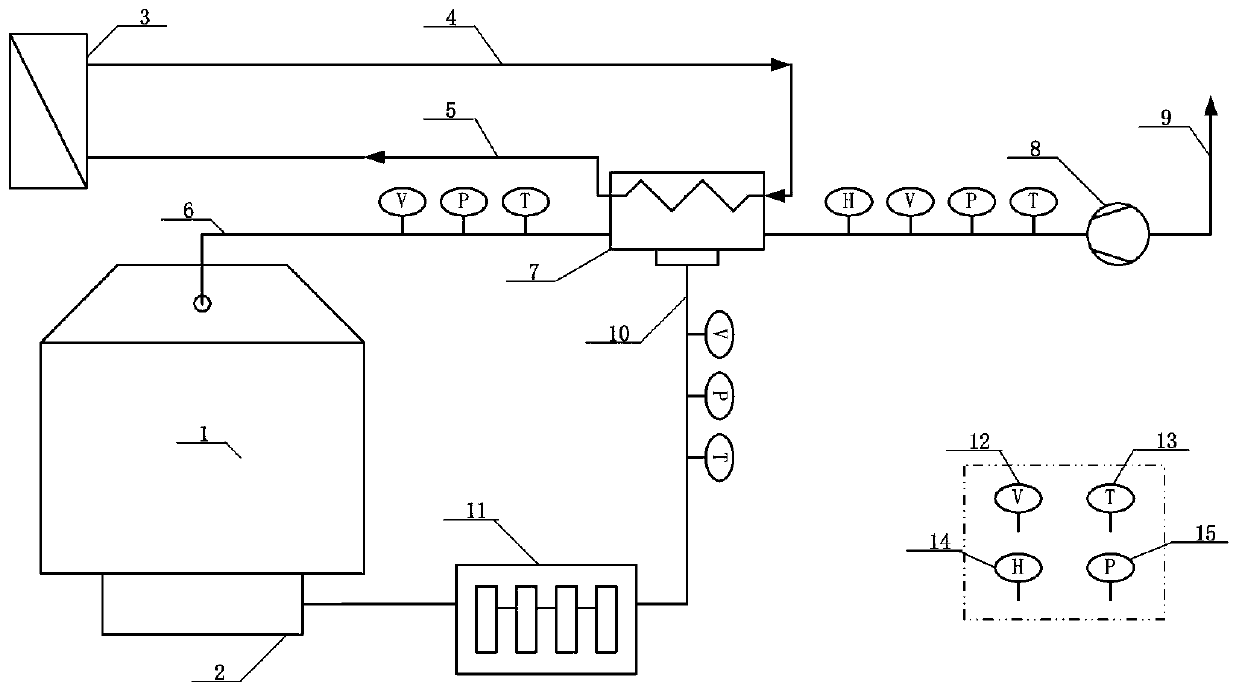

[0081] like figure 1 As shown in the present invention, the on-line monitoring method for the dryness of the steam exhausted from the low-pressure cylinder of a steam turbine, the monitoring system used in the method includes a condenser 7, a vacuum pump 8 and a refrigerator 3. The air-side inlet of condenser 7 enters condenser 7, and then the air-side outlet of condenser 7 and vacuum pump 8 are discharged to the atmosphere through vacuum pump exhaust line 9; the cooling medium in condenser 7 comes from refrigerator 3, condenser 7 The refrigerant inlet and refrigerant outlet are connected to the outlet and inlet of the refrigerator 3 respectively. The refrigerant generated by the refrigerator 3 enters the condenser 7 through the refrigerant outlet pipeline, and after absorbing heat in the condenser 7, it returns to the refrigerator 3 through the refrigerant inlet pipeline to continue. Refrigeration, forming a closed loop.

[0082] The drain port of the condenser 7 is connecte...

Embodiment 2

[0138] The selection design of this embodiment is that due to the large cross-sectional area of the steam exhaust port of the low-pressure cylinder of the steam turbine, the flow field is a non-uniform flow field, so it is difficult to reflect the real exhaust steam dryness only through one steam extraction pipeline. Therefore, in this embodiment, there are multiple steam extraction pipelines between the condenser and the condenser, and the suction port of each steam extraction pipeline is inserted into the throat of the condenser. They are all inclined at an angle of 30° to 60°.

[0139] In this embodiment, the number of steam extraction pipes can be determined according to the cross-sectional area of the condenser throat 16, which can generally be controlled at 1.5m 2 ~3m 2 Arrange one steam extraction line. In principle, the more steam extraction lines are arranged in the condenser throat 16, the more accurate the exhaust steam dryness of the low-pressure cylinder of t...

Embodiment 3

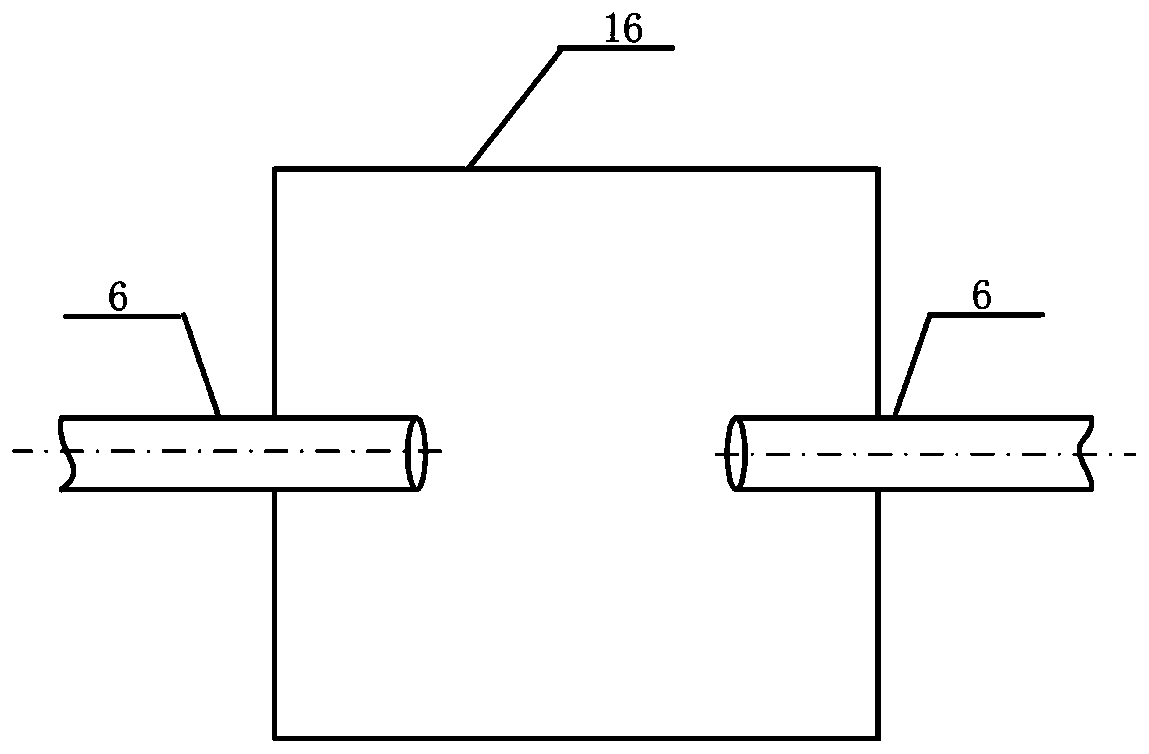

[0141] The selection design of this embodiment is: in this embodiment, the number of multi-channel steam extraction pipelines is 4, such as Figure 4 As shown, the suction ports of the 4-way steam extraction pipelines are respectively inserted from the periphery (middle) of the condenser throat 16, and the lengths of the 4-way insertion are equivalent, and the inclination angles between the 4-way steam extraction pipelines are all 45° from the horizontal plane. The 4 steam extraction pipes are combined into one steam extraction main pipe and monitored by a monitoring system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com