Multifunctional integrated 3D printing building enclosure wall

A 3D printing and building envelope technology, applied in the field of 3D printing, can solve the problems of time-consuming, loss of rapid prototyping, etc., and achieve the effects of improving weather resistance, reducing manufacturing time, and meeting aesthetic needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

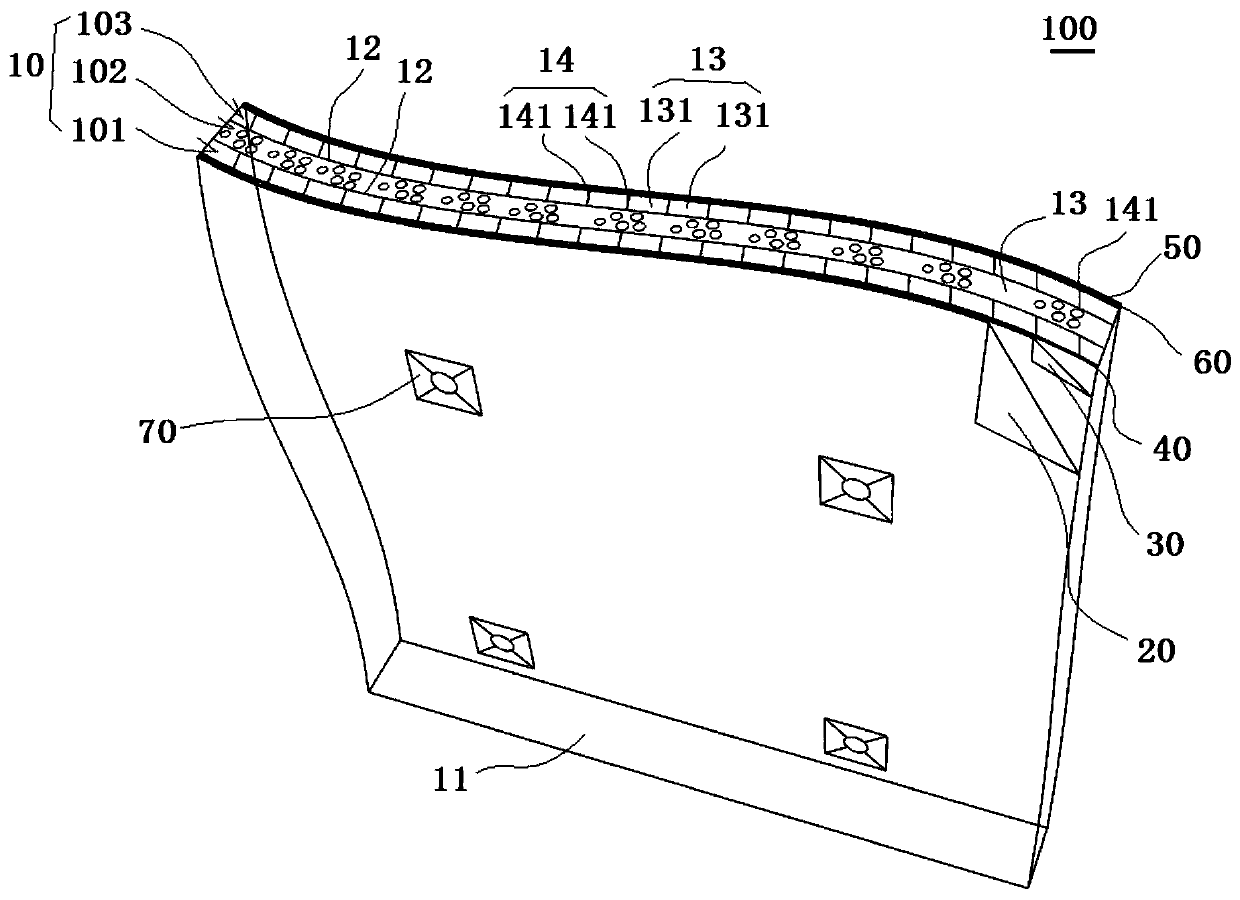

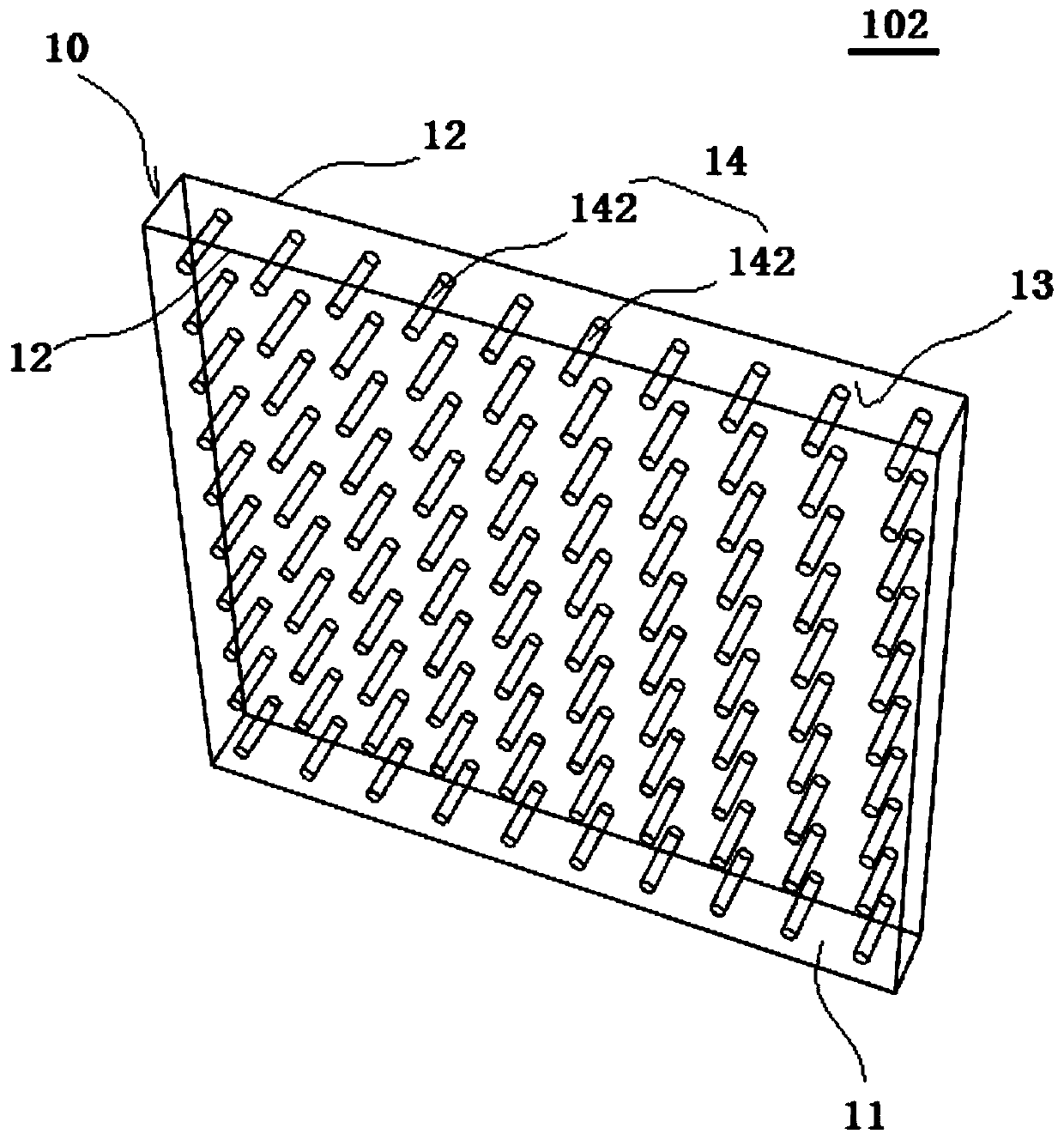

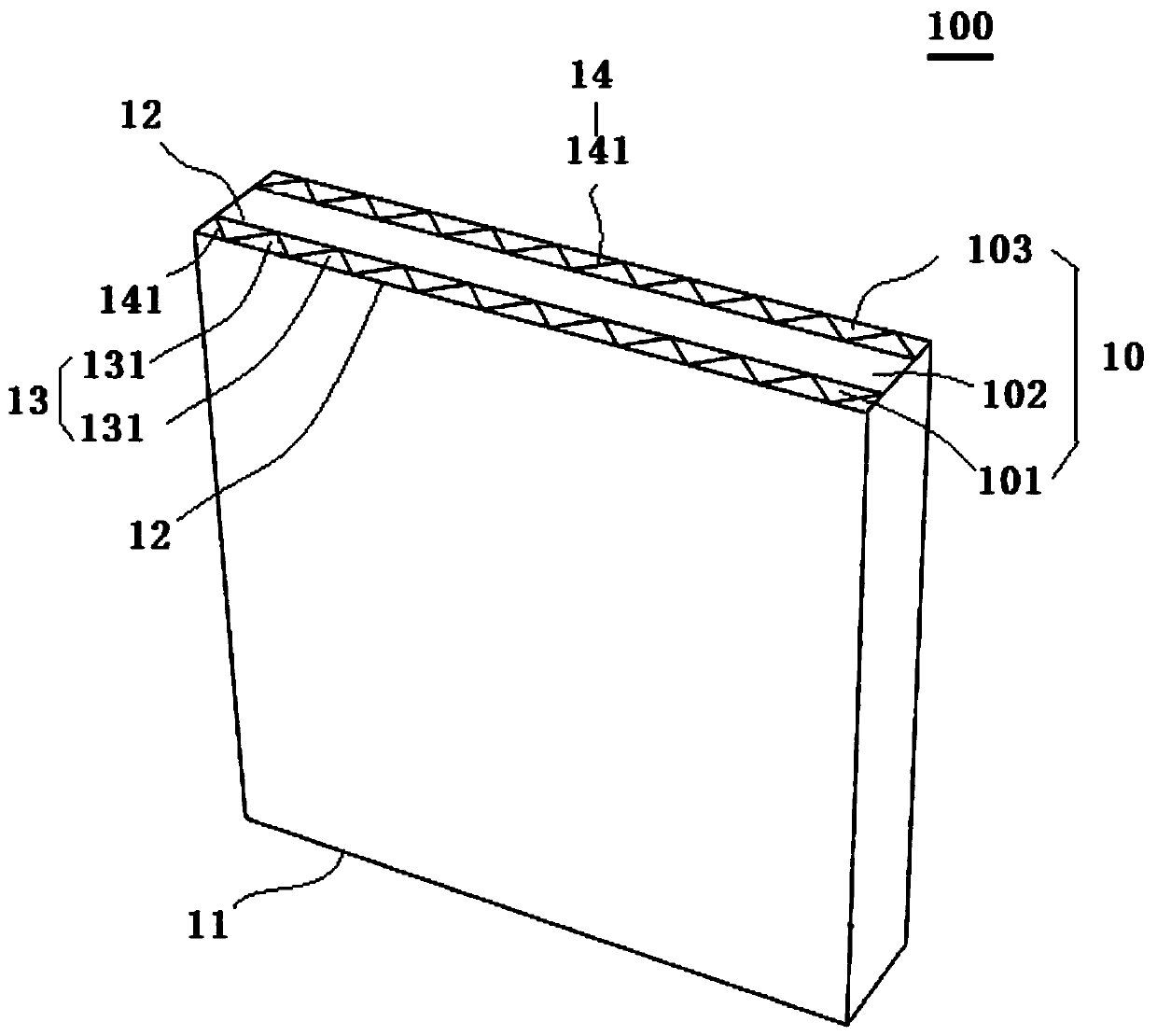

[0036] figure 1 It is a schematic perspective view of a multifunctional integrated 3D printed building enclosure according to an embodiment of the present application. figure 2 yes figure 1 The schematic perspective view of the second layer shell in the multifunctional integrated 3D printed building enclosure shown. image 3 It is a schematic perspective view of the multi-functional integrated 3D printed building enclosure according to another embodiment of the present application when filling and coating compounding are not performed. Figure 4 It is a schematic perspective view of the multi-functional integrated 3D printed building enclosure according to another embodiment of the present application when filling and coating compounding are not performed.

[0037] Such as figure 1 shown, see also Figure 2-Figure 4 , the present embodiment provides a multifunctional integrated 3D printing building enclosure, including: a multi-layer shell 10, a first filling (not shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com