A kind of ceramic-aluminum composite material for additive manufacturing, preparation method and additive manufacturing method of ceramic-aluminum composite structural parts

An aluminum composite material and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of easy oxidation, difficult forming, insufficient strength of aluminum alloy, etc., and achieve high hardness and wear resistance, good dimensional stability, and low thermal expansion The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing a ceramic-aluminum composite material for additive manufacturing according to an embodiment of the present invention includes the following steps:

[0055] S1, dispersing the aluminum alloy powder in an aqueous solution of cetyltrimethylammonium bromide, stirring, filtering, washing, and vacuum drying, to obtain positively charged aluminum alloy powder particles;

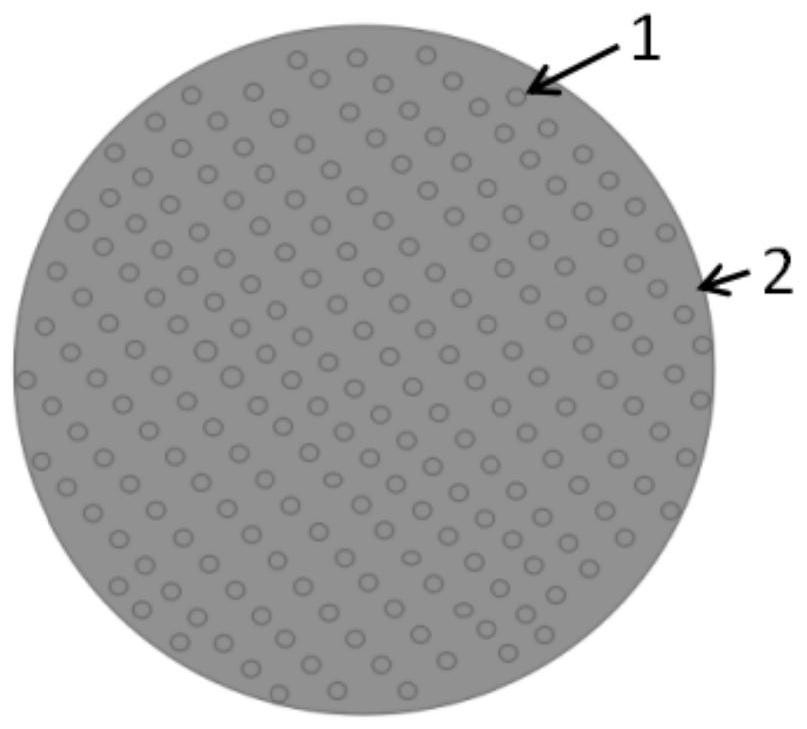

[0056] S2, disperse the nano ceramic powder and the positively charged aluminum alloy powder particles obtained in step S1 in deionized water; mix and stir to obtain negatively charged nano ceramic powder particles and make the negatively charged nano ceramic powder The particles are adsorbed on the surface of the positively charged aluminum alloy powder particles; after filtration, vacuum drying and sieving, the ceramic-aluminum composite powder for additive manufacturing is obtained;

[0057] Wherein, in step S1 and step S2, ultrasonic dispersion is used as the dispersion method; magn...

Embodiment 2

[0061] In the embodiment of the present invention, there are only the following differences from Embodiment 1, and the rest are the same, and the difference is:

[0062] In step S1, the aluminum alloy powder is Al-Cu-based and Al-Si-based mixed aluminum alloy powder; the average particle size range of the aluminum alloy powder is 50um; the cetyltrimethylammonium bromide aqueous solution The concentration range is 1mol / L.

[0063] In step S2, the mass of negatively charged nano-ceramic powder particles is 15% of the mass of positively charged aluminum alloy powder particles; the nano-ceramic powder is a mixture of silicon nitride and silicon carbide; the nano-ceramic powder The average particle size range is 300nm. A 300-mesh sieve was used for sieving.

Embodiment 3

[0065] In the embodiment of the present invention, there are only the following differences from Embodiment 1, and the rest are the same, and the difference is:

[0066] In step S1, the aluminum alloy powder is Al-Mg mixed aluminum alloy powder; the average particle size range of the aluminum alloy powder is 80um; the concentration range of the cetyltrimethylammonium bromide aqueous solution is 2mol / L.

[0067] In step S2, the mass of the negatively charged nano-ceramic powder particles is 20% of the mass of the positively charged aluminum alloy powder particles; the nano-ceramic powder is silicon carbide; the average particle diameter of the nano-ceramic powder ranges from 500nm. A 500-mesh sieve was used for sieving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com