Chip component slitting, molding detection and braiding linkage integrated machine

An all-in-one machine and component technology, which is applied in the field of chip component processing equipment, can solve the problems of low processing efficiency, high processing cost, and many manual participation parts, and achieves the effect of fast component taping, compact structure, and cost saving of taping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

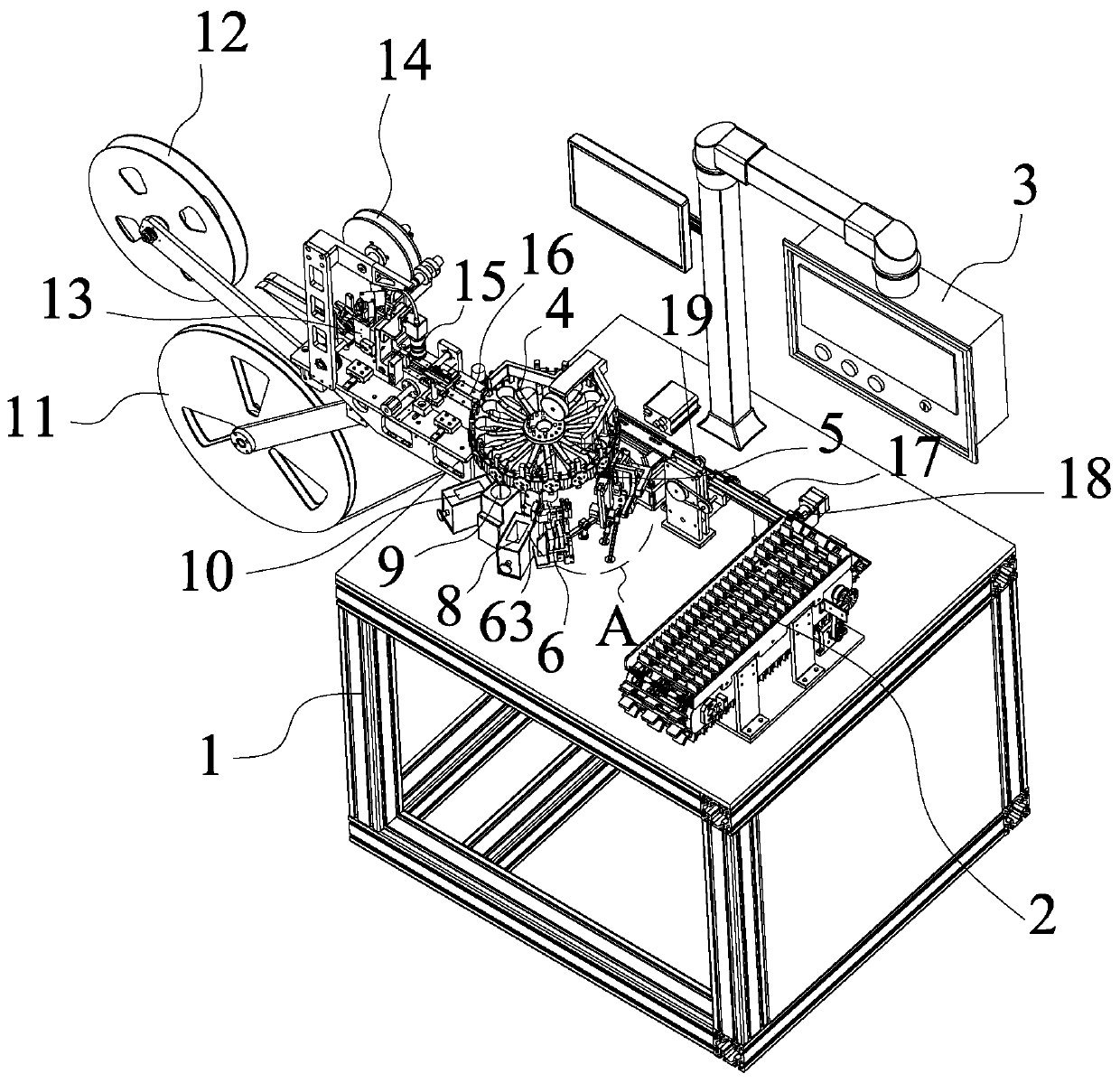

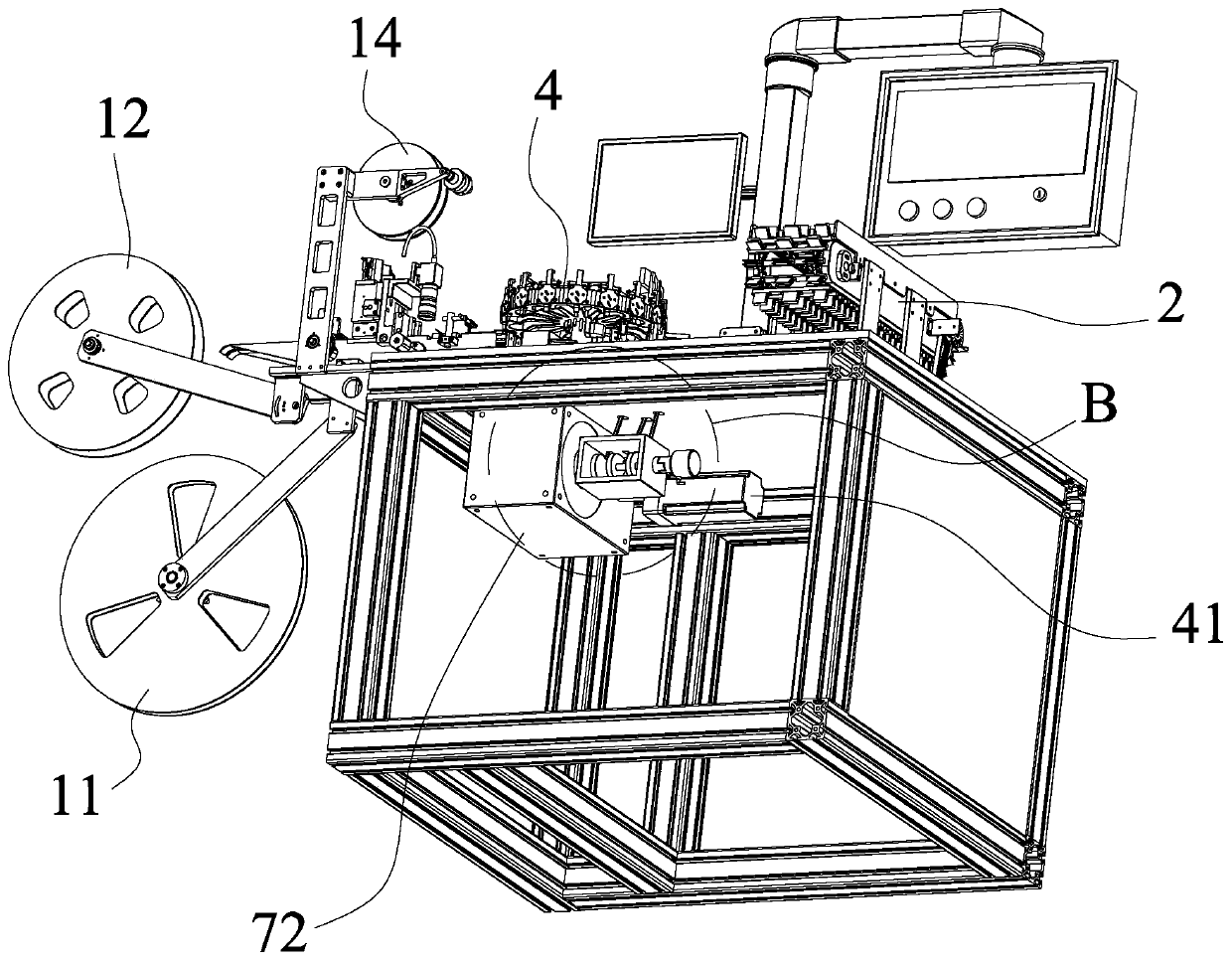

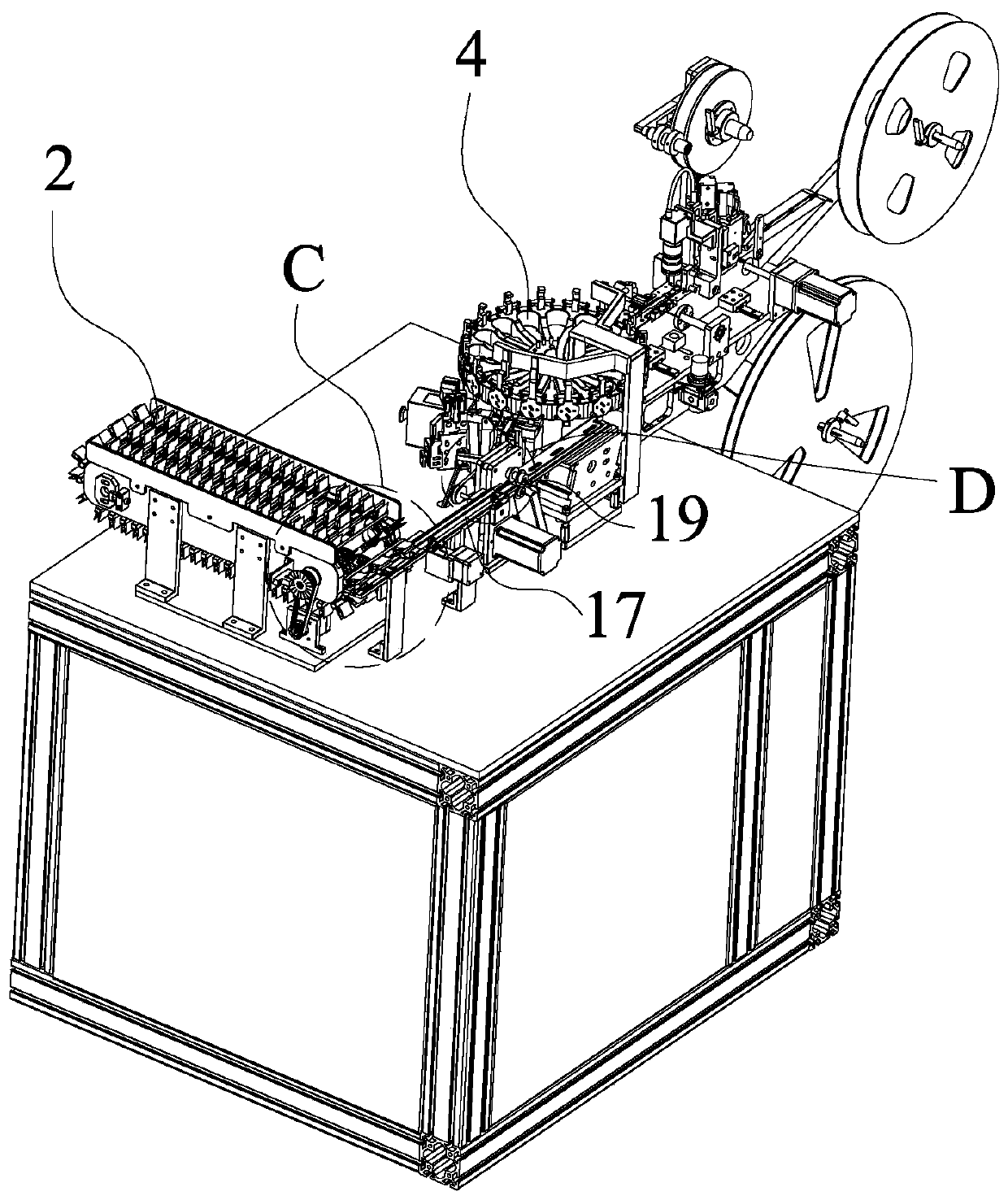

[0027] Example: such as Figure 1-7As shown, the present invention is an integrated machine for slitting, forming, detecting, and braiding of chip components, including a frame 1, a feeding mechanism 2, a control panel 3, a turntable mechanism 4, a first lead wire bending mechanism 5, and a second lead wire Bending mechanism 6, forming driving mechanism 7 and feeding channel 17, the feeding channel 17 is installed on the frame 1, and the feeding mechanism 2, pinch feeding mechanism 18, cutting mechanism 19 and turntable mechanism are arranged in sequence along the feeding channel 17 4. The periphery of the turntable mechanism 4 is sequentially provided with a first lead wire bending mechanism 5, a second lead wire bending mechanism 6, an electric measuring mechanism 63, a first defective product discharge groove 8, a CCD shape detection mechanism 9, and a second non-conductive wire bending mechanism. A good product discharge trough 10 and a blanking and braiding mechanism, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com