A processing device and processing method for a combined pipeline

A processing method and pipeline technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of difficulty in guaranteeing welding quality, and achieve the effect of realizing welding work, improving efficiency and precision, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

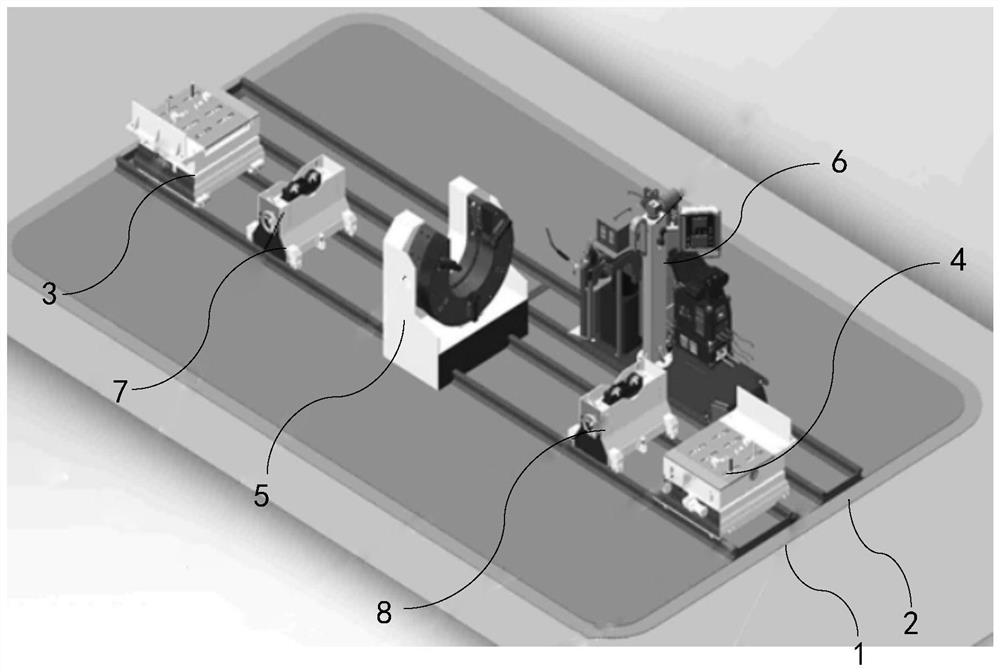

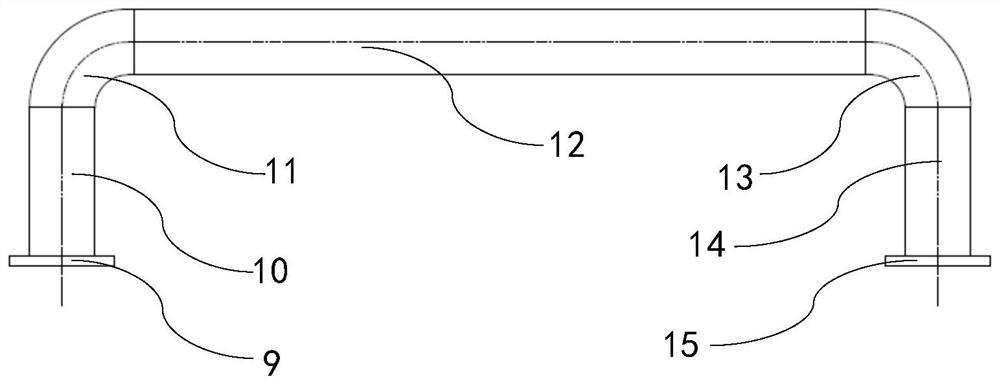

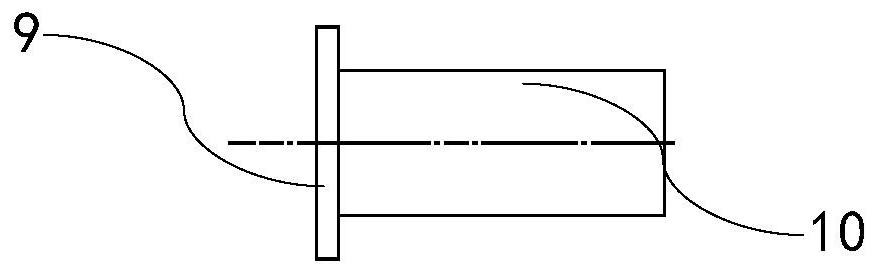

[0034] See attached Figure 1-2 , the present invention also provides a processing method for combined pipes, which includes the processing device described above, sequentially combined and connected the first flange 9, the first straight pipe 10, the first elbow 11 and the second straight pipe 12, Described method comprises the following steps: 1) refer to appendix image 3 , first perform circular seam welding on the first flange 9 and the first straight pipe 10, fix the first straight pipe 10 on the open pipe wrench, and place the first flange 9 fixed on the first pair of machines 3 or the second pair of machines 4, adjust the first group of machines 3 or the second set of machines 4 so that the first flange 9 and the first straight pipe 10 Centering, the first flange 9 and the first straight pipe 10 are spot welded and fixed by the welding special machine system 6; the pairing machine on which the first flange 9 is fixed is pushed away to start The open-type pipe wrench ...

Embodiment 2

[0037] Further, see the attached Figure 5 , when it is necessary to combine the elbow, straight pipe and elbow in sequence, according to the length of the straight pipe, adjust the position between the first bracket 7 and the second bracket 8 to support the straight pipe; fix the straight pipe For the open-type pipe wrench, adjust the height of the first bracket 7 and the second bracket 8 so that it can support straight pipes, and at the same time adjust the first set of pairing machines 3 and the second set of pairing machines. The position of the welding machine 4, place the elbow to be installed on the assembly position on the platform of the pairing machine, and then adjust the height of the platform of the matching machine so that the position of the elbow is aligned with the straight pipe, and push the special welding machine system 6 to a suitable welding position. spot-weld the elbow and the straight pipe so that the two ends of the elbow and the straight pipe are spo...

Embodiment 3

[0039] See attached Image 6 , when it is necessary to process the combined pipe of flange, straight pipe and elbow in sequence, according to the length of the straight pipe, adjust the position between the first bracket 7 and the second bracket 8 to support the straight pipe; Fix it on the open pipe wrench, adjust the height of the first bracket 7 and the second bracket 8 so that it can support straight pipes, and adjust the first group of pairing machines 3 and the second group For the position of the machine 4, place the elbow to be installed on the assembly position of one of the assembly machines, then adjust the height of the assembly machine so that the elbow and the straight pipe are aligned, and push the welding special machine system 6 to a suitable welding position. For the spot welding of the elbow and the straight pipe, hoist the flange to be installed and place it on the hanging plate of another assembly machine, then adjust the position to align with the straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com