A heterojunction core-shell lafeo 3 @g-c 3 no 4 Nanocomposite materials and their preparation methods and applications

A nanocomposite material and technology of composite materials are applied in the field of preparation of heterojunction core-shell LaFeO3@g-C3N4 nanocomposite materials, which can solve problems such as absorption limitation in the visible light region, and achieve enhanced interfacial interaction and photoelectric stability. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

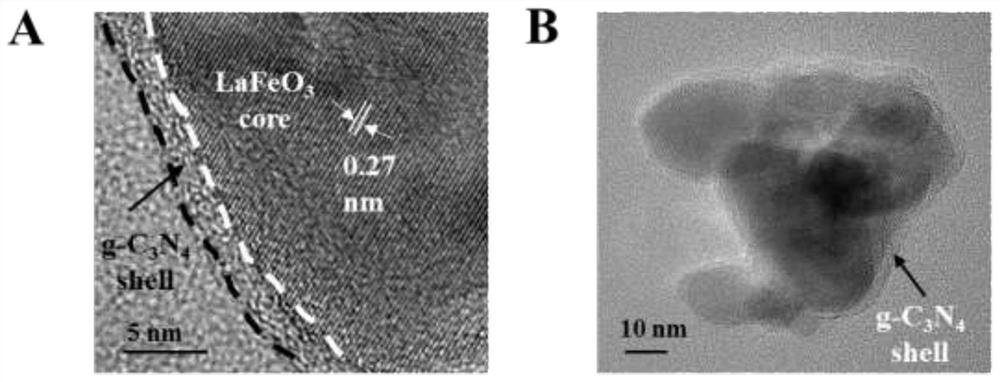

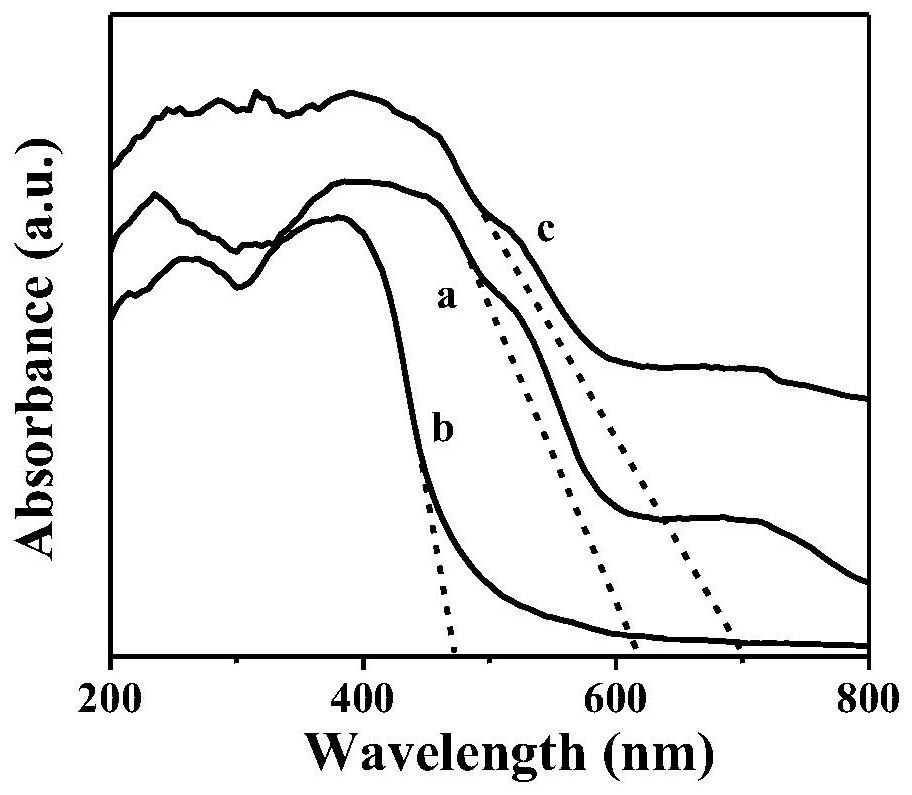

[0034] Heterojunction core-shell LaFeO 3 @g-C 3 N 4 one-step preparation of

[0035] (1) g-C 3 N 4 preparation of

[0036] Weigh 10g of melamine, put it into four crucibles, put it into a tube furnace, and calcinate at 550°C for 4 hours, with a heating rate of 2°C / min. The prepared solids were ground into powders and subjected to secondary calcination at the same temperature. Then, weigh g-C 3 N 4 4.856g of powder was dispersed in 20mL of ultrapure water, and ultrasonically treated for 6 hours to obtain g-C 3 N 4 The suspension was used further.

[0037] (2) Heterojunction core-shell LaFeO 3 @g-C 3 N 4 One-step preparation of composite materials

[0038] Dissolve 10 mmol of citric acid, 5 mmol of lanthanum nitrate hexahydrate, and 5 mmol of ferric nitrate nonahydrate in 30 mL of a mixed solvent of ultrapure water and ethanol, wherein the ratio of ultrapure water to ethanol is 1:2. Subsequently, the mixture was stirred at room temperature for 30 minutes. After h...

Embodiment 2

[0050] Heterojunction core-shell LaFeO 3 @g-C 3 N 4 one-step preparation of

[0051] (1) g-C 3 N 4 preparation of

[0052] Weigh 10g of melamine, put it into four crucibles, put it into a tube furnace, and calcinate at 550°C for 4 hours, with a heating rate of 2°C / min. The prepared solids were ground into powders and subjected to secondary calcination at the same temperature. Then, weigh g-C3 N 4 1.5g of the powder was dispersed in 33mL of ultrapure water, and ultrasonically treated for 3 hours to obtain g-C 3 N 4 The suspension was used further.

[0053] (2) Heterojunction core-shell LaFeO 3 @g-C 3 N 4 One-step preparation of composite materials

[0054] Dissolve 8 mmol of citric acid, 4 mmol of lanthanum nitrate hexahydrate, and 4 mmol of ferric nitrate nonahydrate in 20 mL of a mixed solvent of ultrapure water and ethanol, wherein the ratio of ultrapure water to ethanol is 1:2. Subsequently, the mixture was stirred at room temperature for 20 minutes. After he...

Embodiment 3

[0056] Heterojunction core-shell LaFeO 3 @g-C 3 N 4 one-step preparation of

[0057] (1) g-C 3 N 4 preparation of

[0058] Weigh 10g of melamine, put it into four crucibles, put it into a tube furnace, and calcinate at 550°C for 4 hours, with a heating rate of 2°C / min. The prepared solids were ground into powders and subjected to secondary calcination at the same temperature. Then, weigh g-C 3 N 4 13g of powder was dispersed in 26mL of ultrapure water, and ultrasonically treated for 9 hours to obtain g-C 3 N 4 The suspension was used further.

[0059] (2) Heterojunction core-shell LaFeO 3 @g-C 3 N 4 One-step preparation of composite materials

[0060] Dissolve 12 mmol of citric acid, 6 mmol of lanthanum nitrate hexahydrate, and 6 mmol of ferric nitrate nonahydrate in 40 mL of a mixed solvent of ultrapure water and ethanol, wherein the ratio of ultrapure water to ethanol is 1:2. Subsequently, the mixture was stirred at room temperature for 40 minutes. After heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com