Straw picking and crushing baler and baling mechanism thereof

A technology for picking up crushing and bundling mechanisms, which is applied to agricultural machinery and tools, packers, loaders, etc. It can solve the problems of low production efficiency, manual bagging and packing, etc., achieve production and processing safety, reduce labor costs, and improve packing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

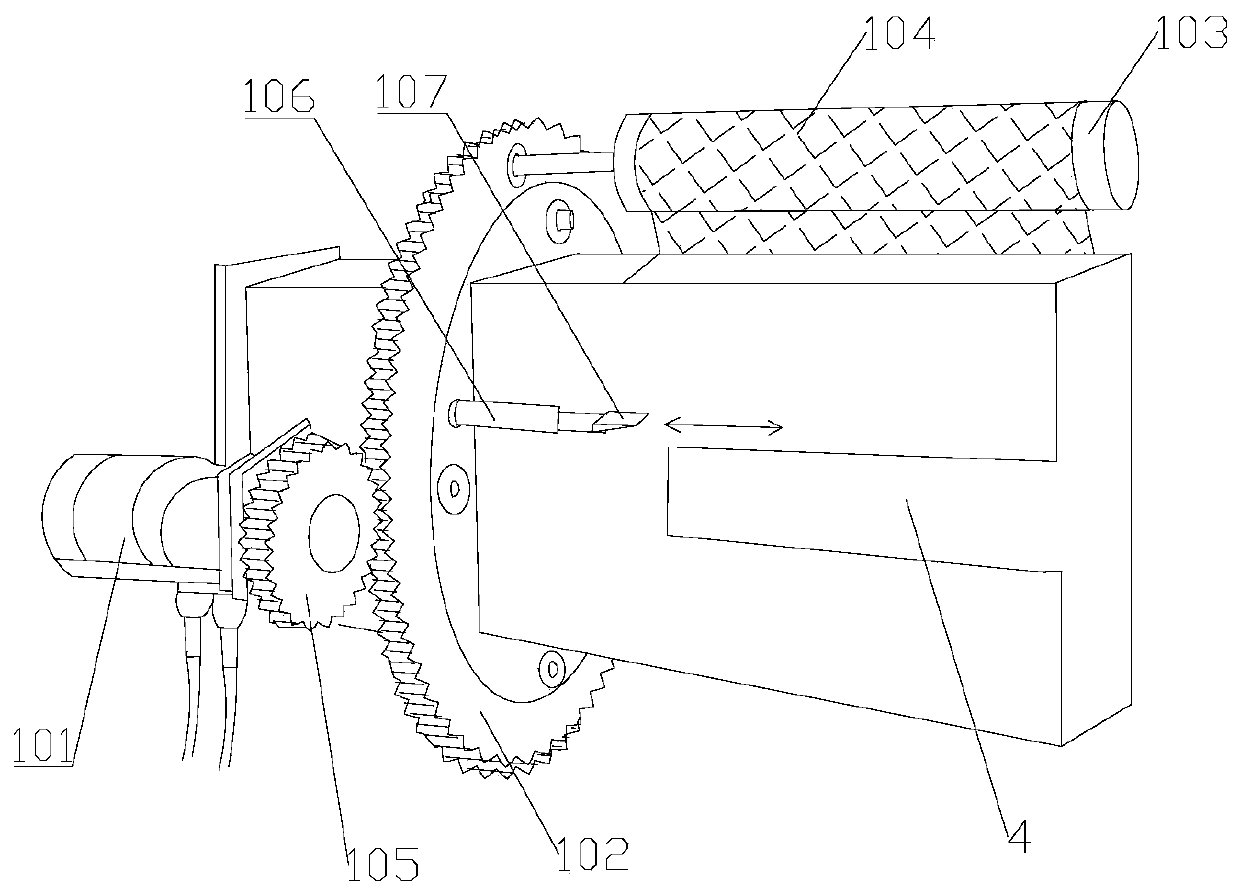

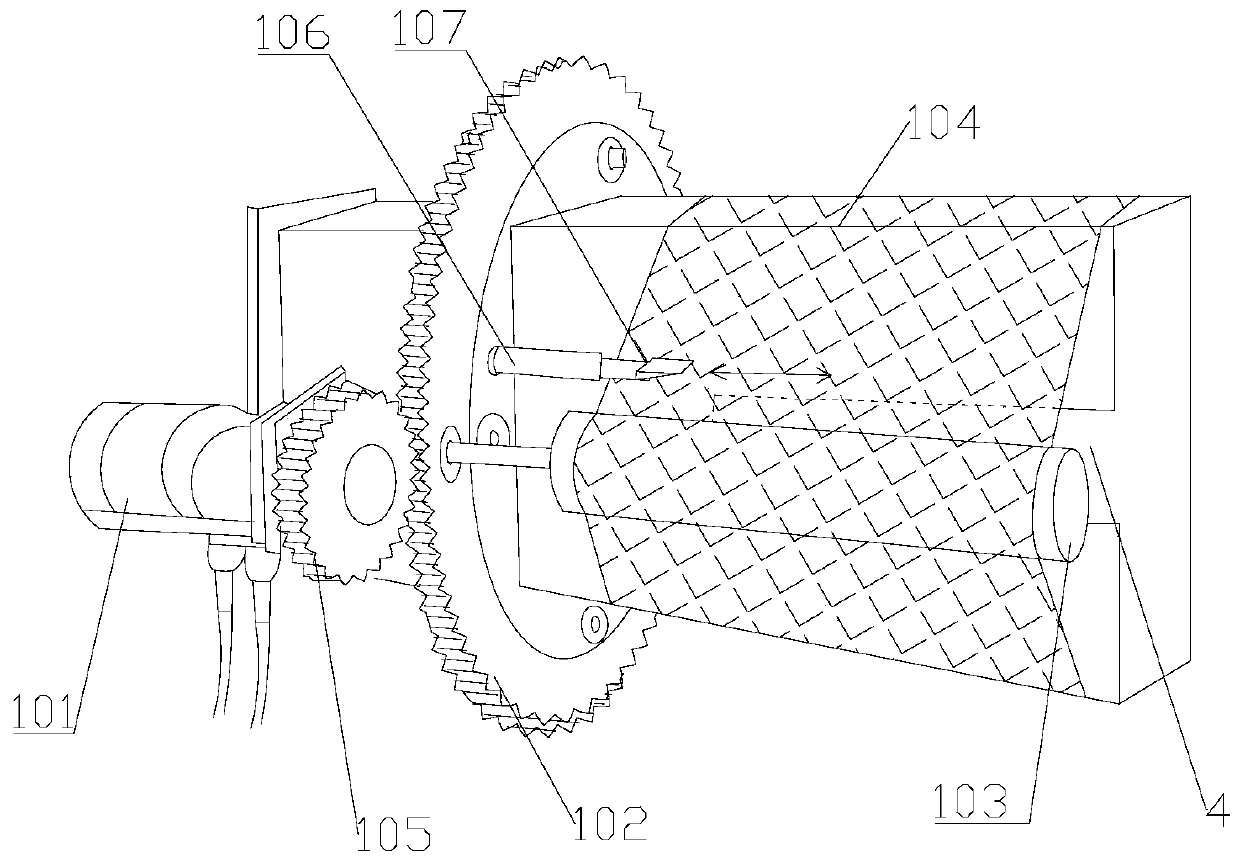

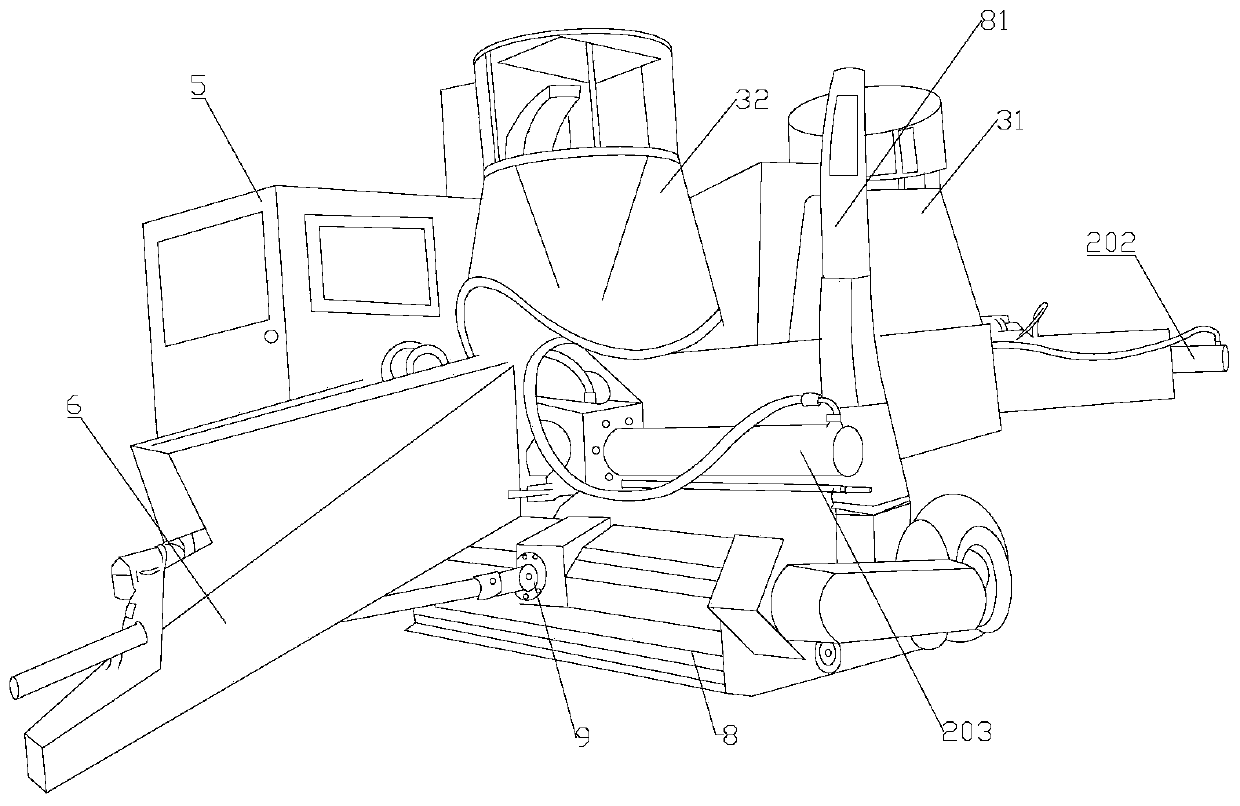

[0044] Such as figure 1 and figure 2 As shown, the above-mentioned bundling mechanism includes a hydraulic motor 101, a rotating wheel 102 and a packing roller 103, wherein: the rotating wheel 102 is fixed on the periphery of the discharge port 4 of the feed bin of the bundling machine, and the hydraulic motor 101 can drive the rotating wheel 102 rotates in its plane with the discharge port 4 as the axis; wherein, the above-mentioned plane refers to the plane where the rotating wheel 102 is located, that is, the plane perpendicular to the extending direction of the discharging port 4; the rotating wheel 102 can use For the ring structure, in order to realize that it can rotate around the periphery of the discharge port 4, the rotating wheel 102 can be fixed on the periphery of the discharge port 4 through structures such as bearings.

[0045]Packing roller 103 is fixed on the rotating wheel 102 and is arranged towards the discharge port 4 side, it can be fixed on the side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com