An anti-broken bar motor rotor

A motor rotor and anti-break technology, applied in asynchronous induction motors, electromechanical devices, electrical components, etc., can solve the problems of broken bars, too long bars sticking out of the iron core, broken bars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

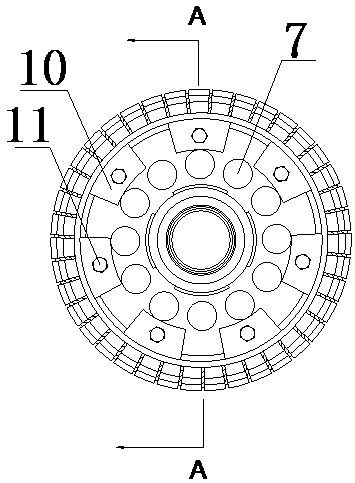

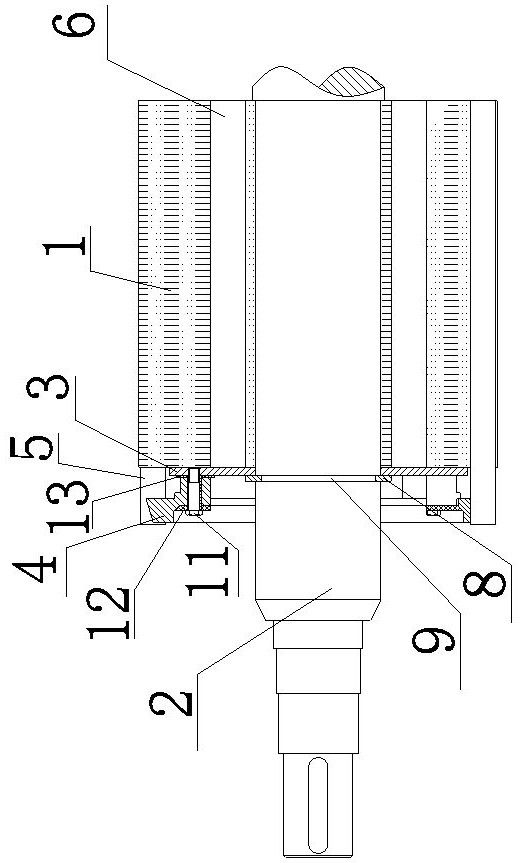

[0023] The anti-break bar motor rotor of the present embodiment, as figure 1 and figure 2 , comprising: comprising: a silicon steel sheet iron core 1, a rotor shaft 2 passing through the center hole of the silicon steel sheet iron core 1, a pressing plate 3 pressed on both ends of the silicon steel sheet iron core 1 and a short-circuit ring 4 positioned outside the pressing plate 3. Since the two ends of the silicon steel sheet iron core 1 have the same structure, only one end is used for illustration in the figure.

[0024] The silicon steel sheet iron core 1 has a semi-open core slot, and guide bars 5 are embedded in the iron core slot. There are 12 axial ventilation holes 6 in the silicon steel sheet iron core 1, and the pressure plate 3 has one-to-one correspondence with the ventilation holes 6. Hole 7. In this way, heat dissipation channels can be effectively increased to improve heat dissipation.

[0025] The pressure plate 3 is fixedly connected with three stoppers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com