Packaging structure for display

A packaging structure and display technology, applied in applications, electronic equipment, household appliances, etc., can solve the problems of complex film-forming equipment, unfavorable film properties, degradation or yellowing, etc., achieve low light transmittance and reflectance, and improve quality and stability, good shading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as "upper", "lower", "front", "rear", "left", "right", etc., are only referring to the directions of the drawings. Accordingly, the directional terms used are illustrative, not limiting, of the invention. Also, in the following embodiments, the same or similar components will be given the same or similar symbols.

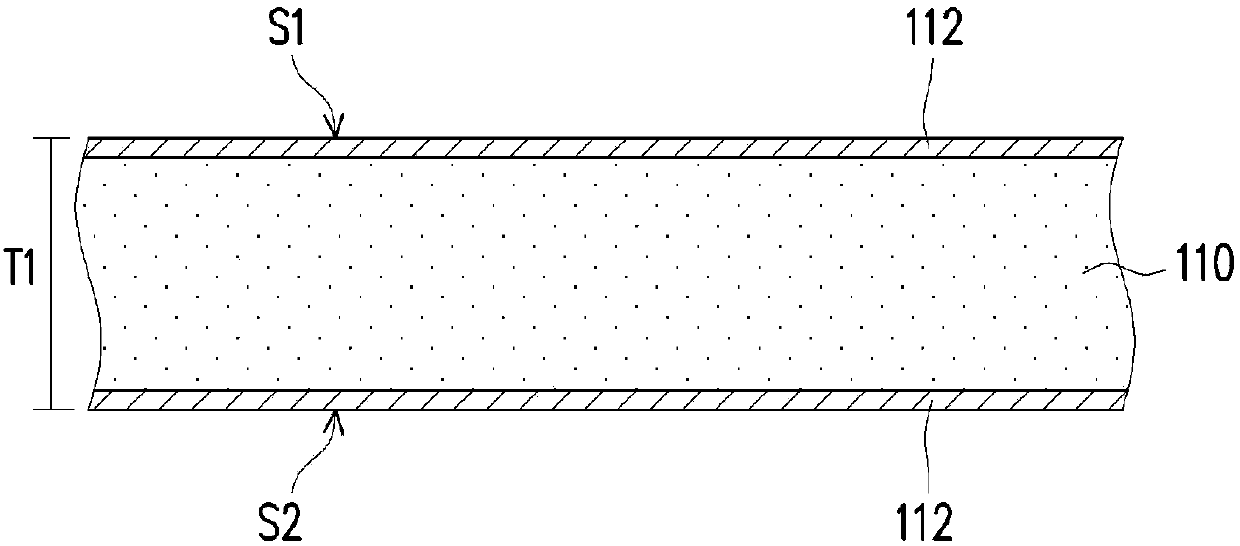

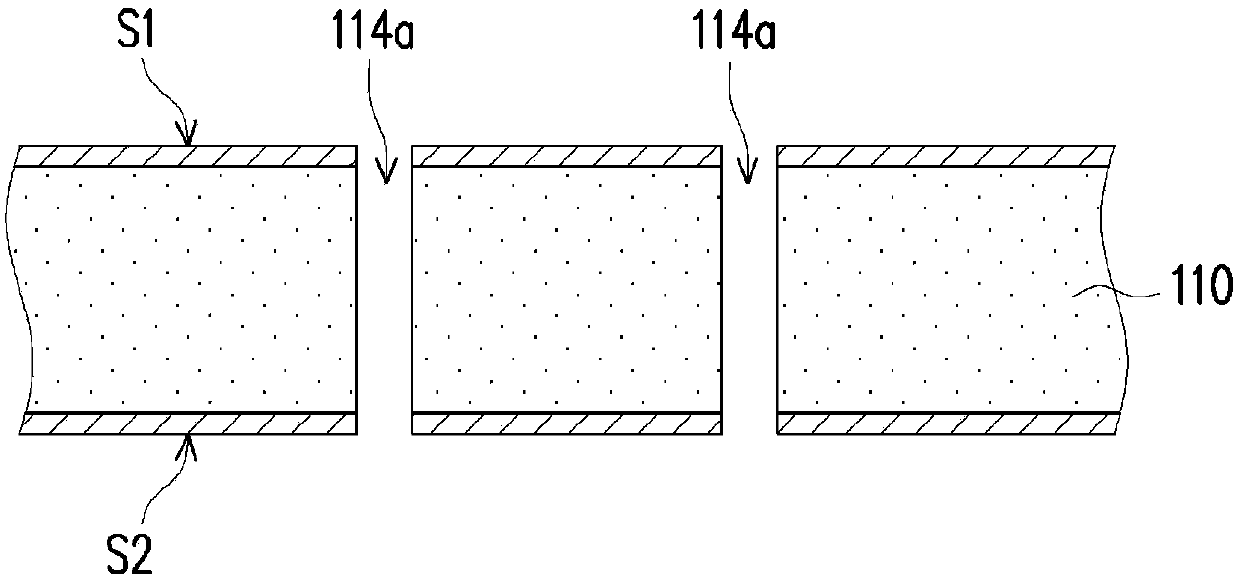

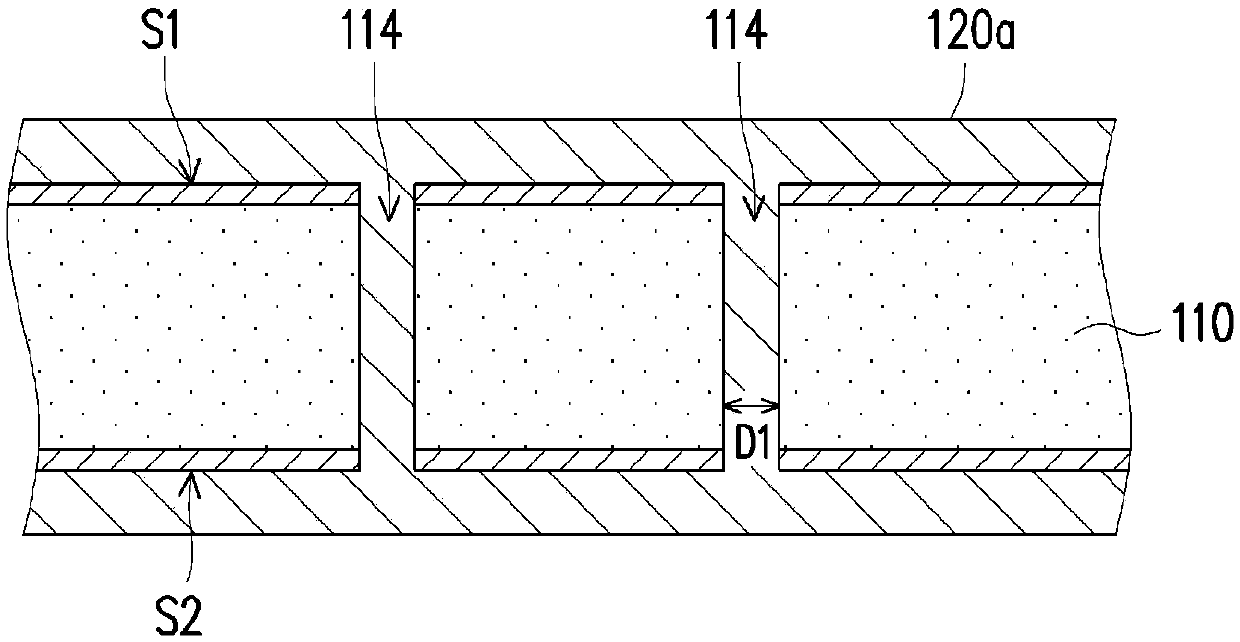

[0047] Figure 1 to Figure 5 It is a schematic cross-sectional view of a manufacturing process of a packaging structure for a display according to an embodiment of the present invention. The packaging structure 100 of this embodiment is suitable for displays, such as polymer organic light-emitting diode (PolymerLight-Emitting Diode, PLED) display, organic light-emitting dio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com