Converter alloy information tracing method and device

An alloy and converter technology, applied in the field of converter alloy information traceability, can solve the problems of time-consuming and wasteful, unable to query and track in real time, prone to human errors, etc., to improve the level of quality control, improve the level of quality control and traceability , The effect of improving the efficiency of alloy use management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

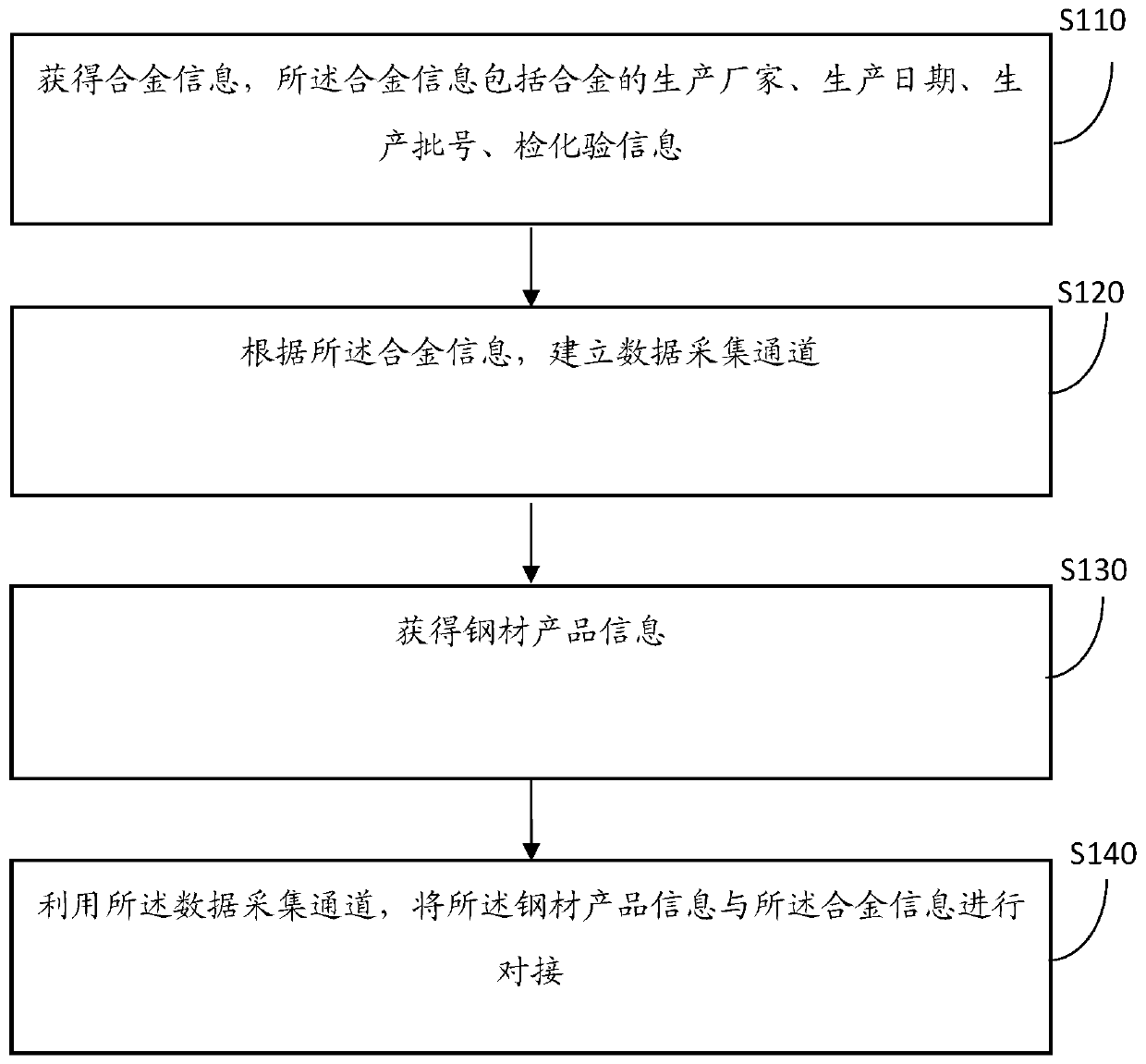

[0047] figure 1 It is a schematic flowchart of a converter alloy information tracing method in an embodiment of the present invention. like figure 1 As shown, the embodiment of the present invention provides a method for tracing converter alloy information, the method comprising:

[0048]Step 110: Obtain alloy information, which includes alloy manufacturer, production date, production batch number, and inspection and testing information.

[0049] Specifically, in the process of traceability of converter alloy information, it is necessary to know the content of alloy information, such as the manufacturer of the alloy, production date, production batch, inspection and testing information, etc. Alloy is the key raw material for steelmaking production, and the Product quality has an important impact. Different manufacturers and batches of alloys have quality differences, and the quality of steel products produced will also vary. Controlling the information of alloy principles is...

Embodiment 2

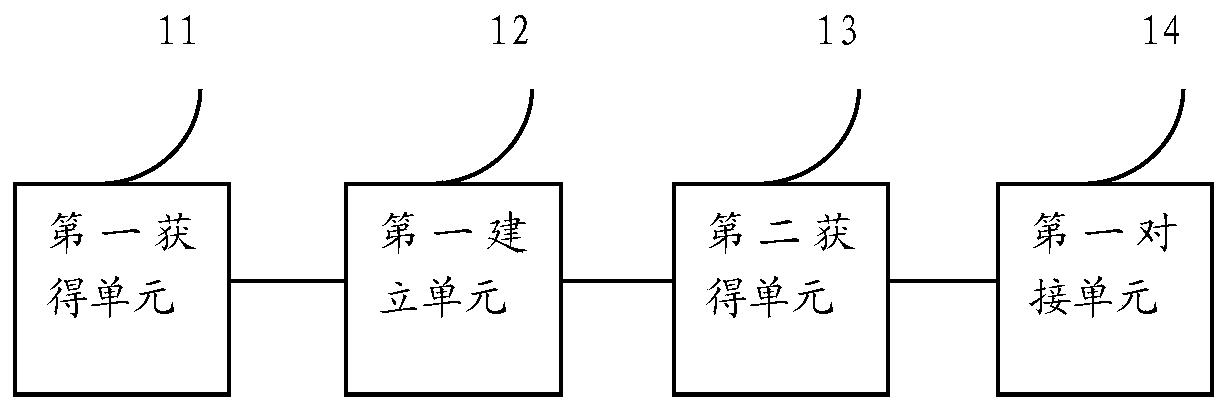

[0062] Based on the same inventive concept as a converter alloy information tracing method in the foregoing embodiments, the present invention also provides a converter alloy information tracing device, such as figure 2 As shown, the device includes:

[0063] The first obtaining unit 11, the first obtaining unit 11 is used to obtain alloy information, the alloy information includes the manufacturer of the alloy, production date, production batch number, inspection and testing information;

[0064] A first establishment unit 12, the first establishment unit 12 is used to establish a data collection channel according to the alloy information;

[0065] A second obtaining unit 13, the second obtaining unit 13 is used to obtain steel product information;

[0066] The first docking unit 14 is configured to use the data collection channel to connect the steel product information with the alloy information.

[0067] Further, the device also includes:

[0068] A third obtaining uni...

Embodiment 3

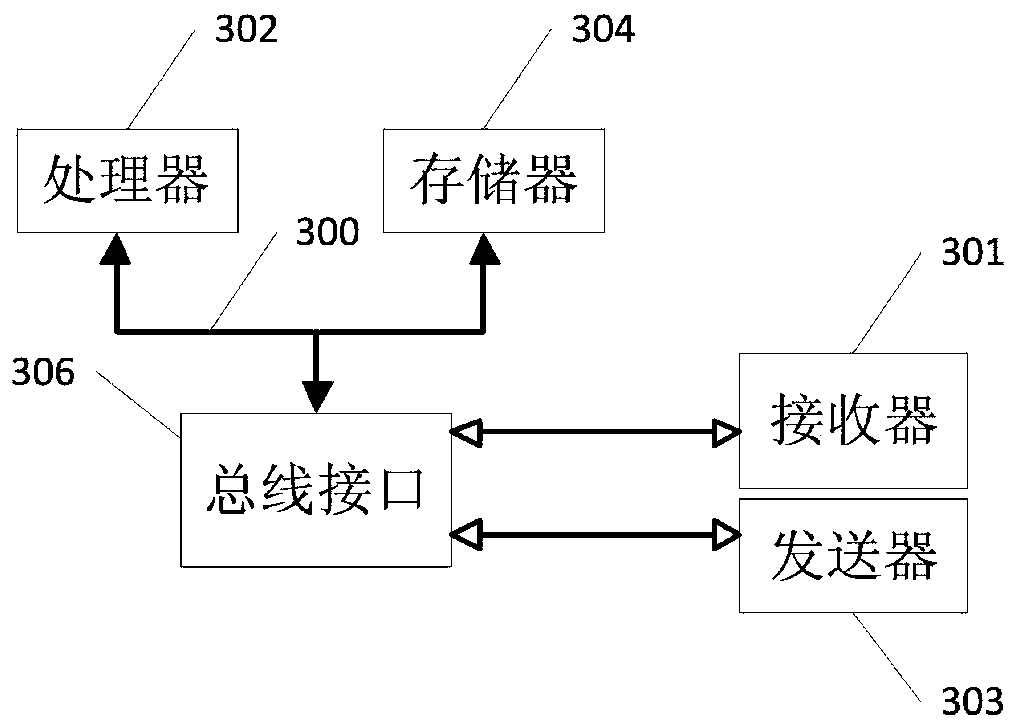

[0083] Based on the same inventive concept as the converter alloy information tracing method in the foregoing embodiments, the present invention also provides a converter alloy information tracing device, on which a computer program is stored, and when the program is executed by a processor, the aforementioned one Steps in either method of the BOF alloy information traceability method.

[0084] Among them, in image 3 In, bus architecture (represented by bus 300), bus 300 may include any number of interconnected buses and bridges, bus 300 will include one or more processors represented by processor 302 and various types of memory represented by memory 304 circuits linked together. The bus 300 may also link together various other circuits, such as peripherals, voltage regulators, and power management circuits, etc., which are well known in the art and thus will not be further described herein. The bus interface 306 provides an interface between the bus 300 and the receiver 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com