Automatic efficient textile product drying device

A drying device and textile technology, which is applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of inadequate drying treatment, reduced drying efficiency, time-consuming and labor-intensive, etc., and achieve the effect of improving the pulling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

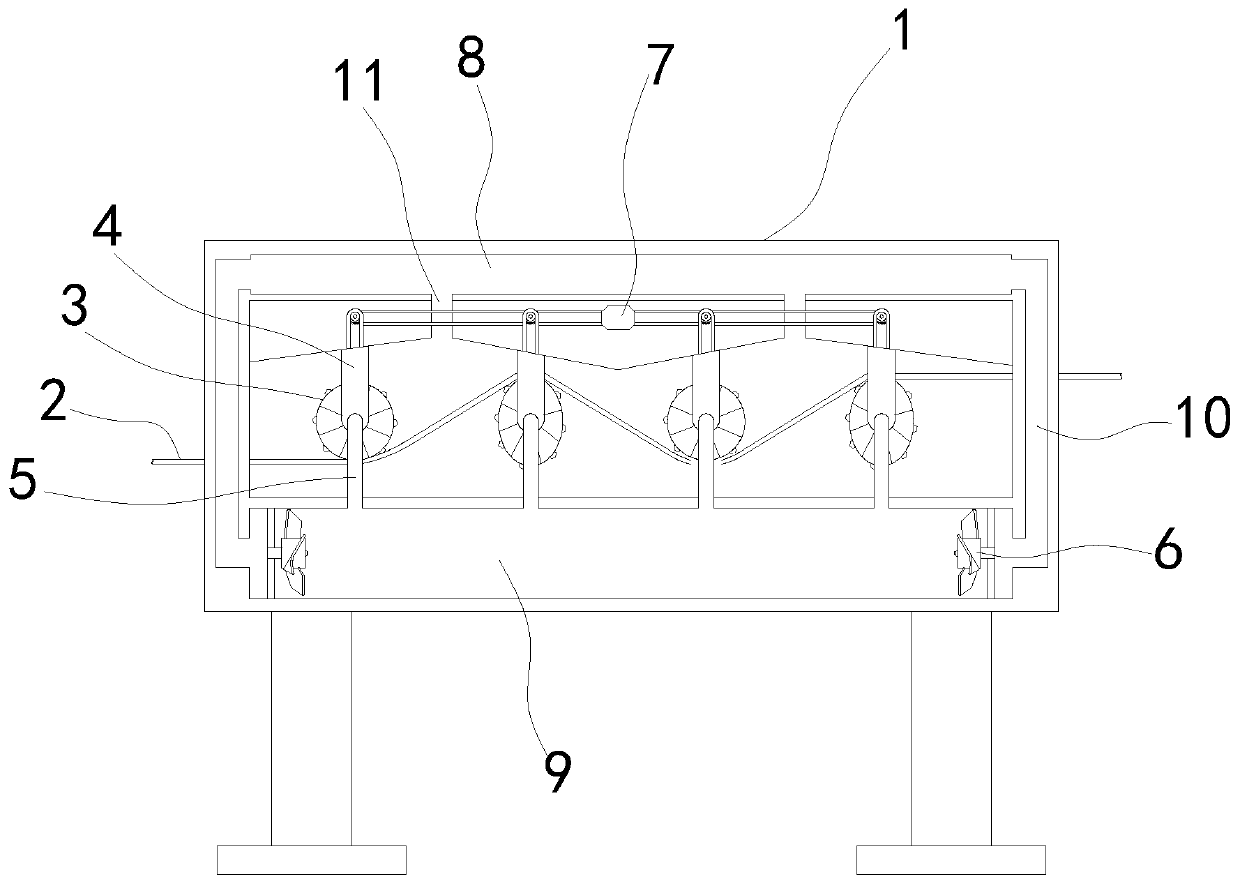

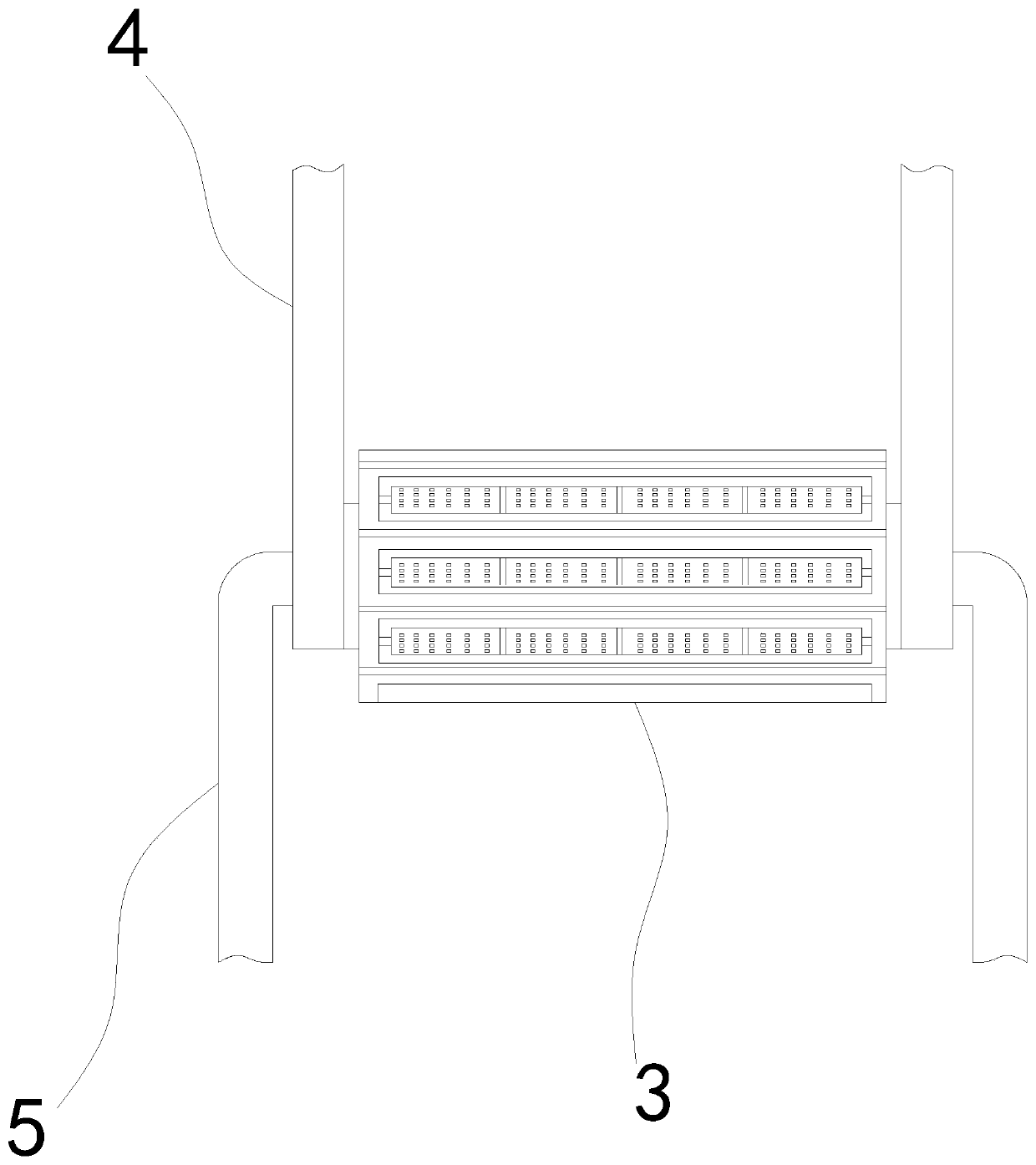

[0029] see Figures 1 to 9 , a schematic diagram of the planar structure and a schematic diagram of the three-dimensional structure of an automatic high-efficiency textile drying device.

[0030] An automatic high-efficiency drying device for textiles, comprising a device main body 1 and a textile cloth 2, the upper end of the device main body 1 is provided with a condensation chamber 8, the lower end of the condensation chamber 8 is fixedly connected with a steam inlet channel 11, and the lower end of the condensation chamber 8 is fixedly installed with a motor 7 , the two ends of the condensation chamber 8 are fixedly connected with a ventilation pipe 10, the lower end of the ventilation pipe 10 is fixedly connected with an air inlet chamber 9, the fan 6 is fixedly installed in the air inlet chamber 9, and the upper end of the air inlet chamber 9 is fixedly connected with an air inlet pipe 5, the main body of the device 1 A drying device 3 is fixedly installed inside, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com