Discharging device of digester for preventing blockage of lifting conveying pipe

A technology of a digester and a conveying pipe is applied in the field of a digester unloading device, which can solve the problems of reducing the feeding efficiency and easy blockage of a hopper elevator, and achieve the effects of improving the feeding efficiency, improving the pulling efficiency and reducing the difficulty of pulling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

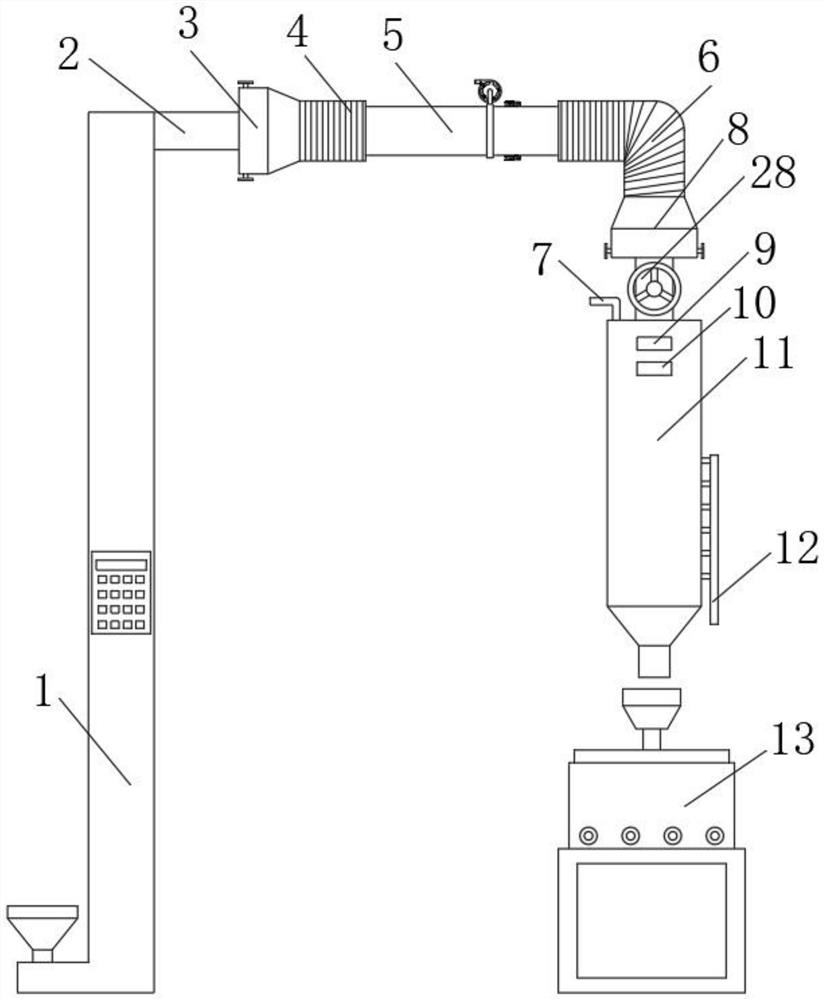

[0030] Embodiment 1: A digester unloading device for preventing clogging of the lifting conveying pipe, comprising a feeding pipe 5, a cooking assembly is installed at the discharge end of the feeding pipe 5, and a feeding assembly is installed at the feeding end of the feeding pipe 5 , a second connecting assembly is installed between the cooking assembly and the feeding pipe 5, a first connecting assembly is installed between the feeding assembly and the feeding pipe 5, a tablet press 13 is installed at the discharge end of the cooking assembly, and the feeding pipe 5 A one-way feed assembly is installed inside the one-way feed assembly. The one-way feed assembly allows the material to flow only from the first connection assembly to the second connection assembly. The feed assembly includes a hopper elevator 1, and the discharge end of the hopper elevator 1 is installed with a Feed pipe 2, the cooking assembly includes a cooking tank 11, a high-level material machine 9 and a ...

Embodiment 2

[0032] Embodiment 2: A digester feeding device for preventing clogging of the lifting conveying pipe, comprising a feeding pipe 5, a cooking assembly is installed at the discharge end of the feeding pipe 5, and a feeding assembly is installed at the feeding end of the feeding pipe 5 , a second connecting assembly is installed between the cooking assembly and the feeding pipe 5, a first connecting assembly is installed between the feeding assembly and the feeding pipe 5, a tablet press 13 is installed at the discharge end of the cooking assembly, and the feeding pipe 5 A one-way feed assembly is installed inside the one-way feed assembly. The one-way feed assembly allows the material to flow only from the first connection assembly to the second connection assembly. The feed assembly includes a hopper elevator 1, and the discharge end of the hopper elevator 1 is installed with a Feed pipe 2, the cooking assembly includes a cooking tank 11, a high-level material machine 9 and a bo...

Embodiment 3

[0034] Embodiment 3: A digester feeding device for preventing clogging of the lifting conveying pipe, comprising a feeding pipe 5, a cooking assembly is installed at the discharge end of the feeding pipe 5, and a feeding assembly is installed at the feeding end of the feeding pipe 5 , a second connecting assembly is installed between the cooking assembly and the feeding pipe 5, a first connecting assembly is installed between the feeding assembly and the feeding pipe 5, a tablet press 13 is installed at the discharge end of the cooking assembly, and the feeding pipe 5 A one-way feed assembly is installed inside the one-way feed assembly. The one-way feed assembly allows the material to flow only from the first connection assembly to the second connection assembly. The feed assembly includes a hopper elevator 1, and the discharge end of the hopper elevator 1 is installed with a Feed pipe 2, the cooking assembly includes a cooking tank 11, a high-level material machine 9 and a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com