Recyclable temporary bracket for installing steel sheet pile cofferdam purlin

A steel sheet pile cofferdam, temporary technology, applied in construction, infrastructure engineering and other directions, can solve the problems of inconvenient operation, large material loss, low construction efficiency, etc., to achieve convenient and quick installation and disassembly, improve construction efficiency, reduce construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

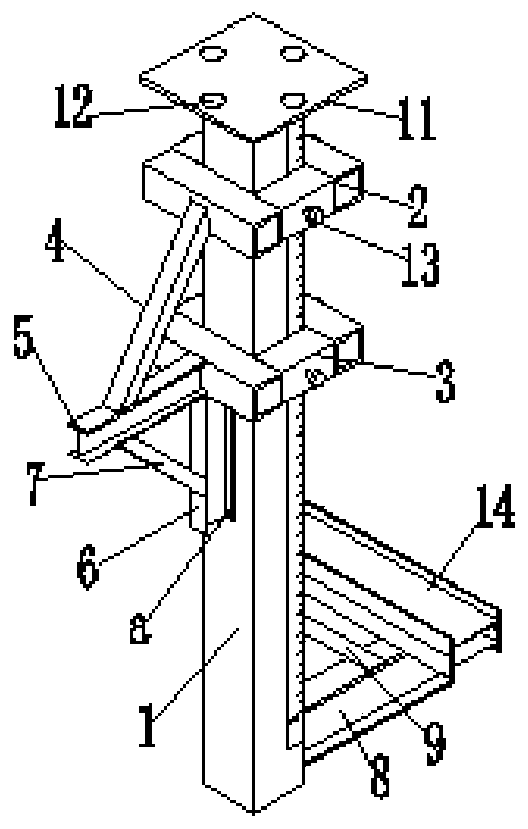

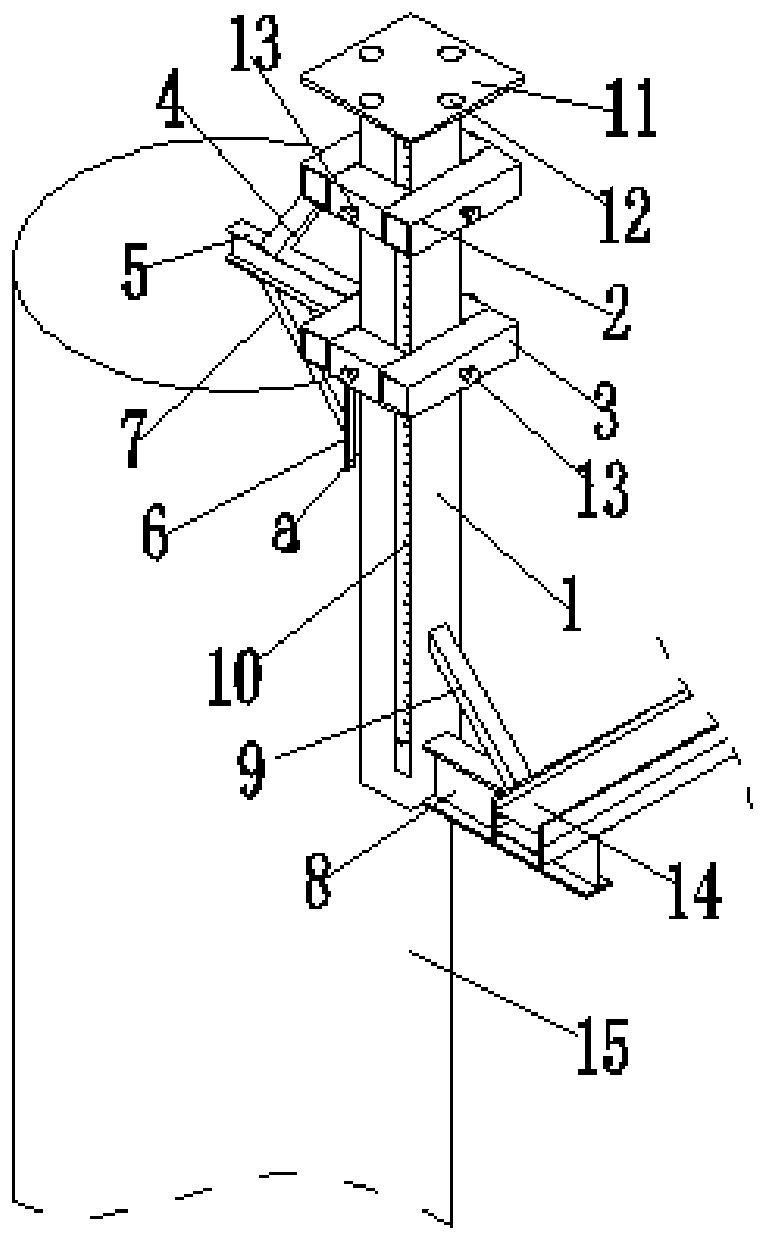

[0016] Embodiments of the present invention refer to figure 1 and figure 2 , a recyclable temporary corbel for the installation of steel sheet pile cofferdam purlins; a scale 10 is installed on the side of the column 1, so that the zero scale line of the scale 10 is flush with the upper edge of the second cross bar 8 ; The upper ring 2 and the lower ring 3 are respectively set on the upper end of the column 1, the first cross bar 5 is welded on the side wall of the lower ring 3, and the two ends of the first diagonal bar 4 are respectively welded to the first cross bar 5 On the top surface of the left end of the top and the side of the upper ring 2, a triangular bracket structure is formed between the first cross bar 5, the first oblique bar 4, the upper ring 2 and the lower ring 3;

[0017] In this embodiment, one end of the stopper 6 is welded on the lower bottom surface of the first crossbar 5, and the distance between the stopper 6 welded on the lower bottom surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com