Structural and functional integrated tempered vacuum glass and manufacturing method thereof

A technology of vacuum glass and manufacturing method, which is applied in the field of building materials production, can solve the problems of low safety performance of vacuum glass, loss of tempering performance, and reduced performance of tempered glass, etc., and achieves excellent safety and reliability, broad application market, and enhancement of peripheral strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

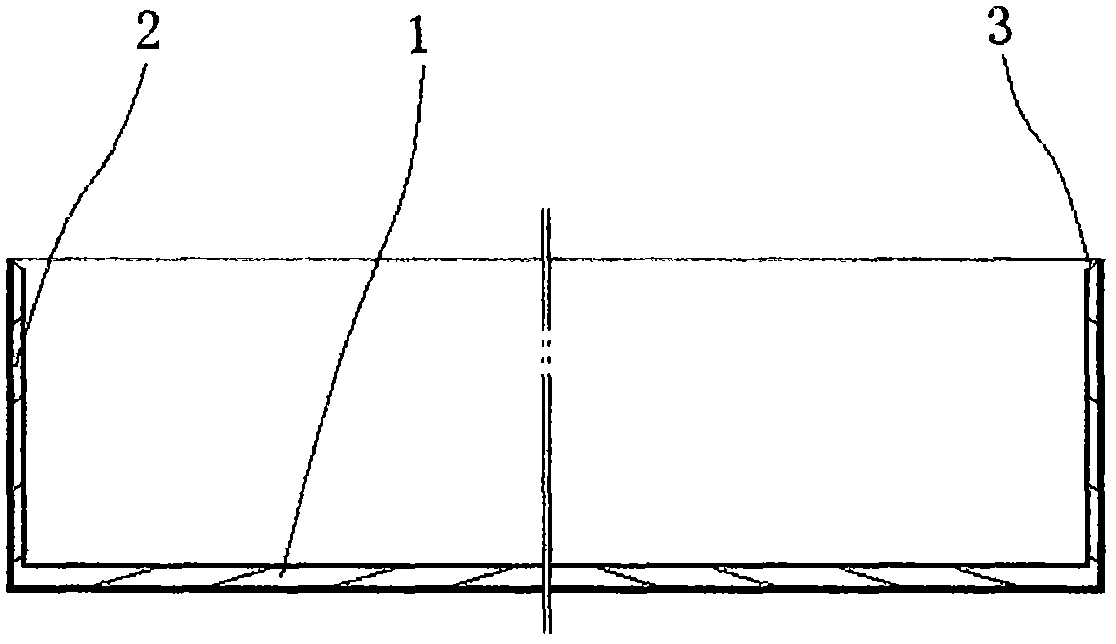

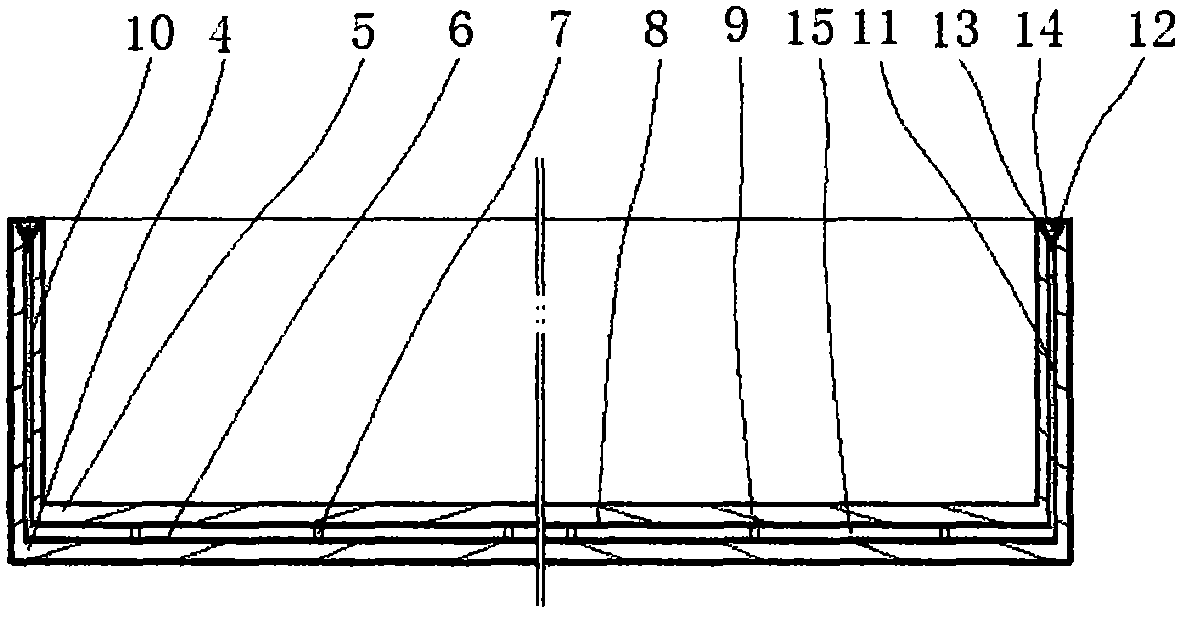

[0049] Embodiment one: according to Figure 1 , Figure II Shown to make:

[0050] (1) Make and shape the face wall toughened hem glass 4 and the inner wall toughened hem glass 5 of the single-sided opening made of the face wall 1, the hem 2 and the hem sealing surface 3 respectively, the length of the inner wall toughened hem glass 5 , The outer width dimension is smaller than the length and width inner dimension of the wall-folding glass 4 by 0.05mm-5mm.

[0051] (2) Place the tempered glass 4 facing the wall with the opening facing upwards, and place the pin 7 at the corresponding position on the inner surface 6 of the facing wall.

[0052] (3) Place the outer surface 8 of the inner wall tempered hemming glass 5 on the upper surface 9 of the pin, and make the inner wall tempered hemming glass hemming outer surface 10 meet with the face wall tempered hemming glass hemming inner surface 11 or leave a 0.05 mm-5mm clearance.

[0053] (4) Place the melting temperature at 300...

Embodiment 2

[0055] Embodiment two: according to Figure three Shown to make:

[0056] (1) Place the tempered glass 4 facing the wall with the opening facing up in water, tin or powder 16, and make the surface of water, tin or powder 16 inside and outside the workpiece higher than the outer surface of the tempered glass 5 on the inner wall by 3mm- 30mm. Then, the sealing heating device is turned on again, and the sealing low-temperature sealing material 14 is heated locally at 300°C-450°C in a manner of gradually increasing the temperature, so that the sealing low-temperature sealing material 14 melts and realizes the hemming with the inner wall tempered hemming glass of sealing.

[0057] (2) Take out the sealed workpiece from water, tin or powder 16, vacuumize the vacuum layer 15 through the vacuum hole 17, and turn on the vacuum after the vacuum degree of the vacuum layer 15 reaches the set vacuum degree The hole sealing device is used to locally heat the vacuum hole 17 to melt the lo...

Embodiment 3

[0058] Embodiment three: according to Figure four The schematic diagram of the product structure shown:

[0059] (1) After placing the column pin 7 at the corresponding position on the inner surface 6 of the wall, place a pre-formed separation layer 19 on the upper surface of the column pin 7, the separation layer hem 20 is in contact with the inner surface 11 of the tempered glass hem hem of the wall or Leave a gap of 0.05mm-5mm.

[0060] (2) Place the second-layer pins 7-1 on the corresponding positions on the upper surface of the separation layer 19, and align the second-layer pins 7-1 with the pins 7 up and down, and repeat this to form a multi-vacuum layer structure.

[0061] (3) Place the outer surface 8 of the inner tempered hemmed glass 5 on the upper surface of the upper pin, and make the inner wall tempered hemmed glass hemmed outer surface 10 meet the separation layer hem 20 or leave a gap of 0.05mm-5mm .

[0062] (4) Place the melting temperature at 300°C-450°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com